Allegheny Health Network McCandless

Project Details:

Owner: Allegheny Health Network

General Contractor: Rycon Construction

Duration of Work: 20 weeks

Subsurface Conditions: Soft to stiff clay with some sand and silt. Underlying the clay was shale bedrock.

Approximate Key Quantities: 177 Controlled Modulus Column (CMC)® Rigid Inclusions

Project Overview:

To emphasize its “patient-centered” care philosophy, Allegheny Health Network (AHN) embarked on the construction of several neighborhood hospitals in the suburban Pittsburgh area. McCandless, located north of downtown, was selected as one of the sites. Unlike standalone emergency departments or urgent care centers, AHN McCandless would be a fully licensed small-format hospital open around the clock.

In addition to an emergency department and 10-bed inpatient unit, the hospital would provide diagnostic imaging, as well as laboratory and other complementary services. Staffed by board-certified physicians, nurses and other experienced health care professionals, AHN McCandless would be home to AHN’s women’s health services. Due to the compressible nature of the soils at the site, Menard USA was contracted to provide support for a newly constructed 49-ft high retaining wall that was necessary to increase the surface parking area for the proposed hospital.

Ground Conditions:

The soils consisted of soft to stiff clay with some sand and silt. Underlying the clay was shale bedrock, which was the tipping strata for Menard’s method of ground improvement, Controlled Modulus Column (CMC)® rigid inclusions.

Solution:

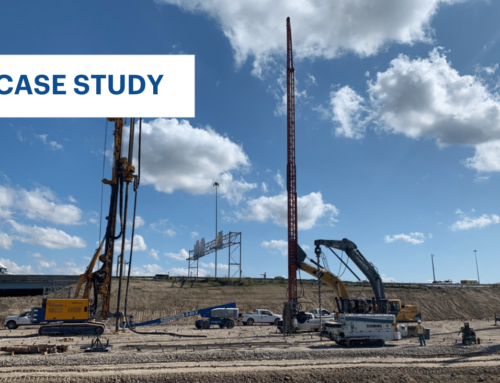

Due to the topography of the site, the significant feature in installing the retaining wall was that it was founded on two elevations: The lower bench at 1,097 ft; the higher bench ranged from 1,129 ft to 1,140 ft. CMCs were preferred by both the geotechnical engineer and general contractor for cost-effectiveness and for reducing the work schedule. The job, done in two phases, was complete in two work weeks, one week per phase.

Among the most significant challenges faced by Menard’s team was the elevation of the lower bench which required the drill rig to navigate an extremely steep access ramp to reach the lower elevation. Moreover, the working bench was relatively narrow and drill rig maneuvering was restricted. Menard installed 70 CMC rigid inclusions in the lower bench and 107 CMC rigid inclusions in the upper bench. The average depth was 18 ft and maximum depth was 31 ft. Menard’s design showed settlement beneath the wall would be 1 in or less, meeting the Engineer’s performance criteria for the parking lot.

To support the construction of a 49-ft retaining wall that would increase the surface parking area for a proposed hospital, Menard USA installed 177 CMC rigid inclusions. The project was completed in a safe and timely manner with excellent coordination between Menard, the general contractor and the geotechnical engineer.

Print this resource