Essington Avenue Market

Essington Avenue Market

Project Details:

Owner: O’Neill Property Group

General Contractor: Merion Construction

Duration of Work: 28 weeks

Subsurface Conditions: Municipal solid waste with underlying organic silts

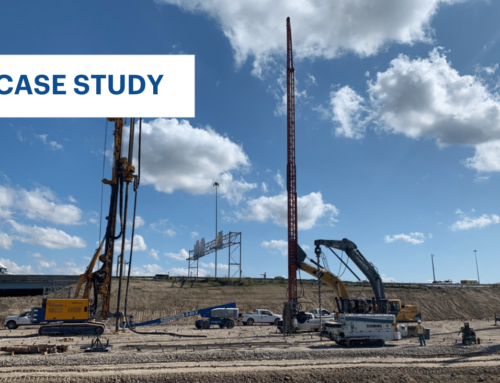

Approximate Key Quantities: 10,150 Controlled Modulus Columns (CMC)® rigid inclusions

Project Overview:

Ground Conditions:

Solution:

The foundation system was originally designed for driven piles with heavy pile caps and a reinforced structural concrete suspended floor slab up to 12 inches thick. Menard’s alternative design proposed CMC rigid inclusions to support the entire facility, including the loading dock apron around the building perimeter. The most significant advantage of the alternate design was two-fold: 1) the change from a structural floor system to a thinner slab-on-grade with conventional spread footings, and 2) a simpler and more continuous vapor membrane with minimal sealed penetrations to enhance quality, reliability and cost of the vapor barrier over the MSW.

At the time of construction, this was the largest CMC rigid inclusion project in the United States. Menard has since surpassed this record on numerous projects.

Print this resource