Plains Utica

Plains Utica

Project Details:

Owner: Plains All American Pipeline, L.P.

General Contractor: Kelley Construction, Inc.

Duration of Work: 9 weeks

Subsurface Conditions: Slag and silty-sand over lean clay over dense sand and gravel

Approximate Key Quantities: 700 Bi-Modulus Column (BMC)® and stone columns

Project Overview:

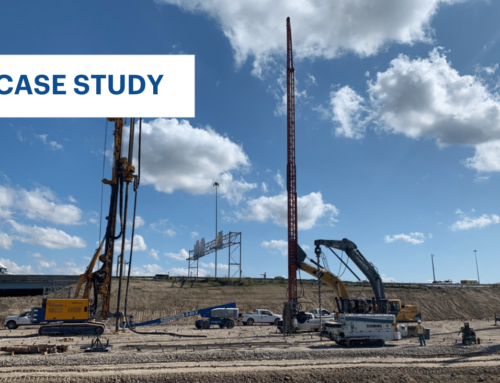

Plains All American Pipeline selected a site in eastern Ohio along the Ohio River to construct a storage and transfer facility, which included a marine docking station for barges transporting Utica formation gas down the Ohio River. A subsurface site analysis concluded that the soil conditions were not adequate to support the weight of the two new gas storage tanks to be built as part of the new facility. To support the foundation and ringwall of these two new storage terminals, Menard proposed a ground improvement solution of Bi-Modulus Column (BMC)® underneath the tank floors, and stone columns (SCs) directly below the ringwall. The use of these techniques eliminated the need for a Load Transfer Platform (LTP), resulting in cost- and time-savings for the client.

Ground Conditions:

Solution:

To support the foundation and ringwall of the two new storage tanks, Menard implemented an innovative solution of BMCs and SCs. This eliminated the need for an LTP, saving the client time and money. A total combination of approximately 700 BMCs and SCs were installed up to a maximum depth of approximately 62 feet. Two single-element static load tests were performed on the test elements to confirm the design bearing capacity.

The former concrete foundations were removed prior to installation of the BMC elements; however, slag and debris in the subsurface resulted in difficult drilling conditions. To keep production on schedule, Menard pre-drilled prior to the installation of the ground improvement elements. A post-construction hydrotest was performed by the client on the completed storage tanks and no settlement was observed.

By using a BMC and SC solution, Menard was able to save the client time and money while meeting the design requirements for bearing capacity and settlement.

Print this resource