Flat Rock Data Center

Flat Rock Data Center

Project Details:

Owner: Confidential Auto Manufacturer

General Contractor: Granger Construction Company

Dates of Work: 09/2017 to 10/2017

Engineer: IBI Group (Structural) and Mannik Smith Group (Geotechnical)

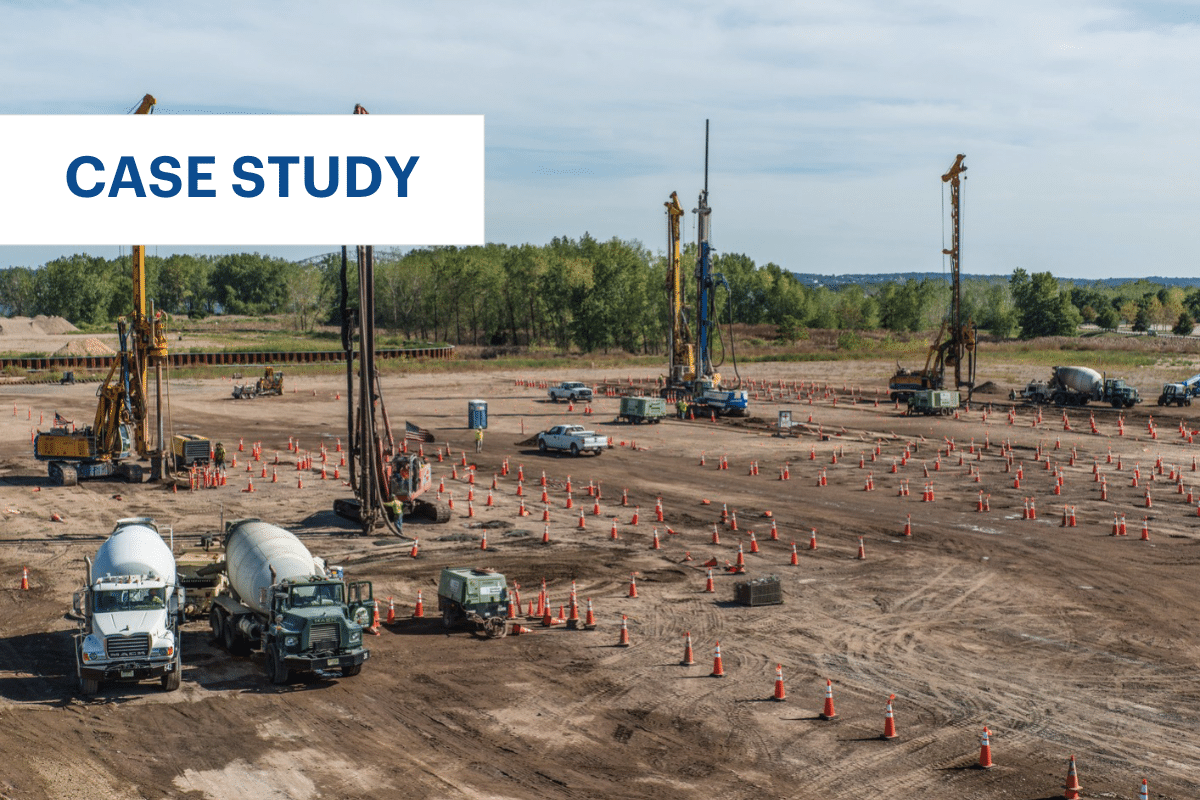

Approximate Key Quantities: Dynamic Replacement 214 EA and Stone Columns 246 EA.

Project Overview:

Ground Conditions:

Solution:

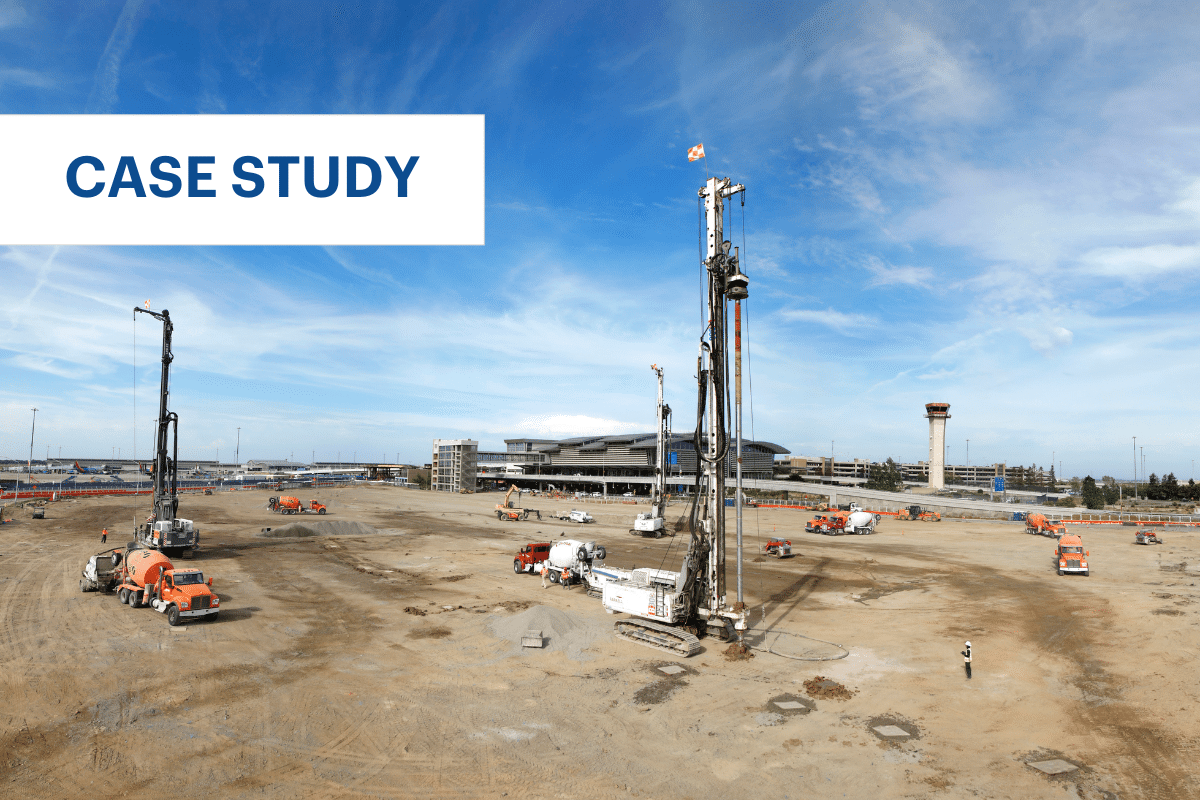

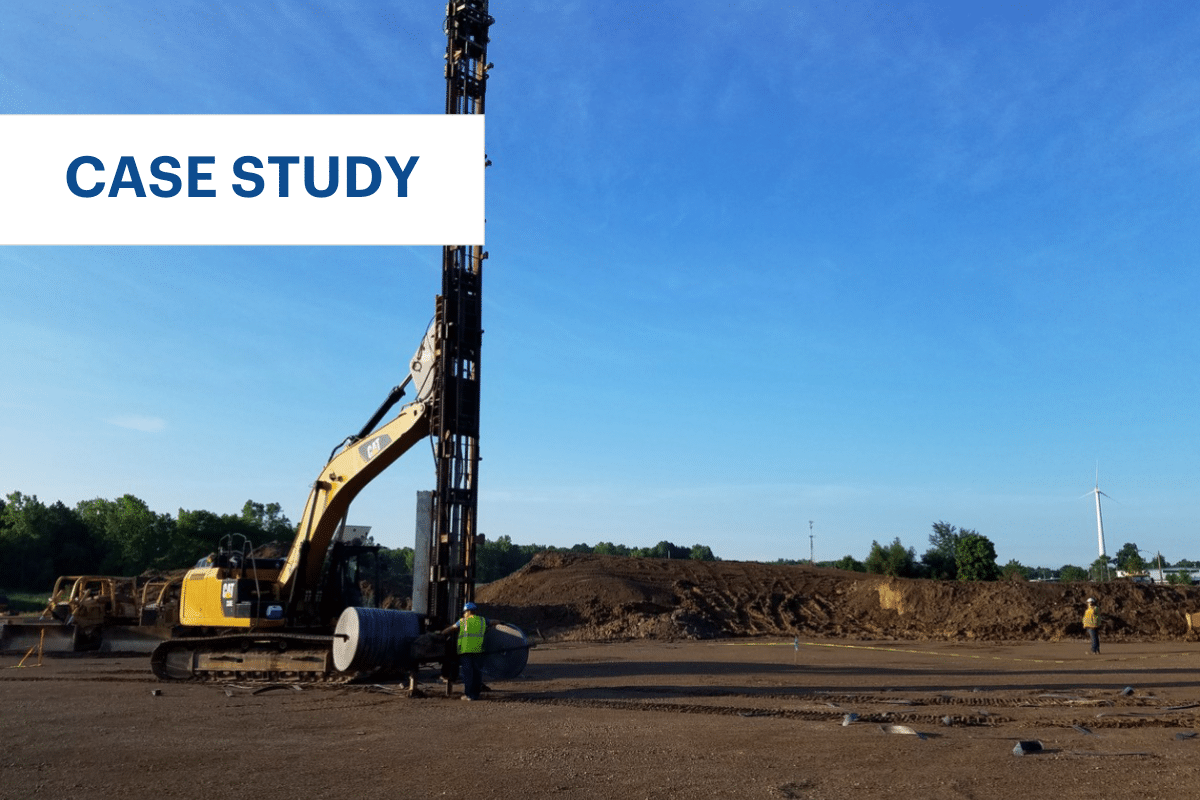

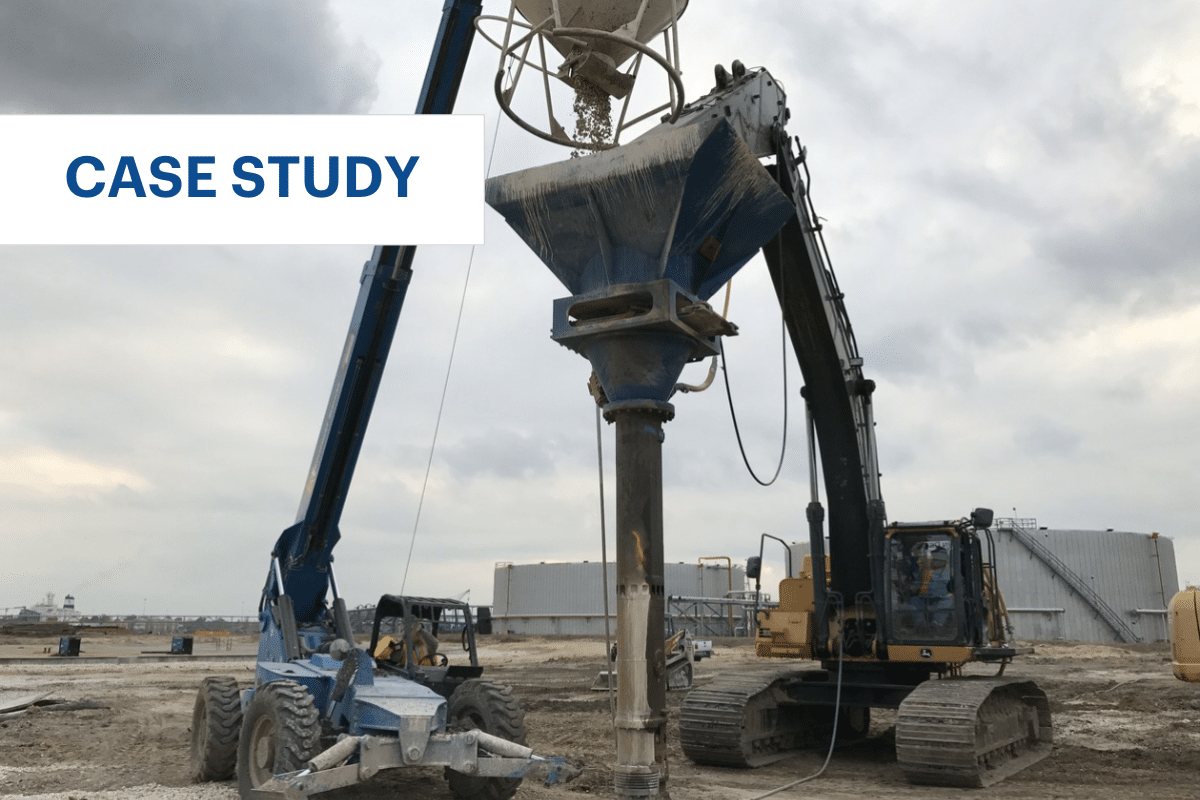

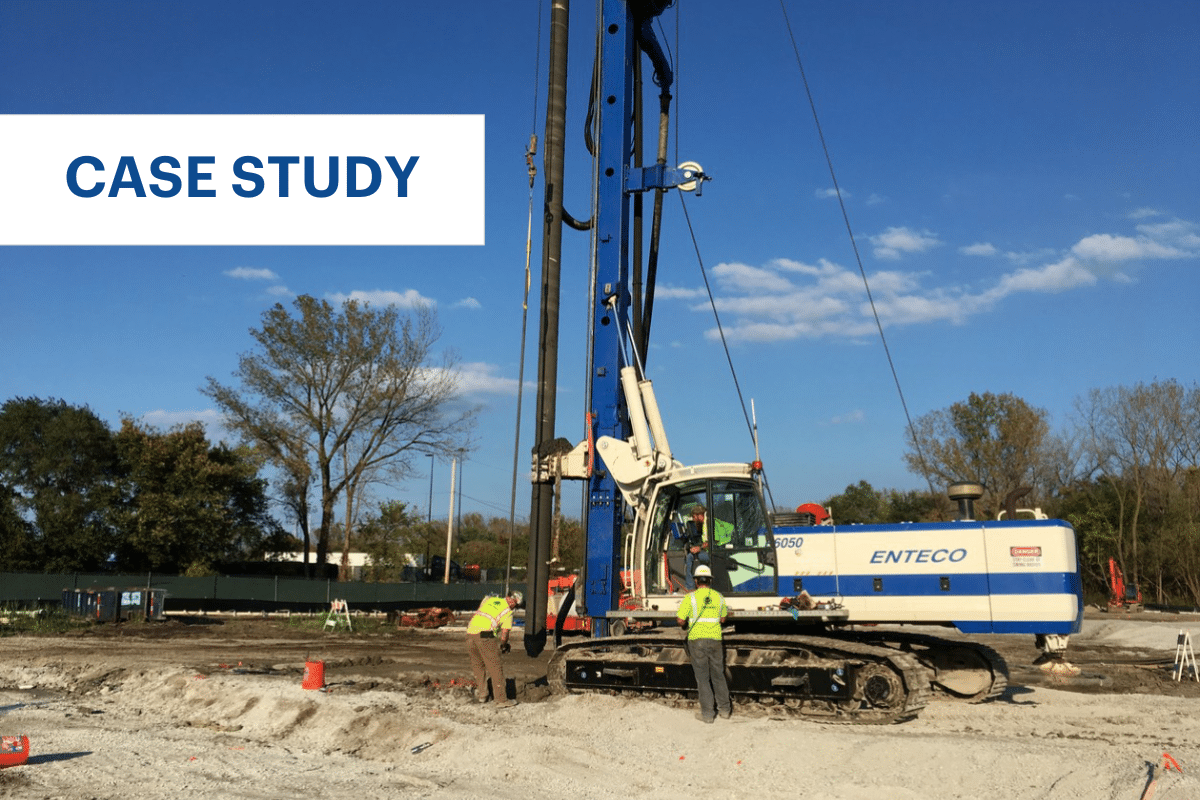

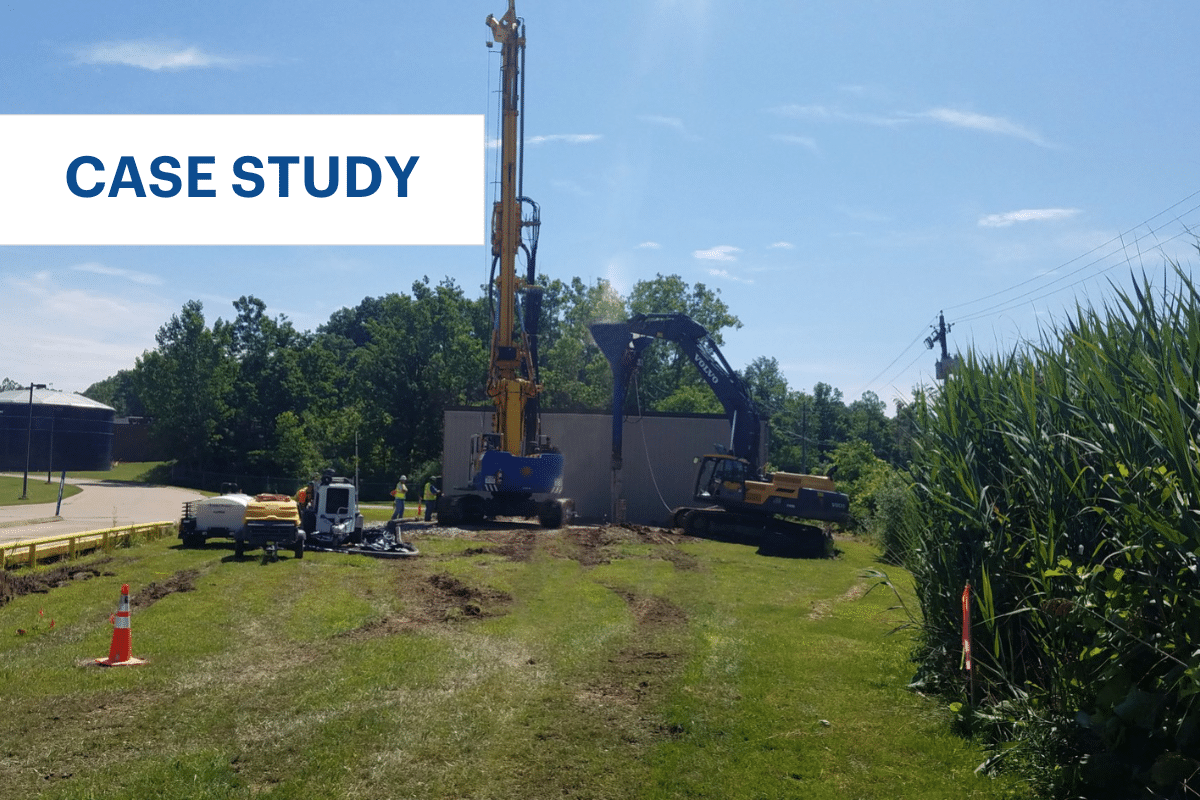

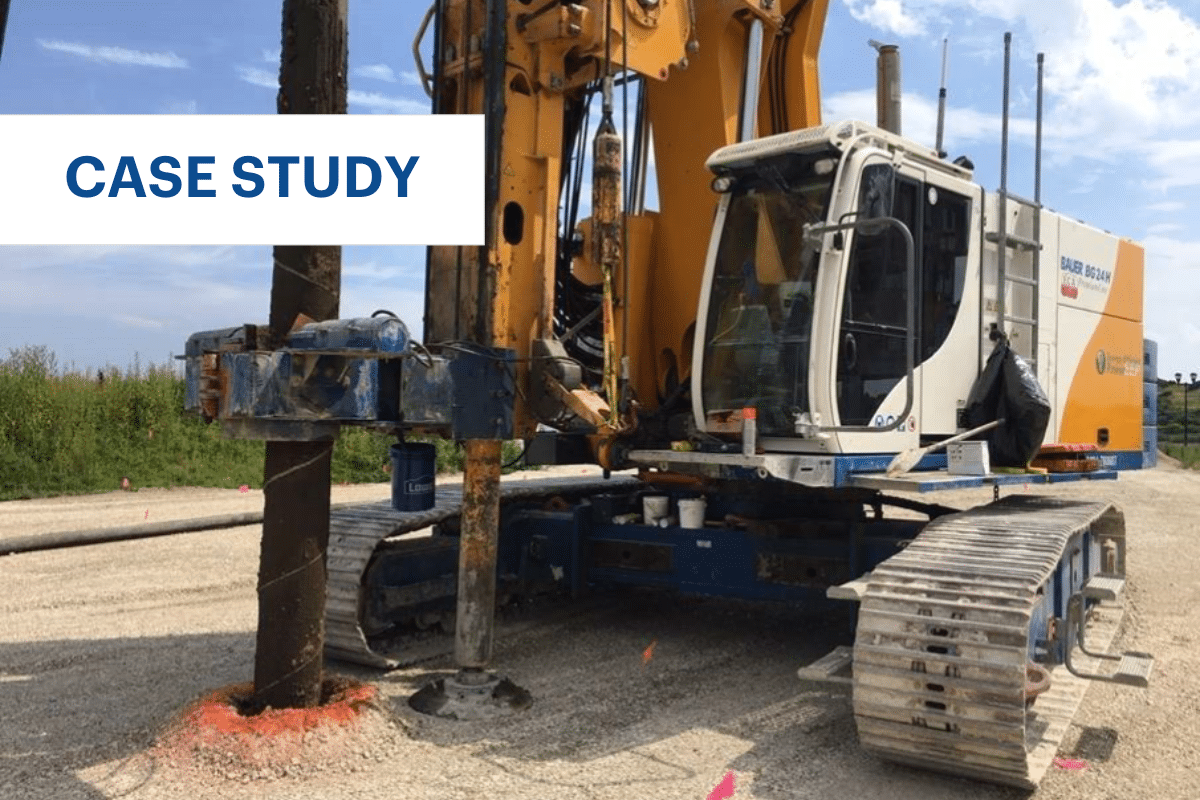

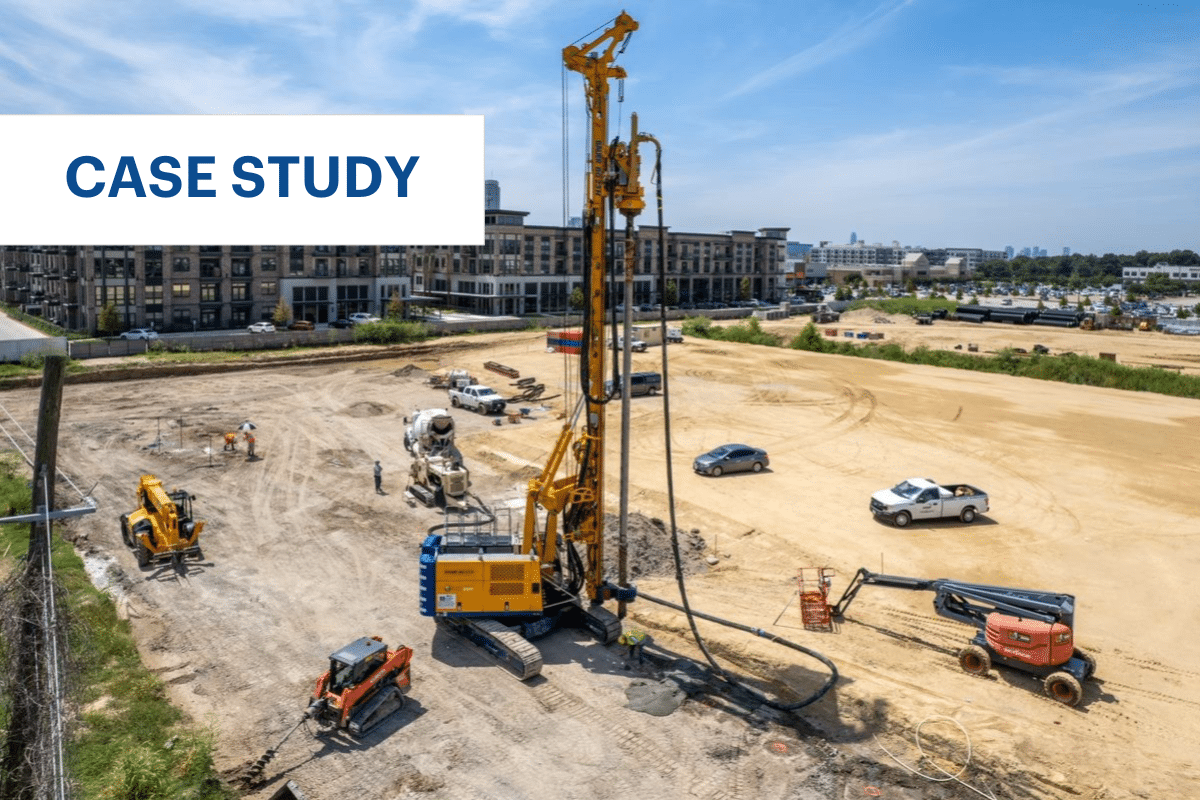

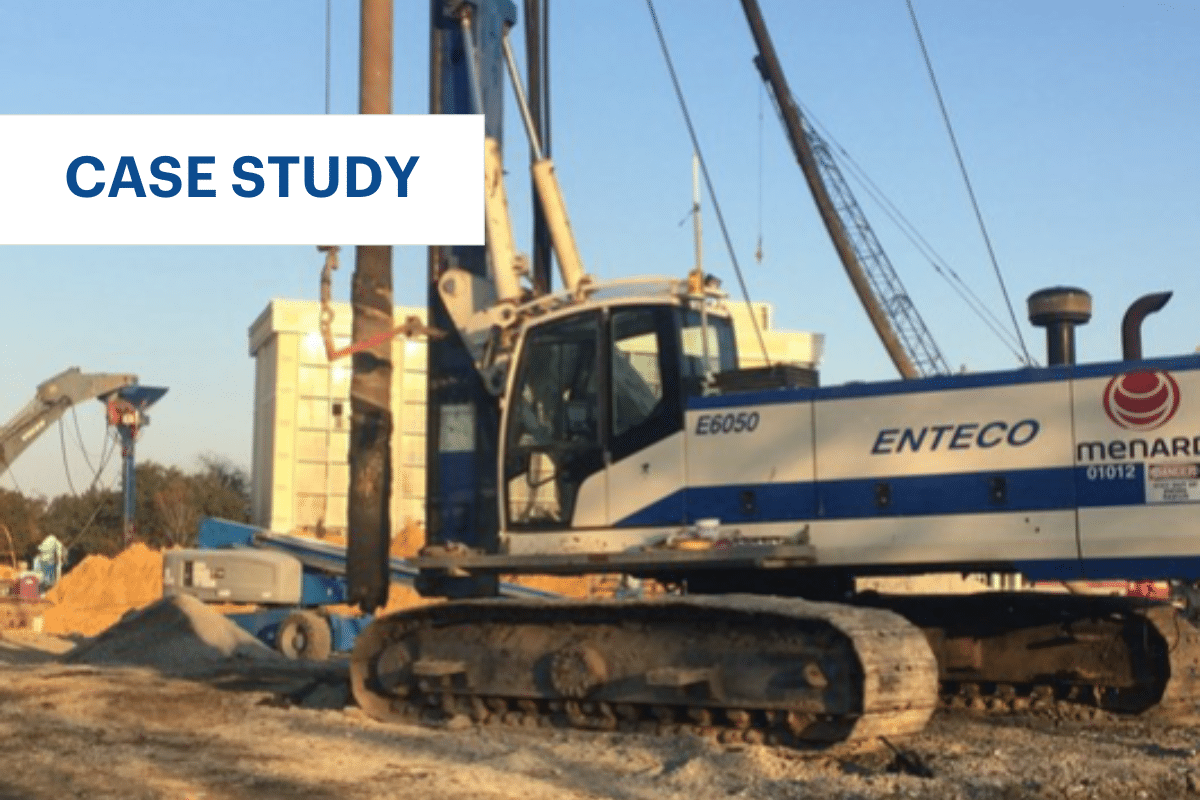

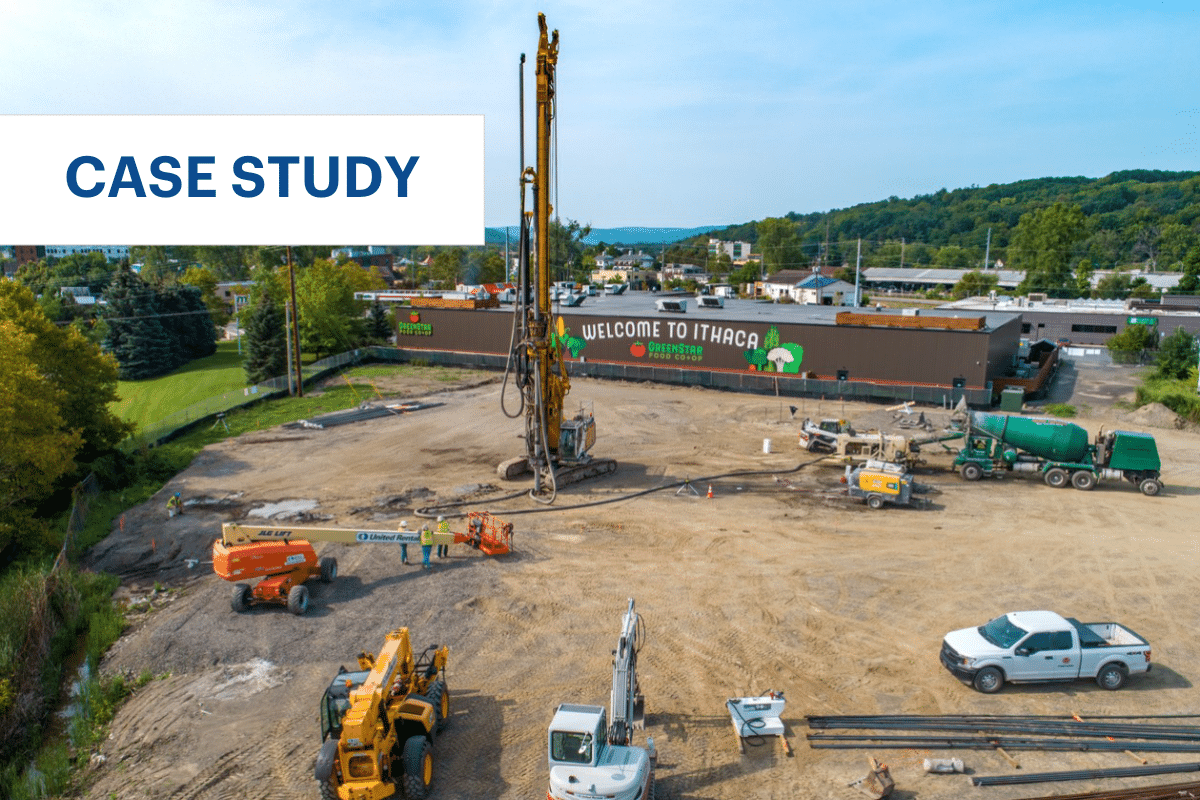

Auger cast piles were originally considered for foundation support. However, Menard provided an economical and time-saving solution with dynamic replacement. This ultimately saved the client $1.5 million. Menard dynamic replacement is used to form granular columns with diameters up to 8 ft and to depths of up to 20 ft. A layer of coarse granular material is installed to provide a working platform and to confine soft surface soil. Dynamic replacement columns are formed by driving the coarse material into the soil with 15- to 30-ton pounders, dropped from heights of 30 to 120 ft. The column is refilled with granular material, which is again compacted. The process repeats until the desired depth and column volume are achieved. These large diameter granular columns (also called inclusions) have a very high modulus of deformation therefore reducing postconstruction settlements.

For this project, dynamic replacement not only provided columns for very high bearing pressure, but also created a densified zone of sand around the building columns for improved slab performance. This was not a requirement of the design, yet provided an additional benefit to the client. Menard’s solution included 214 dynamic replacement columns (5 ft in diameter) installed to a maximum depth of 12 ft for the main building. Menard excavated to loosen the dense upper layers prior to performing the dynamic replacement. To support the two cooling towers, Menard installed 276 VSCs to an average depth of 15 ft and a maximum depth of 19 ft. The design provided for 1 in of post-construction settlement with less than a ½-in of differential settlement, meeting the performance criteria of the data center and cooling towers.

To support a new data center for a confidential client, Menard performed dynamic replacement and allowed the client to eliminate auger cast piles and costly pile caps and grade beams. Stone columns provided an economical solution to support two cooling towers.

Print this resource