Liverpool Wastewater Treatment Plant

Liverpool Wastewater Treatment Plant

Project Details:

Owner: Medina County Sanitary Engineers

General Contractor: Overland Contracting (Black & Veatch)

Date of Work: January 2017 - December 2017

Engineer: Timmerman Geotechnical Group, Inc.

Approximate Key Quantities: Bi-Modulus Columns (BMC)® - 263 EA.

Description:

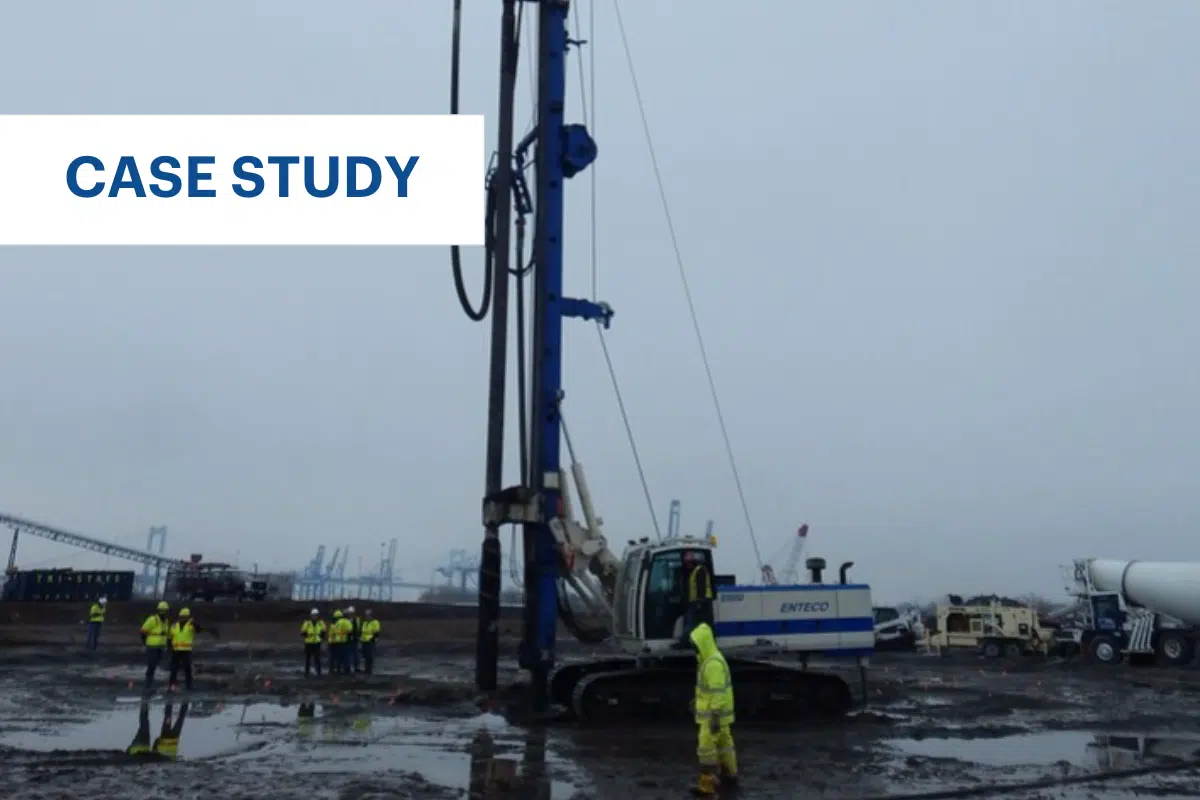

The Liverpool Wastewater Treatment Plant (WWTP), located about 30 miles south of Cleveland in Medina, OH, was the proposed site for the construction of three new tanks as part of a facility-wide upgrade. The resulting plant will be self-sustaining by using a blend of renewable biogas and natural gas to power its operation (www.bv.com).

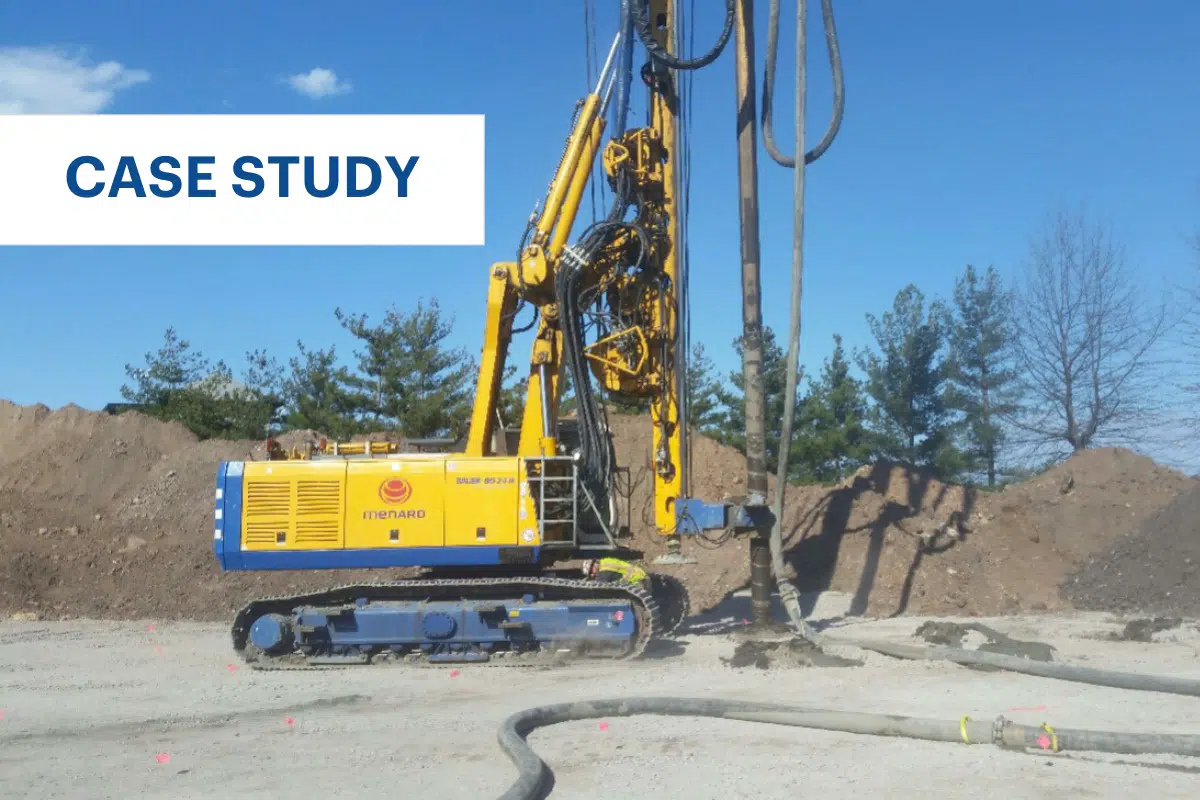

The three tanks, one with a 20-ft diameter and the other two with 64-ft diameters, are part of an anaerobic digestion process which breaks down organic matter into biogas to be used in generating power. Menard designed and installed Bi-Modulus Columns (BMC)ᵀᴹ to improve bearing capacity, control settlement, and to allow for easier excavation of the cone-down tank bottoms.

Ground Conditions:

Solution:

The anaerobic digestion process produces considerable quantities of methane and other volatile gases. Due to the presence of these flammable substances, Menard crews were required to pass specialized safety training including wearing monitors to measure the amount of gases in the air.

The soft working platform also made it challenging for Menard rigs to move around the working pad and slowed installation. The addition of steel plates and extra stone helped Menard crews stabilize the ground for the equipment so that it could move across the working pad in a safe manner.

A total of 263 BMCs were installed to a maximum depth of 45 ft. When the upgrades are complete, the Liverpool WWTP will save an anticipated $1.5 million annually in operations expenditures (www.bv.com).

Print this resource