Fort Belvoir Community Hospital

Fort Belvoir Community Hospital

Project Details:

Owner: Fort Belvoir Community Hospital

General Contractor: Turner Construction Company/Gilbane Building Company Joint Venture

Duration of Work: 29 weeks

Subsurface Conditions: Stiff to hard low plastic and high plastic clays with varying amounts of sand

Approximate Key Quantities: 4,900 Controlled Modulus Columns (CMC)® rigid inclusions

Project Overview:

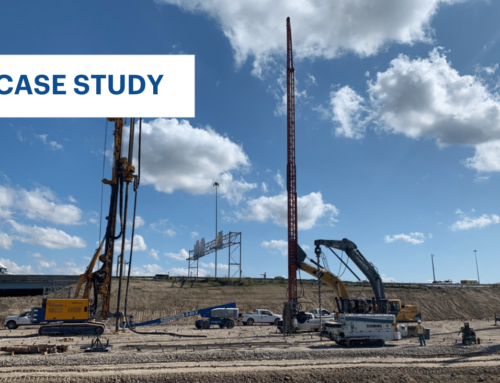

The Fort Belvoir Community Hospital is part of an integrated health care network providing medical services to the nation’s wounded soldiers and their families. The $800 million, 1.3 million square foot military construction project, managed by the Corps of Engineers, was fast-tracked as part of the 2005 Base Realignment and Closure program. The project required ground improvement to support the high-bearing load of the facility, which is a series of five, multi-story buildings connected to form one structure, plus two parking garages – one anchoring each end.

Due to the aggressive schedule, Menard proposed an alternative solution to rammed aggregate piers by using Controlled Modulus Columns (CMC)® rigid inclusions, an economical technique for strengthening the ground and increasing its load bearing capacity, while allowing for faster installation and improved sustainability via limited site import/export.

Ground Conditions:

Solution:

The Corps had designed spread footings for the project with a specified bearing capacity varying between 7,000 and 8,000 psf depending on the structure. Since the buildings were built near existing grade or cut down in some locations, no significant settlement was expected below the slab-on-grade, so no ground improvement was required under the slabs.

Menard went through a rigorous design process to demonstrate that the CMC rigid inclusions would work at high-bearing pressure and still meet the performance criteria for settlement and bearing capacity. The design team ran a series of proprietary Menard footing settlement calculation models and confirmed the analysis with a third-party review using a 3-D finite element model. Menard designed a dense array of CMC rigid inclusion elements under each foundation support and a load transfer platform between the CMC rigid inclusions and footings to eliminate any physical connection between the ground improvement system and the structure.

More than 4,900 CMC rigid inclusions were installed at a maximum depth of 29.5 feet for a total of 63,322 linear feet.

Print this resource