Vibrocompaction is a ground improvement solution that densifies the ground by imparting vibration at depth using a vibratory probe. It is used to control and reduce settlement, mitigate liquefaction, stabilize or treat hydraulic fill and limit lateral earth pressure behind quay walls.

Key Elements

WHAT IS IT?

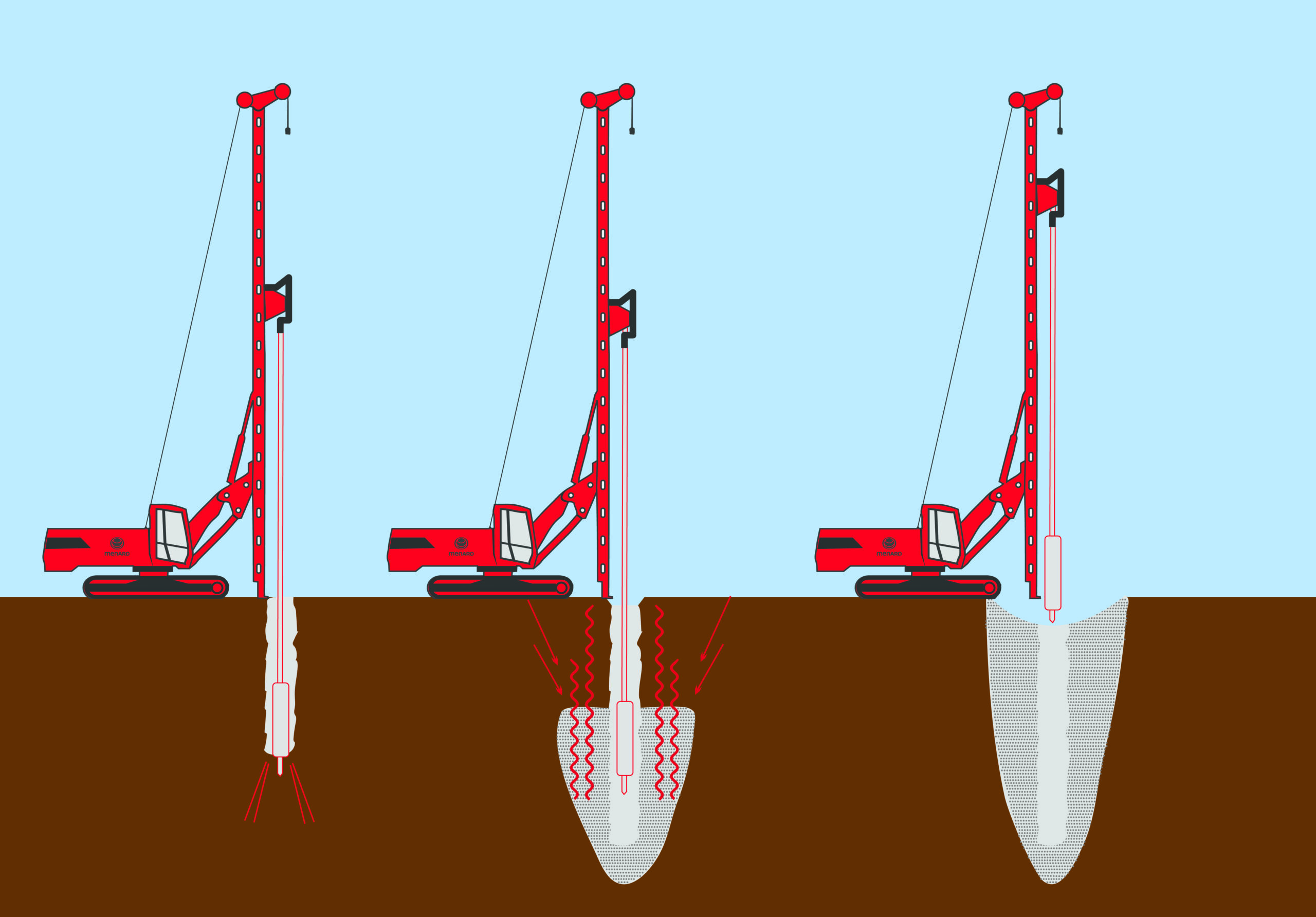

The in-situ compaction of loose granular soils by penetration of a vibratory probe or vibroflot resulting in localized liquefaction, an almost immediate settlement and overall improvement of the characteristics of the surrounding soils.

HOW DOES IT WORK?

Loose soil or fill can be compacted at depth through insertion of vibrating probes together with the addition of large volumes of water to enable the soil particles to rearrange in a denser formation and thus increases the overall density of the layer. Vibrocompaction can only be used on extremely clean (relatively fines-free) granular soils and its effectiveness is very sensitive to the presence of silt and clay.

WHY USE IT?

Mitigate the risk of liquefaction and densify loose granular soils—often used for the compaction of hydraulic fills in large, reclaimed areas.

Vibrocompaction is executed using a vibrating probe supported by a crane, drill rig, or excavator. The vibratory probe is advanced to the target depth under its own weight with the assistance of vibration, water jetting and in some cases pull down of the supporting base machine.

Advantages of Vibrocompaction Include:

- Economical, particularly for large-footprint sites where clean granular soils are present

- If clean soils are present at the surface and lowering of the site elevation is desired, vibrocompacion can be performed without the importation of fill materials

- Allows ground improvement to be performed without the use of stone or grout, resulting in a relatively low carbon footprint

- Because densification is being delivered by probes or vibratory flots, deeper densification can be achieved as compared to surficial methods such as dynamic compaction or rapid impact compaction