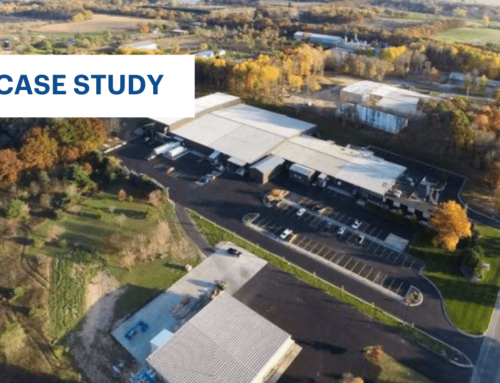

Akron Sewer Maintenance Facility

Project Details:

Owner: City of Akron – Sewer Maintenance Division

General Contractor: G. Stephens, Inc.

Duration of Work: 4 weeks

Subsurface Conditions: Sand and silt fill overlaying damp to wet sand and silt on top of saturated medium dense sand and silt.

Approximate Key Quantities: 126 Bi-modulus Columns (BMC)®, 164 Controlled Modulus Columns (CMC)® rigid inclusions.

Project Overview:

The City of Akron needed ground improvement to support a new building replacing an existing Akron Sewer Division maintenance facility. The new facility consists of large garage area and office space totaling 31,200 sq ft. Vibrations caused by traditional deep foundation techniques were a major concern of the clients due to underground utility lines running throughout the site.

Menard was approached by the geotechnical engineer, general contractor, and the City of Akron to design an economical and innovative ground improvement solution as an alternative to aggregate piers or piles. A combination of Controlled Modulus Column (CMC)® rigid inclusions and Bi-Modulus Columns (BMC)® were designed to support the footings and slabs of the new facility. These techniques offer minimal vibrations and required a thinner Load Transfer Platform (LTP) as compared to an all CMC approach resulting in cost savings for the client.

Ground Conditions:

The site soils consist of up to 5 ft of sand and silt fill, overlaying a 5 to 15 ft layer of damp to wet sand and silt with minor organics, on top of a 15 to 30 ft layer of saturated medium dense sand and silt.

Solution:

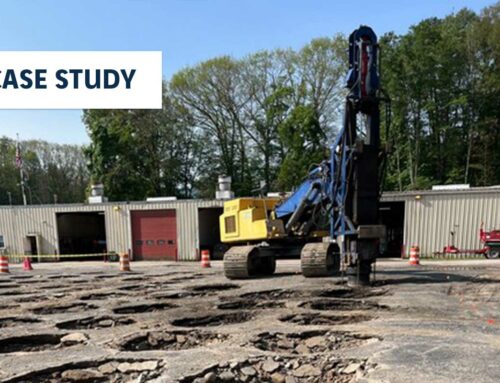

Numerous underground utility lines running throughout the site posed a challenge to drilling operations. Buried in the shallow wet sand layer, there was also a large, decades-old culvert that could not withstand vibrations that occur with some traditional foundation techniques. Menard designed a dual system of CMC rigid inclusions and BMCs to accommodate the challenging layout of the utility lines, the vibration requirements of the culvert, and to support the footings and slabs of the new maintenance facility.

A total of 164 CMC rigid inclusions were installed to support the footings, and a total of 126 BMCs were installed to support the slab of the new facility. This combination also resulted in the reduction of the thickness of the LTP, saving the client money.

Mobilizing the two rigs that are required for BMC installation was also a challenge due to the smaller size of the construction site. To achieve the optimal BMC transition zone – the area of overlapping stone and grout – efficient coordination of the rigs was required so the grout would not set before the stone column was installed on top of the grout column.

The combination of CMC rigid inclusions and BMCs offered a higher degree of control and proved to be a more cost-effective alternative over aggregate piers and traditional foundation techniques in the soft soil conditions.

Print this resource