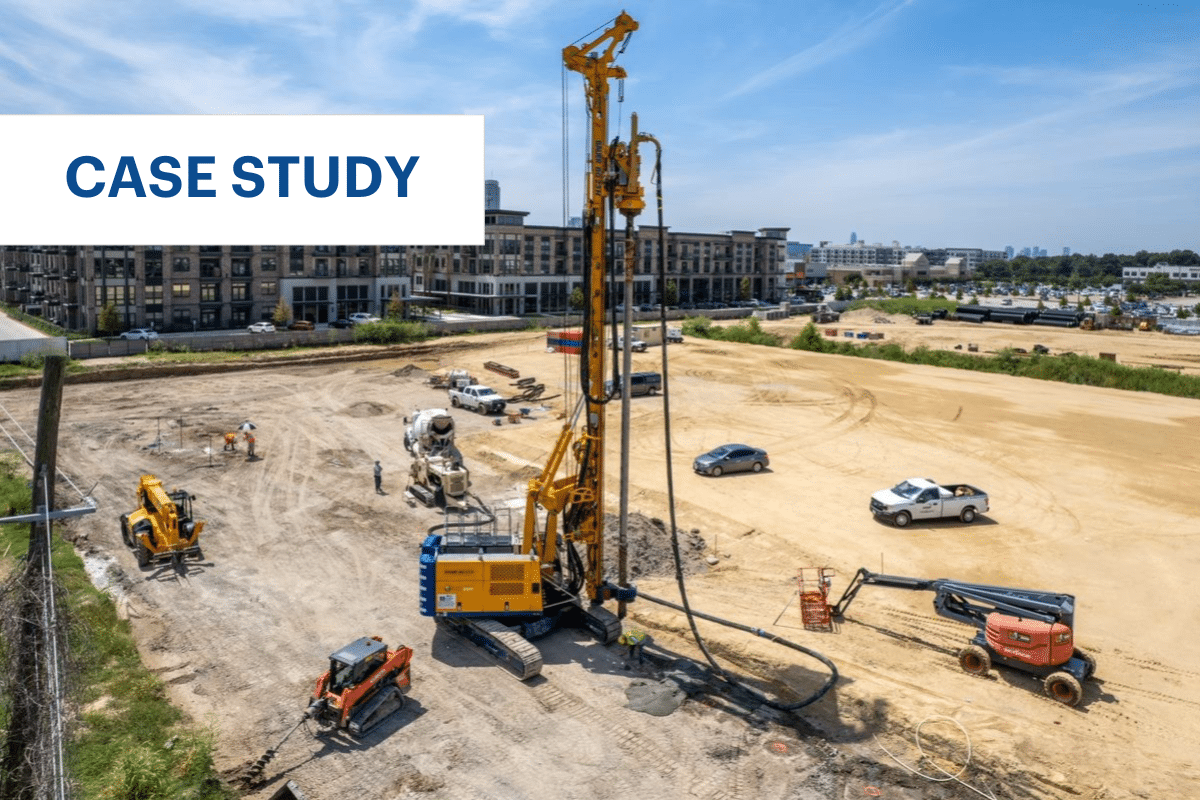

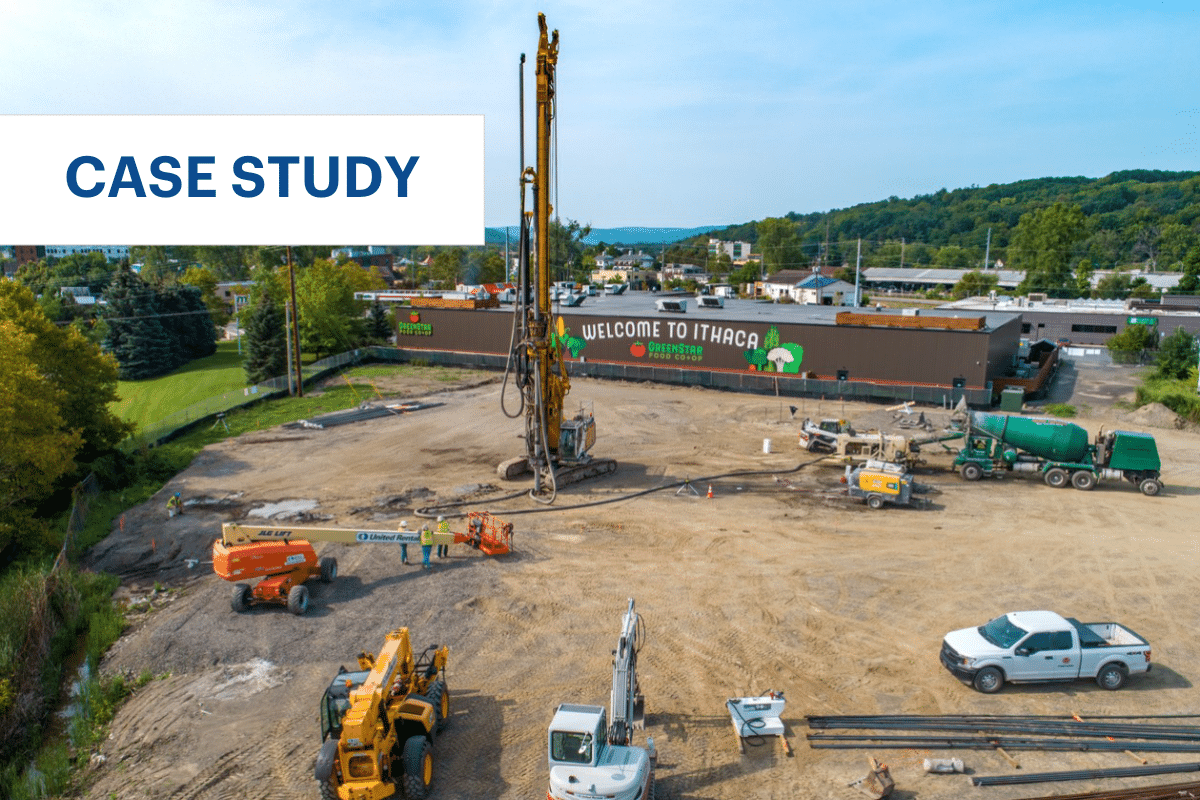

Controlled Modulus Column (CMC)® Rigid Inclusions for Ground Improvement

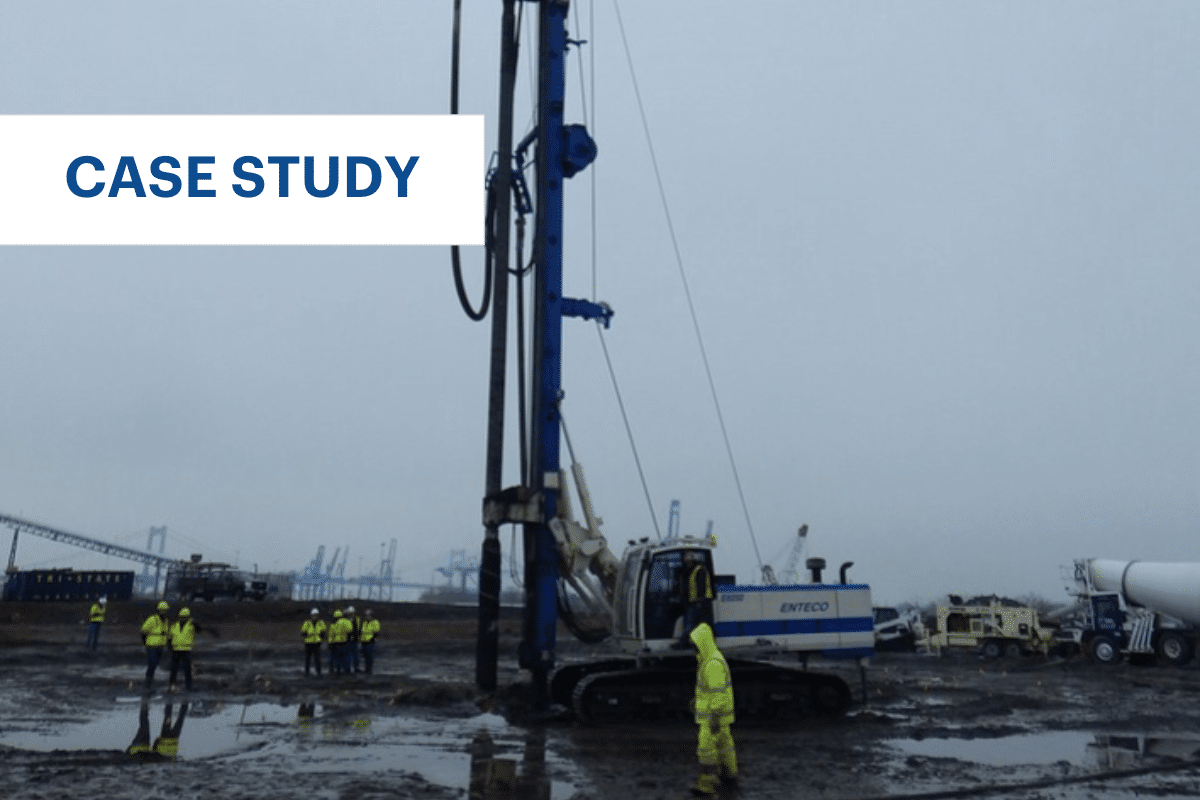

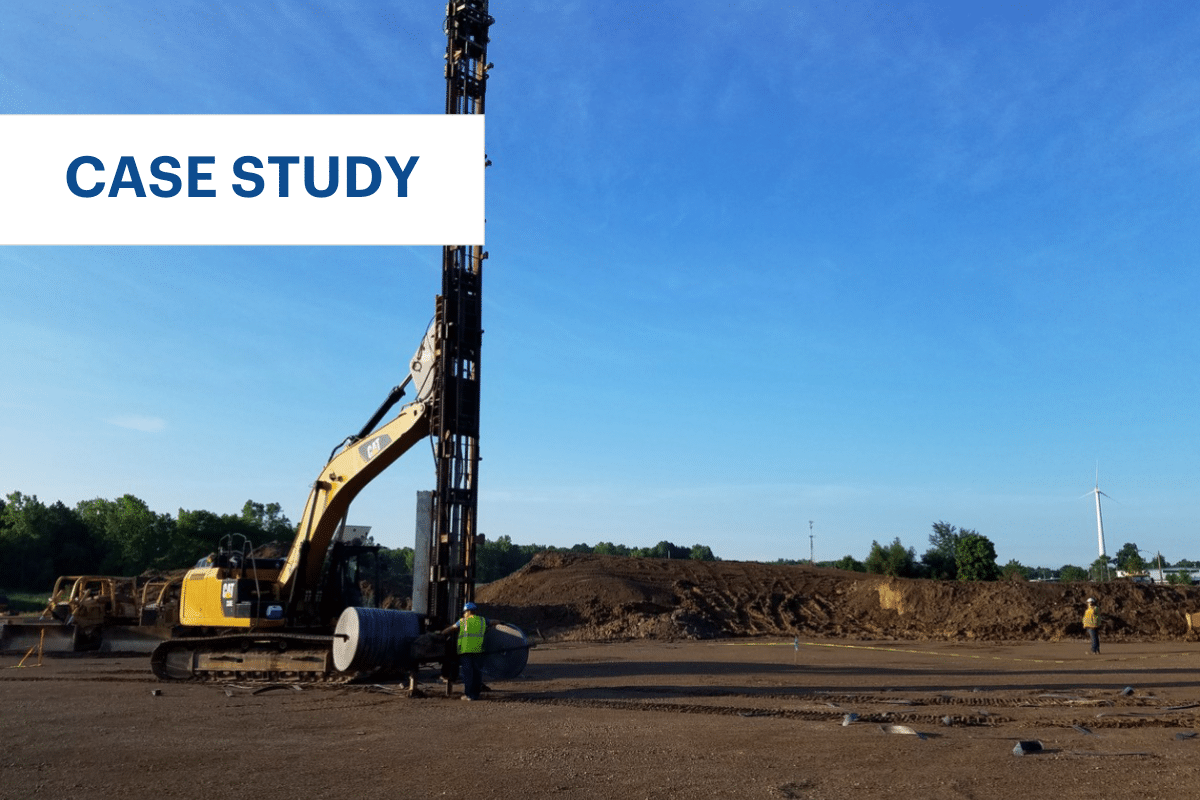

Controlled Modulus Columns (CMC)® Rigid Inclusions are vertical, grouted elements for ground improvement that typically range in diameter from approximately 12 inches to 18 inches.

CMCs were developed by Menard’s French affiliate, Menard Soltraitement, in 1994 and were patented in the US in 1999. Menard’s first CMC project in the USA was for the support of a Lowes Home Improvement Store in South Burlington Vermont. Since that time, with the industry-wide acceptance of CMC, the technique is now generically referred to as rigid inclusions.

Key Elements

WHAT ARE CMCs?

Robust vertical ground improvement elements made of a rigid inclusion installed using displacement tooling.

HOW DO CMCs WORK?

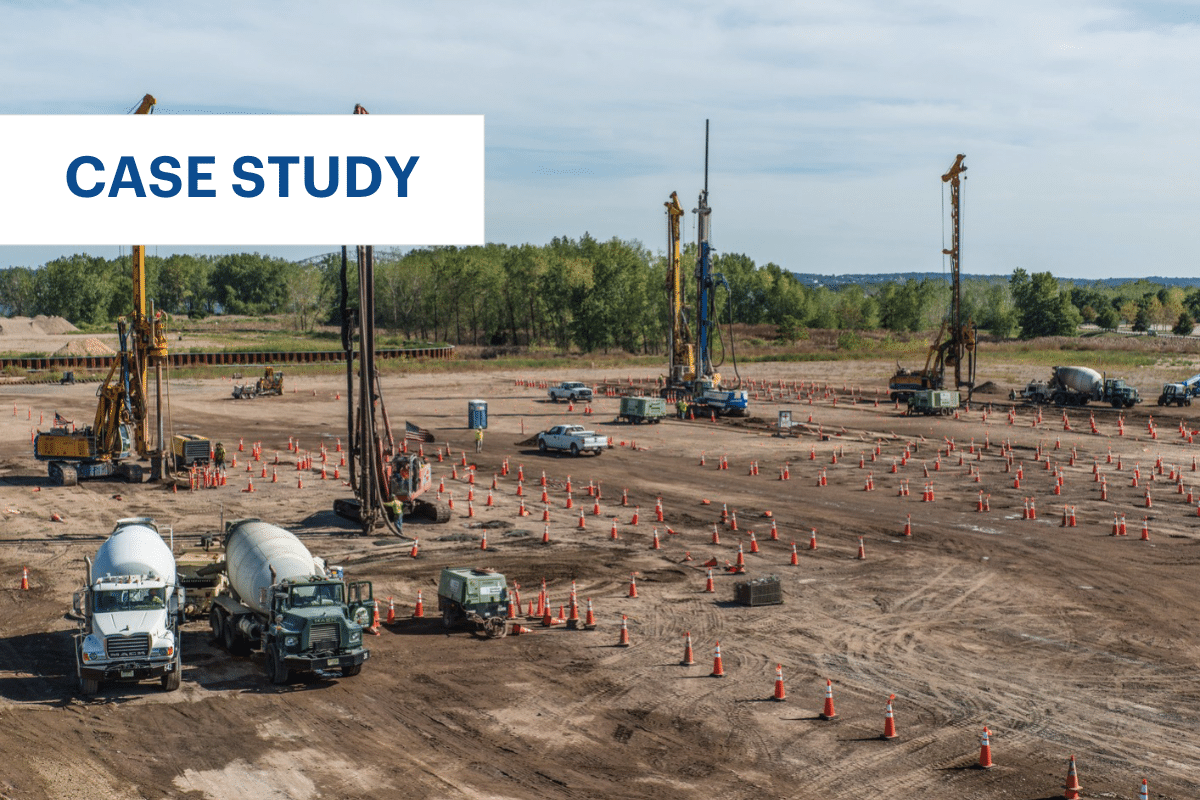

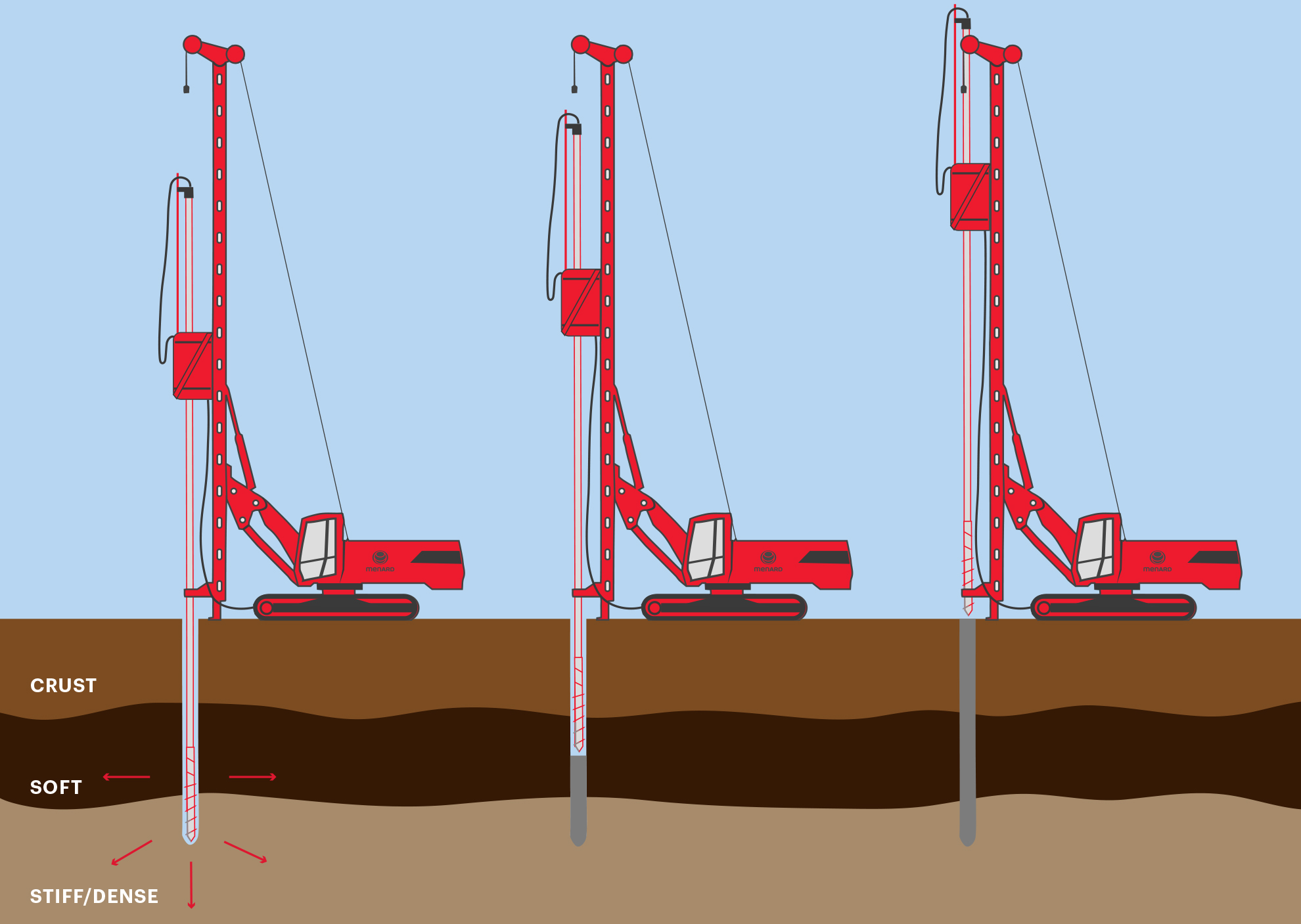

Combined with a load transfer platform (LTP) typically made of compacted granular material, the elements work as a system with the surrounding soils to improve the stiffness of the ground, transferring the load of the structure through the soft soils into a competent bearing layer.

WHY USE CMCs?

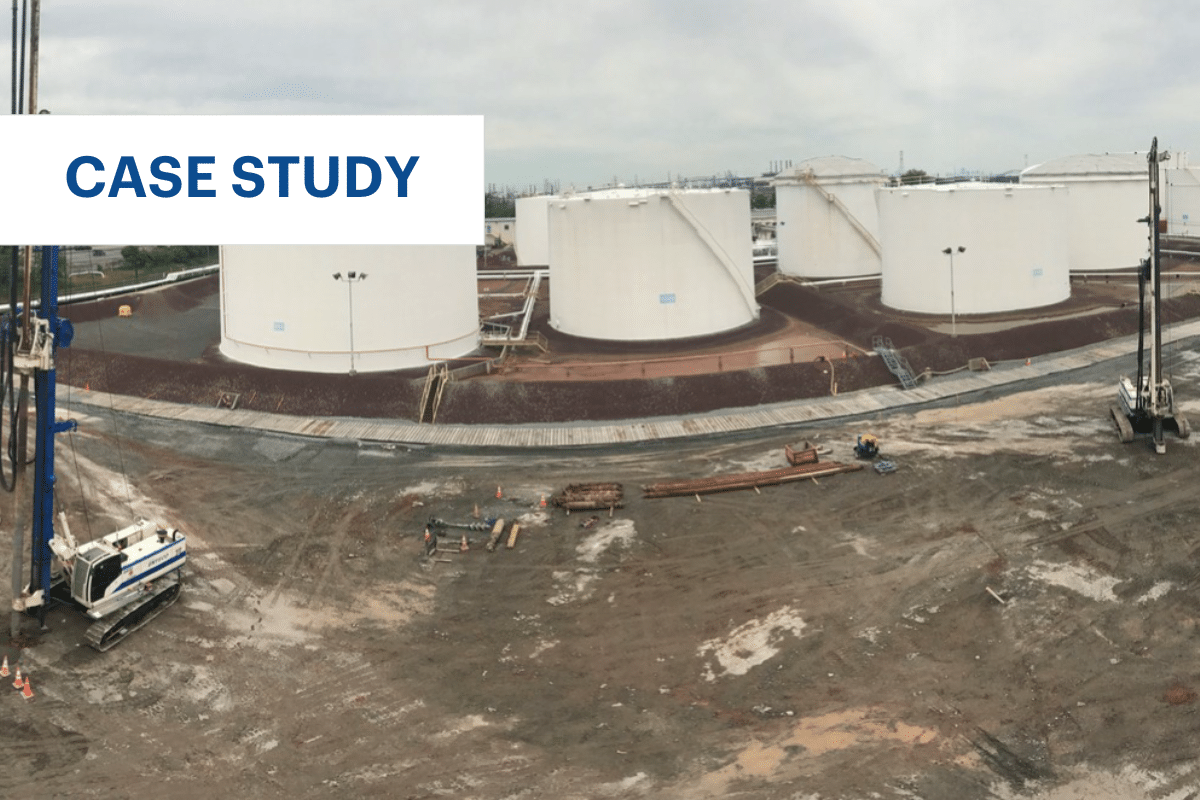

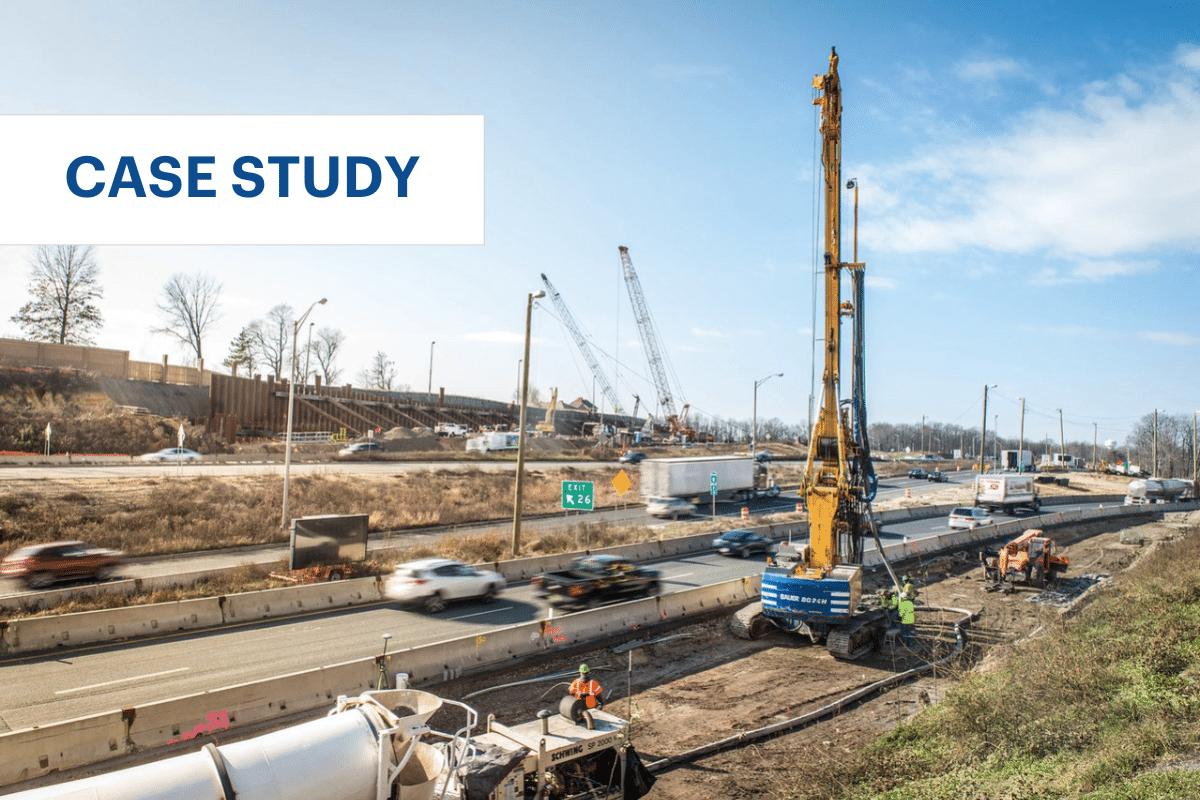

Increase bearing capacity, reduce long-term settlements under light to heavy loads in most types of ground. Very effective in spanning very soft layers. Because minimal spoil is generated during installation, CMCs are also ideal for sites with contamination.

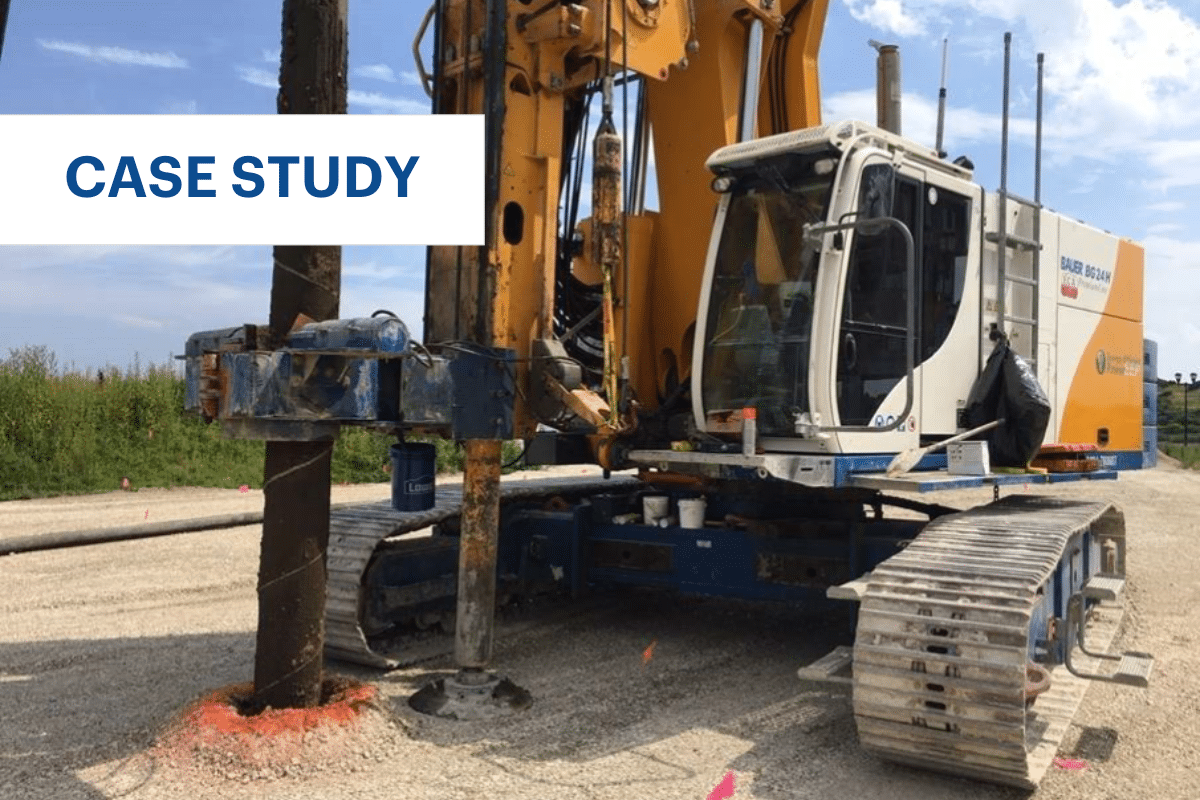

Controlled Modulus Columns (CMC)® are grouted columns formed using specially-designed tooling that displaces soil laterally, producing very little spoil. As the auger is extracted, a column of cement-based grout is formed.

Advantages of CMCs Include:

- Effective in very soft soils

- Can be installed to extremely deep depths

- High load carrying capability

- Only minimal spoils generated during installation

- Does not provide a pathway for groundwater contamination migration

Download our CMC technique sheet: