Gerber Manufacturing Plant

Gerber Manufacturing Plant

Project Details:

Owner: Nestle Nutrition

General Contractor: Dan Vos Construction Company

Date of Work: January 2013 - February 2013

Engineer: JDH Structural Engineering and SME - Soil and Materials Engineers, Inc.

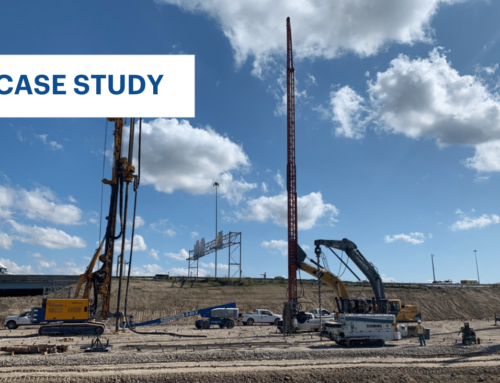

Approximate Key Quantities: Controlled Modulus Columns (CMC)® rigid inclusions - 987 EA

Project Overview:

Ground Conditions:

Solution:

The ground improvement at the site involved removing the existing slab, installing CMCs to support the footings and the slabs, filling back to the bottom of the slab and placing a 12-inch-thick concrete slab. The new slab is a slab-on-grade with a load of 400 psf and a maximum footing load of 670 kips for a 12-ft-square footing (4,650 psf bearing pressure).

The footings, grade beams and floor slab were supported by 987 CMCs that reached a maximum depth of 36.1 ft. The CMCs increased bearing capacity under the existing structures.

Despite tight working conditions inside of the existing buildings, all work was completed in one continuous phase with all quality control testing meeting specified requirements.

Print this resource