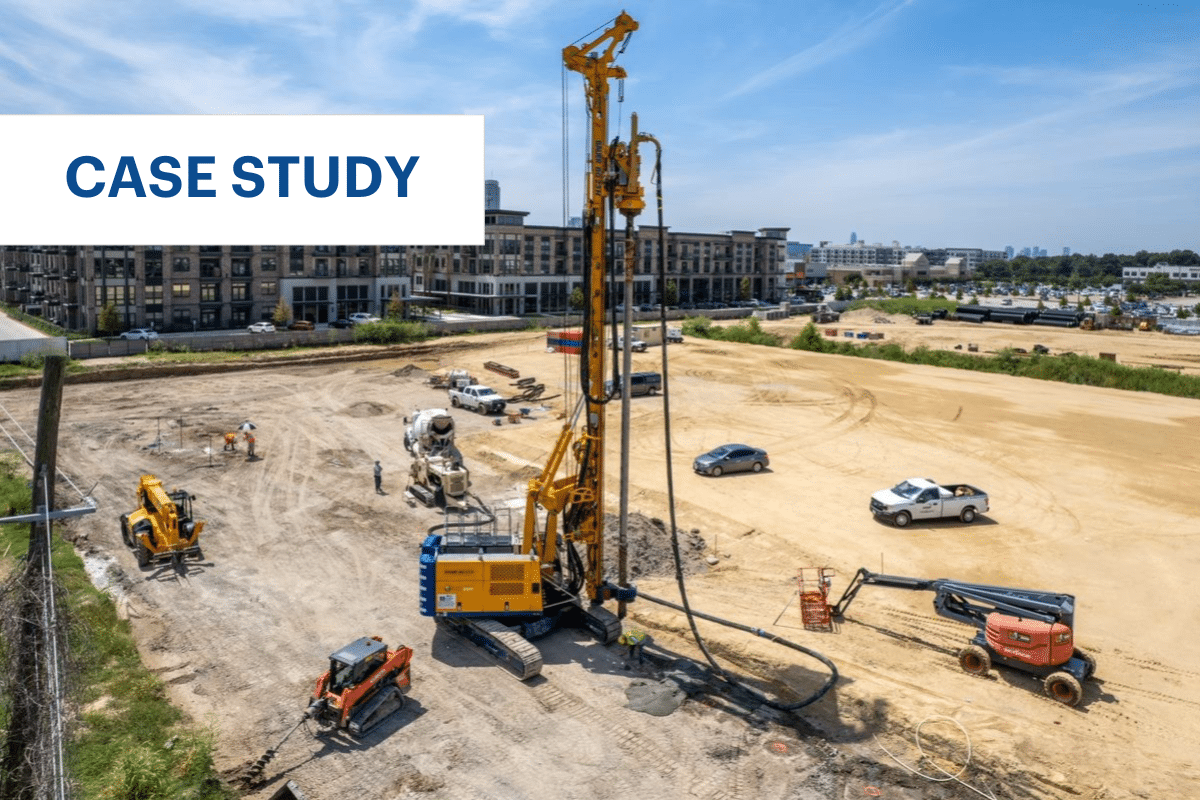

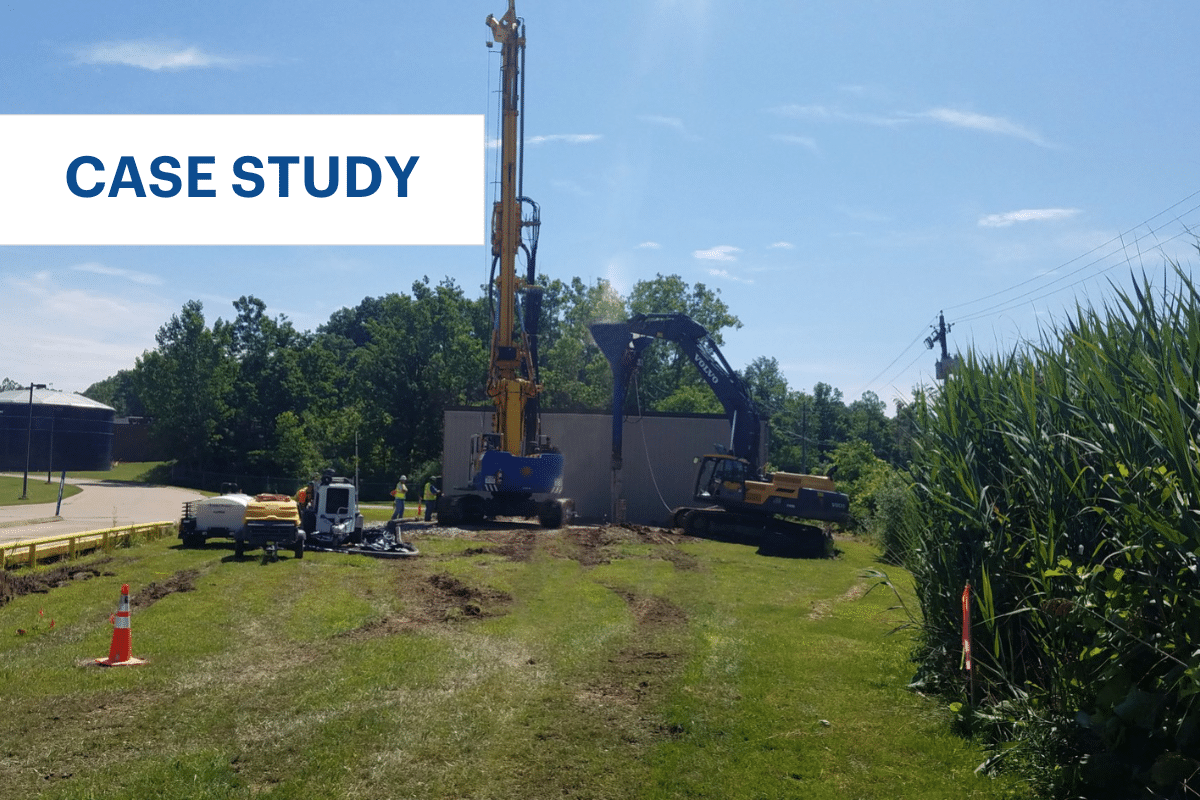

Bluestone Rail Facility

Project Details:

Owner: Markwest Energy Partners

General Contractor: Markwest Energy Partners

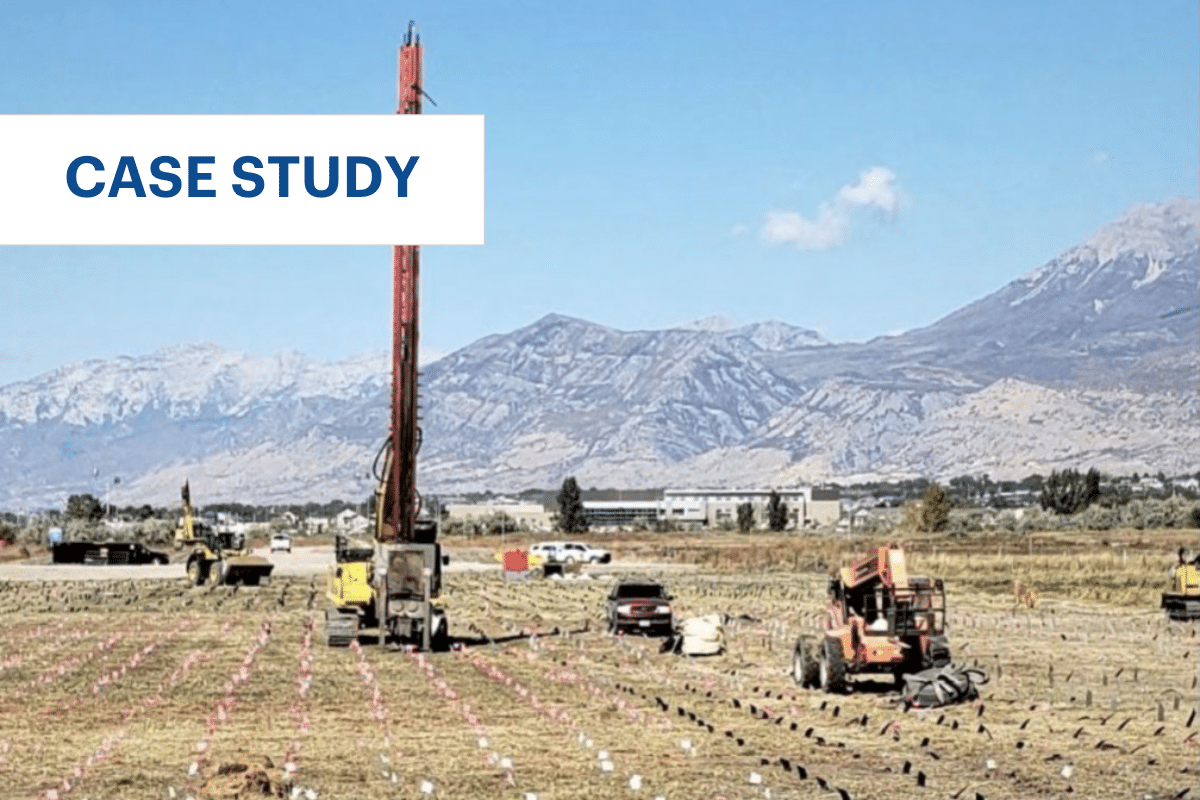

Duration of Work: 4 weeks

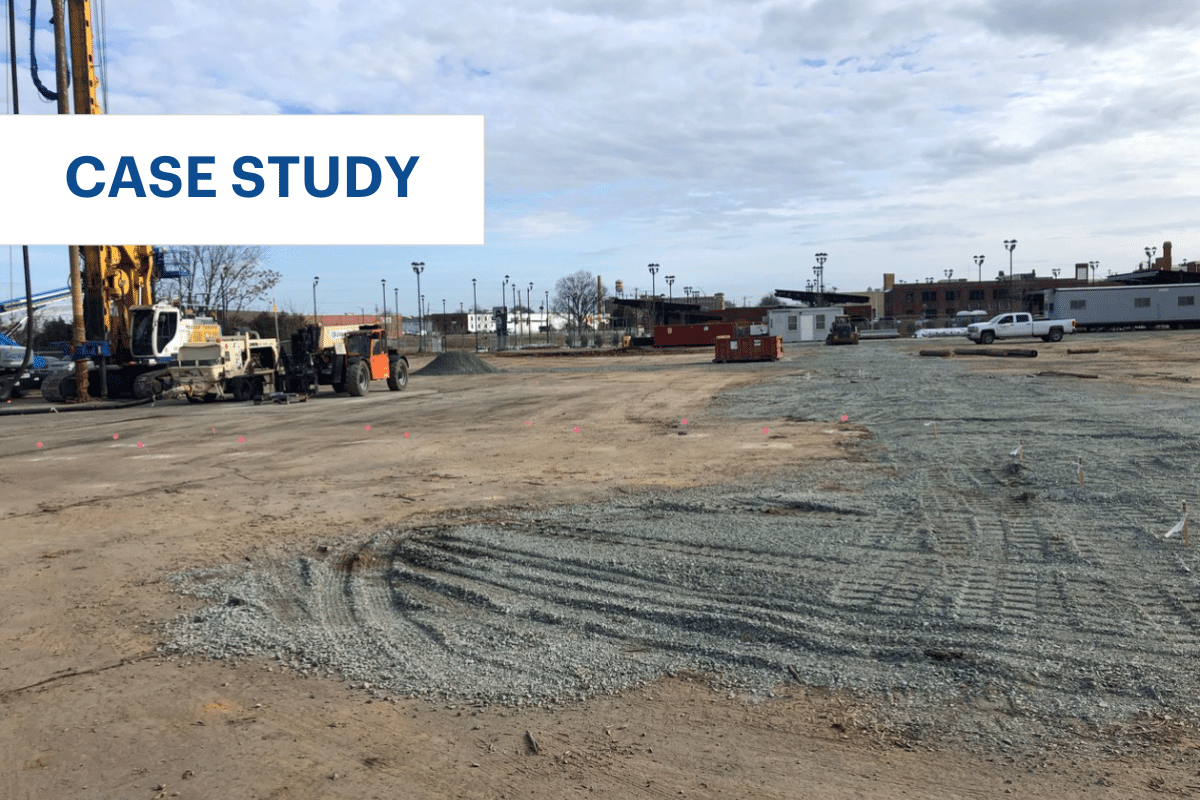

Subsurface Conditions: 20-50 ft of mine spoil, underlain by alluvial deposits, dense residual soils and shale bedrock.

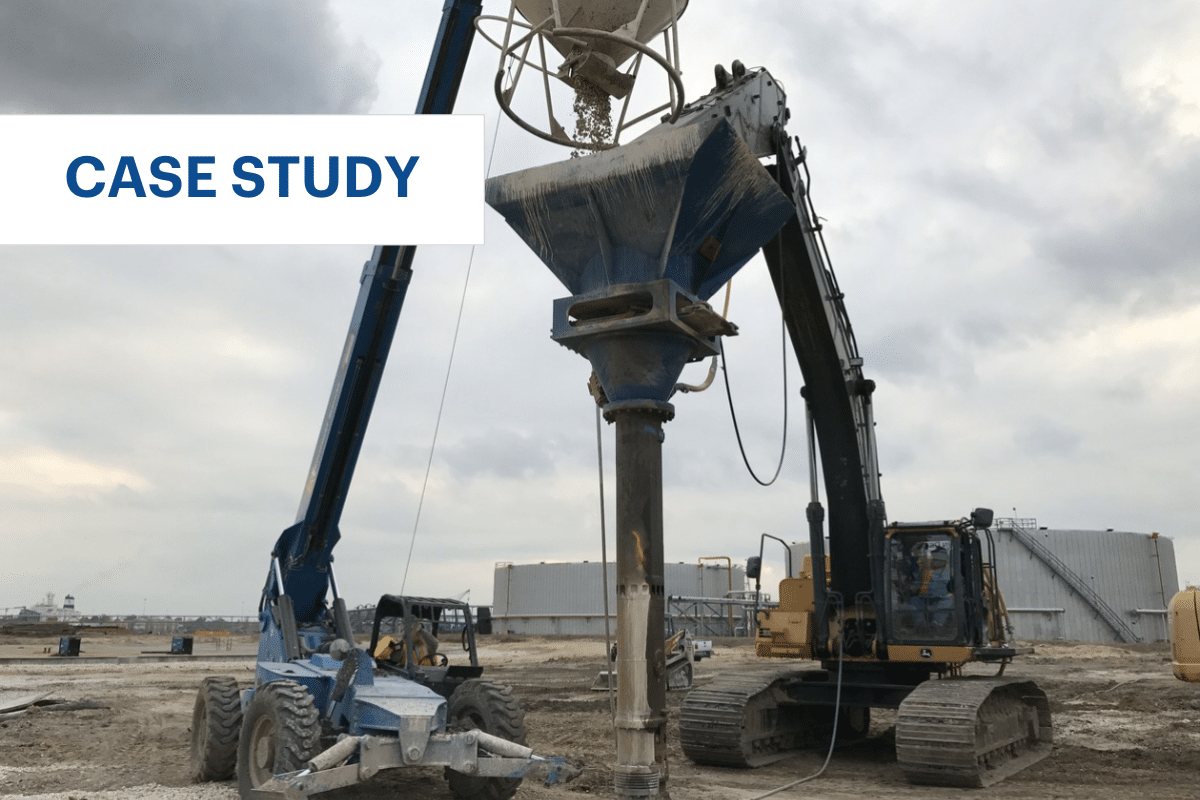

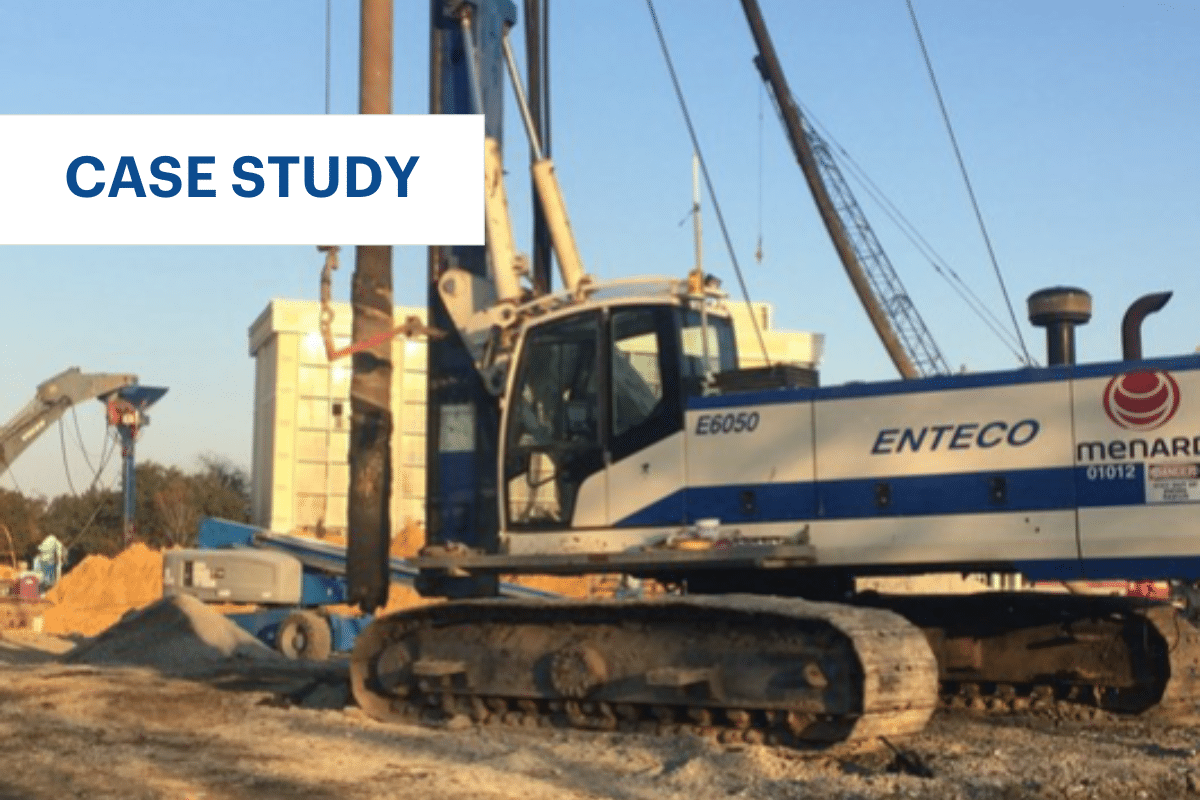

Approximate Key Quantities: 496 Controlled Modulus Column (CMC)® Rigid inclusions

Project Overview:

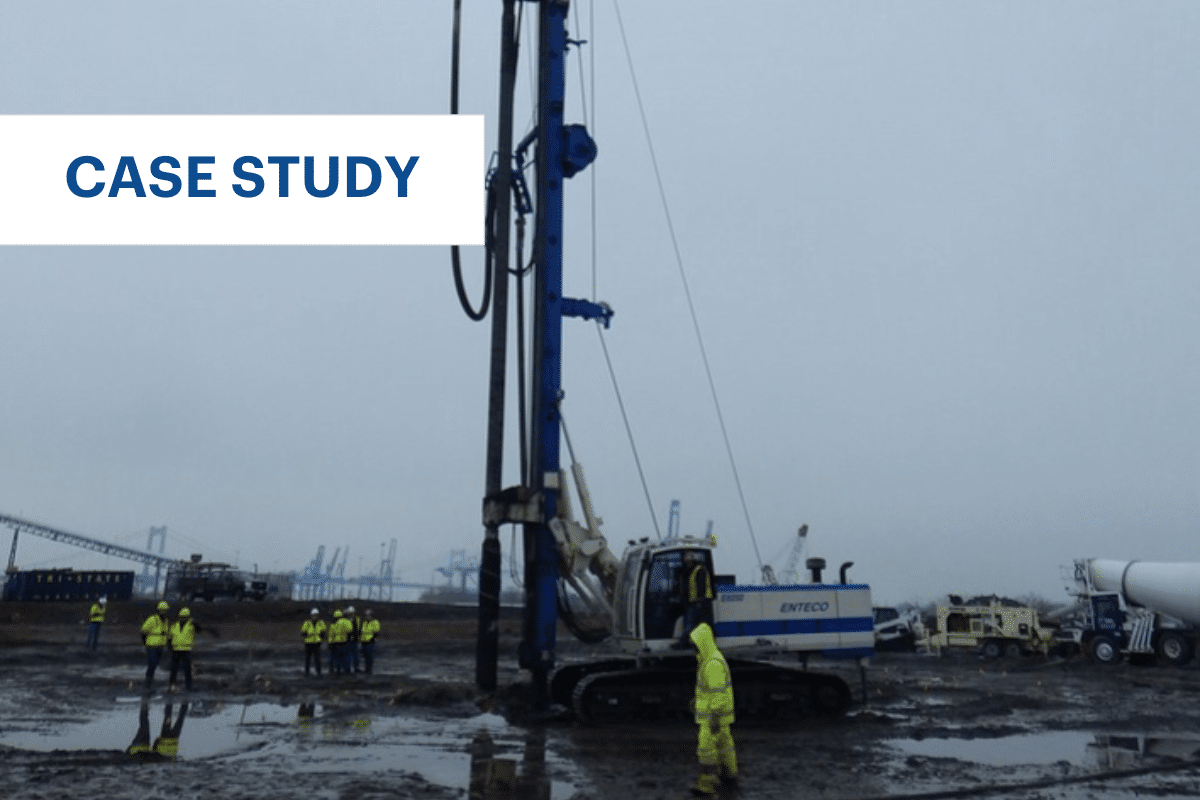

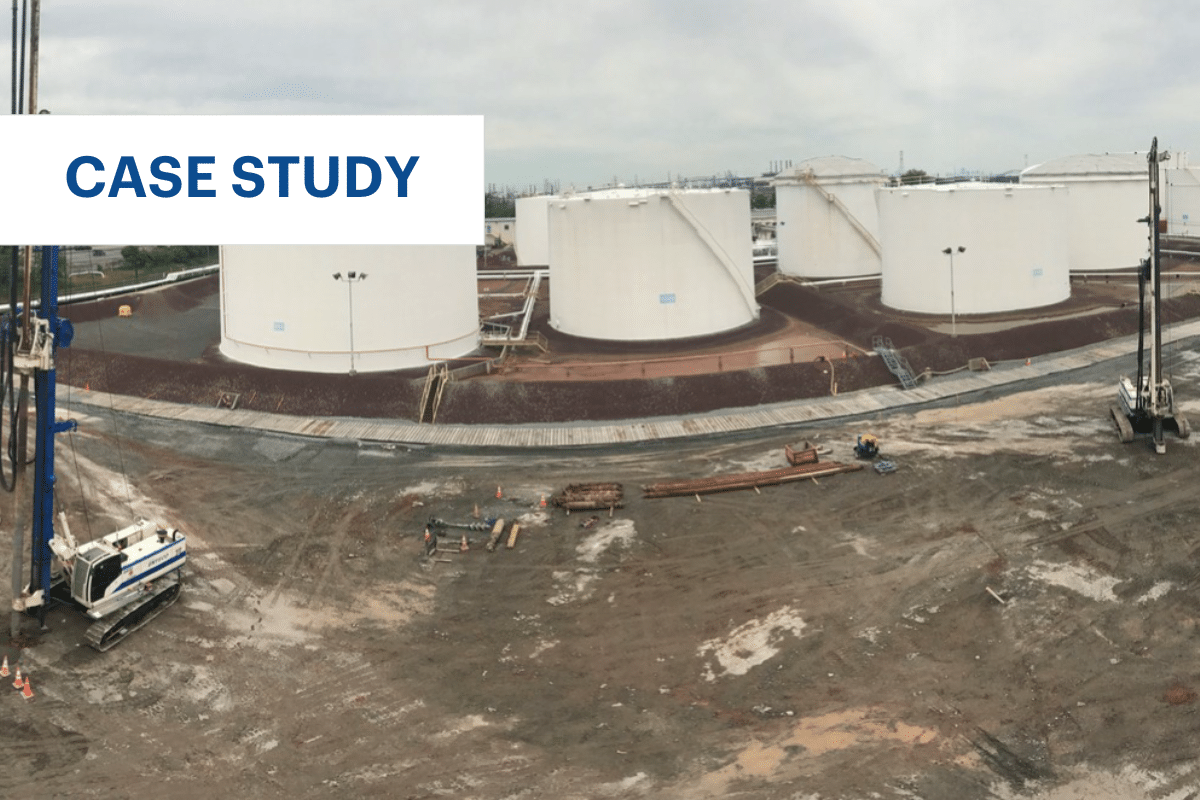

A rail facility containing two fire-protection tanks, 27 liquefied natural gas storage tanks and a pipe bridge crossing an existing rail line was proposed for a mid-stream gas processing facility, located 30 miles outside of Pittsburgh.

Given the considerable storage capacity and weight of the tanks, and considering the variable nature and compressibility of the soils, excessive settlement was predicted unless ground improvement was provided.

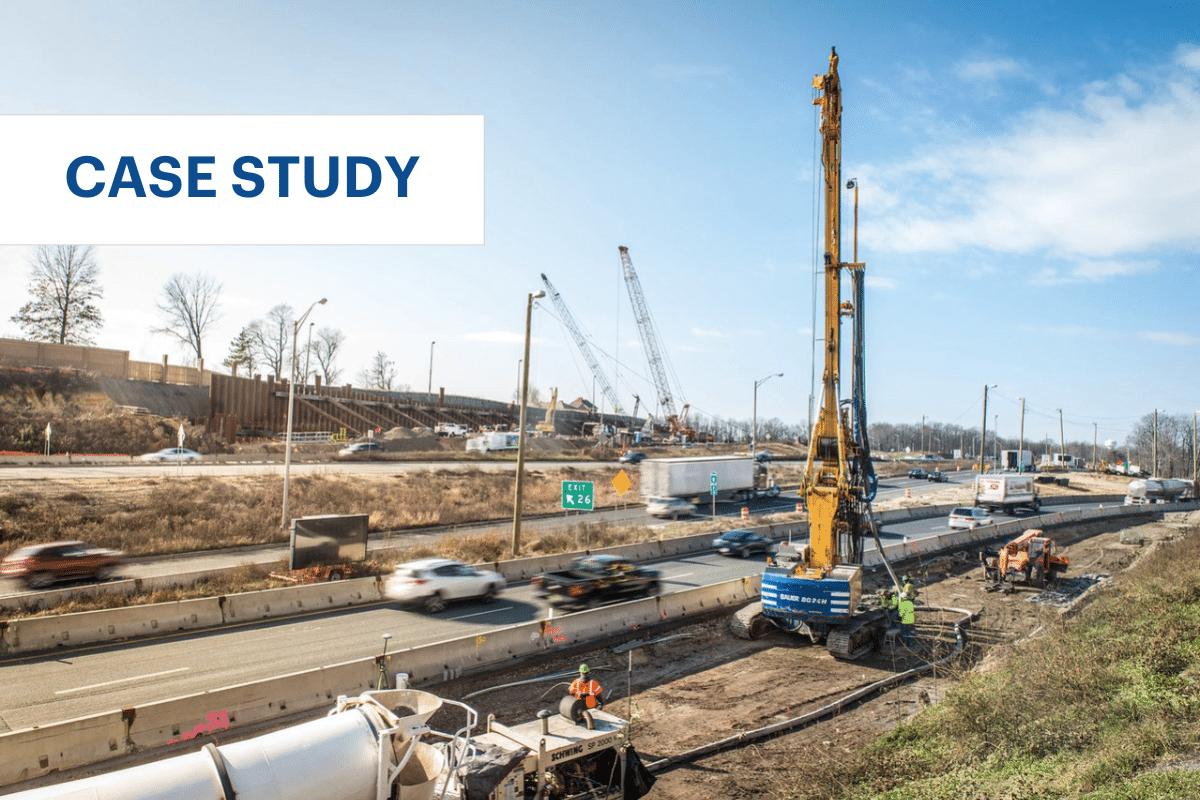

Ground Conditions:

The generalized soil profile revealed 20-50 ft of mine spoil, underlain by alluvial deposits, dense residual soils and shale bedrock. Controlled Modulus Column (CMC)® rigid inclusions were proposed to mitigate the settlement and provide suitable bearing under the proposed structures.

Solution:

To meet the settlement criteria for this project (1″ total and ½” differential), Menard’s design engineers evaluated the performance of 12.5-in and 15.7-in diameter CMCs installed through the mine spoil and alluvium, where present. The CMCs were designed to terminate in either dense residual soils or on shale bedrock.

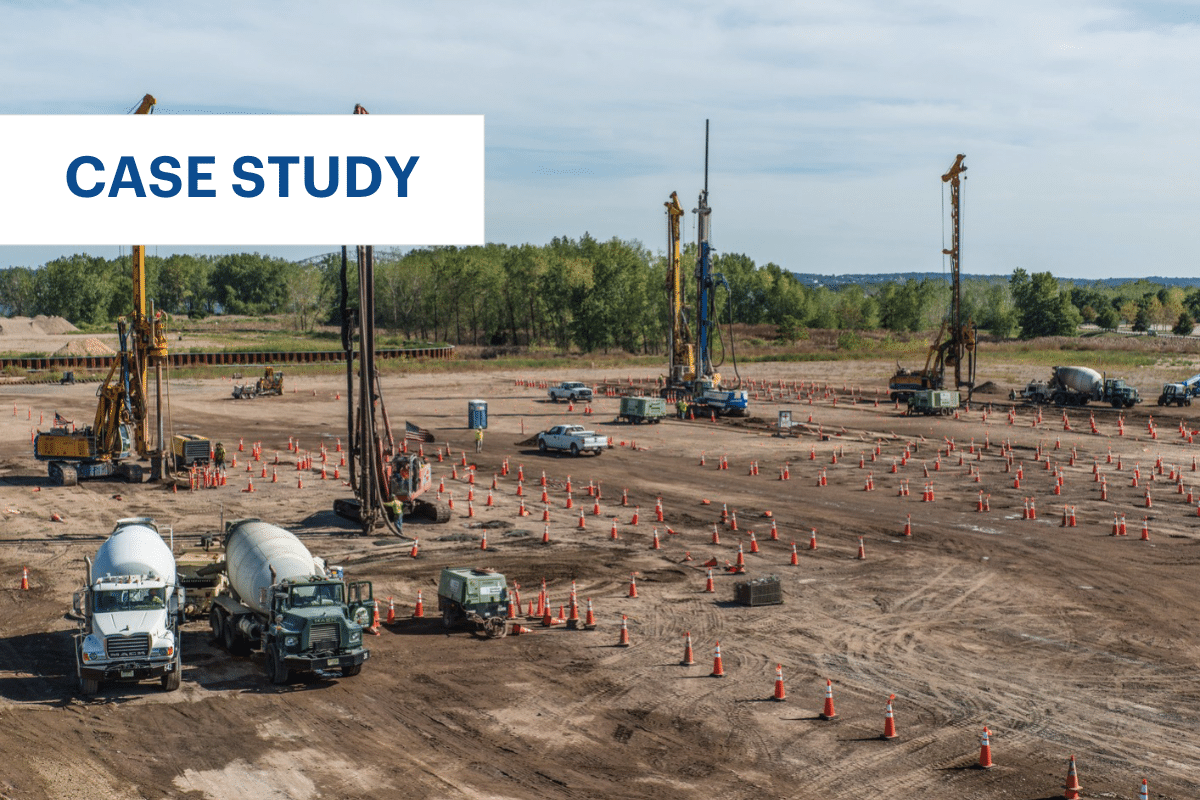

The design, which incorporated 496 CMCs, provided support under spread footings that supported the structures. The average depth of the CMCs was 48.4 ft. and Menard completed the installation of the CMCs within five weeks.

All work was completed in one continuous phase with all quality control testing meeting specified requirements.

Print this resource