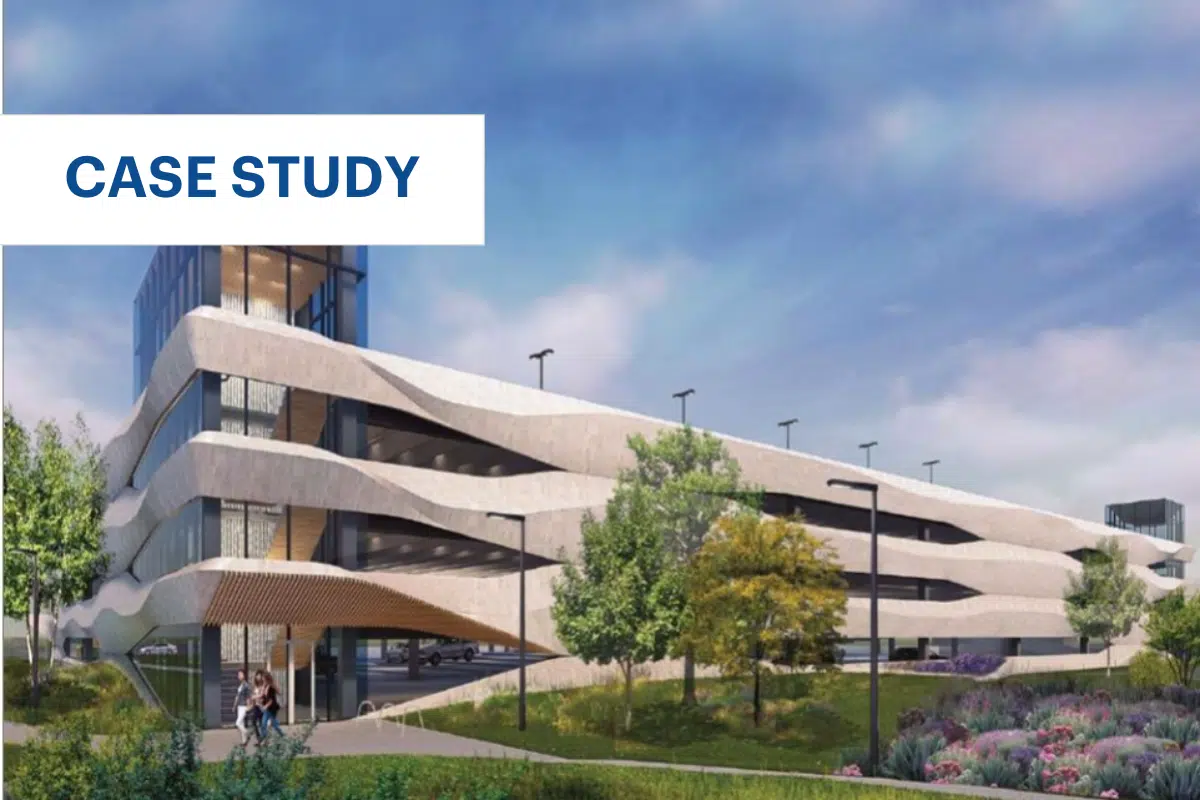

PSU Milton S. Hershey West Garage

PSU Milton S. Hershey West Garage

Project Details:

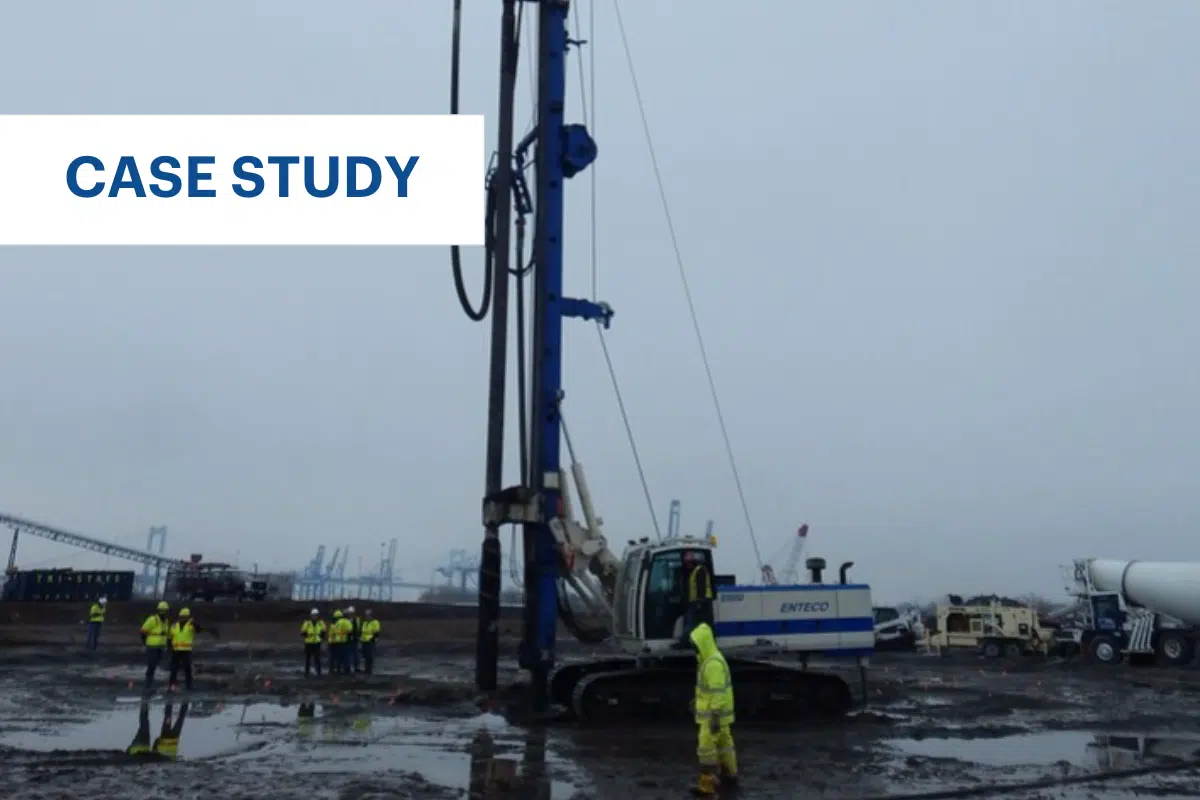

Owner: PSU Milton S. Hershey West Garage

General Contractor: Clayco

Date of Work: December 2018 - May 2019

Engineer: ECS Mid-Atlantic, LLC

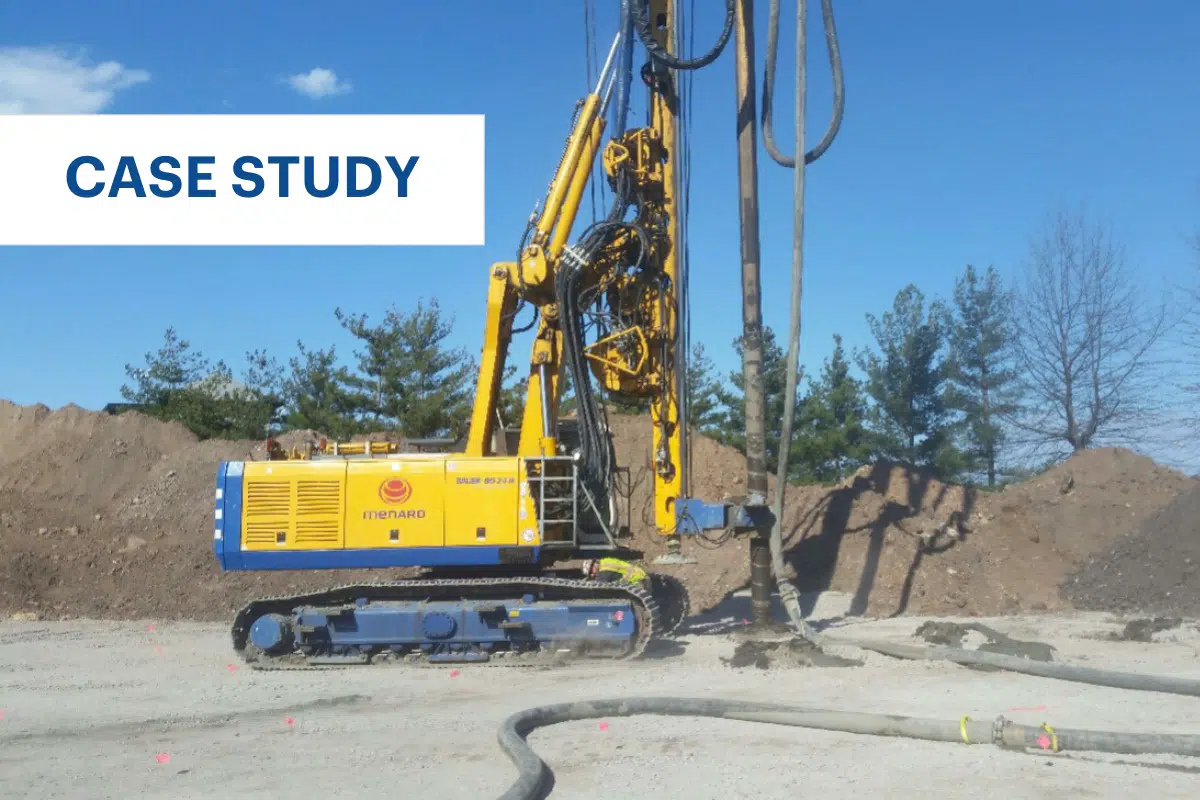

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 560 EA.

Description:

Ground Conditions:

Solution:

Micropiles were initially proposed for the project but were determined to be prohibitively costly with an extensive schedule. Menard proposed a hybrid solution, which included rock grouting the top 5 ft of bedrock beneath the footings and wall foundations and shallow Controlled Modulus Column (CMC)® rigid inclusion treatment of the fills and clayey sand above the bedrock. The combination of compaction grouting and CMC rigid inclusions delivered significant cost savings as compared to the original micropile scheme which would have required pile caps and grade beams. The compaction grouting and CMC rigid inclusion approach allowed for the use of spread footings and strip footings.

Menard installed approximately 560 CMC rigid inclusions to an average depth of 24 ft and maximum depth of 45 ft. Despite challenging winter weather conditions and delays related to the relocation of existing utilities, Menard completed work in eight weeks.

To support the construction of a five- story parking garage (with the capacity to expand to seven stories) on the Penn State Milton S. Hershey Medical Center campus, Menard USA installed 560 rigid inclusions, in addition to implementing Compaction Grouting to improve the overlying poor soils. Menard’s hybrid solution provided a less costly alternative than the originally proposed micropiles which would have required pile caps and grade beams.

Print this resource