Goya Foods Warehouse & Headquarters

Goya Foods Warehouse & Headquarters

Project Details:

Owner: Goya Foods

General Contractor: RC Andersen, LLC

Duration of Work: 18 weeks

Subsurface Conditions: Miscellaneous fill and debris over soft organic silt and peat underlain by a varved silt, clay and glacial till

Approximate Key Quantities: 11,400 Controlled Modulus Columns (CMC)® rigid inclusions

Project Overview:

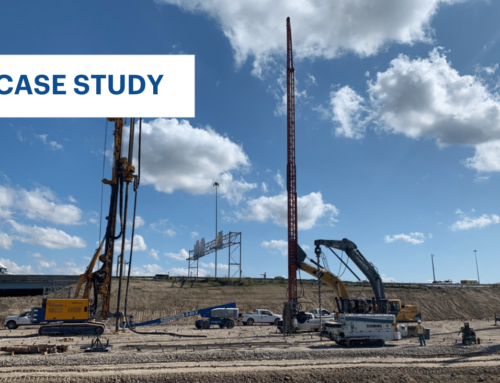

The Goya Foods warehouse and headquarters is a 615,000 square-foot facility in Jersey City, New Jersey. The cutting-edge manufacturing, production and distribution facility is built on a 40-acre former brownfield site that sustained flooding following Hurricane Sandy. To improve the ground, support the high surface loads, and minimize future settlements, Menard implemented a design-build ground improvement solution using Controlled Modulus Columns (CMC)® rigid inclusions.

Ground Conditions:

Solution:

Menard proposed CMC rigid inclusions to support the entire facility and to improve the soft soils allowing for spread footings and slab-on-grade construction. This ground improvement technique was critical to minimize contaminated soil removal at the site. CMC rigid inclusions are a preferred alternative for ground improvement at brownfield sites because they are installed using a specially designed auger that displaces the soil laterally, with very minimal spoils created.

The Menard solution consisted of the design and installation of thousands of CMC Rigid Inclusion elements to keep total and differential settlement within project tolerances. The slab loads were designed with an allowable bearing pressure of 1,100 psf, with footings designed at 5,000 psf. A large-scale area load test and four single-element load tests were performed to confirm critical components of the design.

Following schedule delays due to flooding from Hurricane Sandy, Menard used four rigs working simultaneously. Ultimately, the project was completed a month ahead of schedule.

Print this resource