Eco-Energy Ethanol Terminal

Eco-Energy Ethanol Terminal

Project Details:

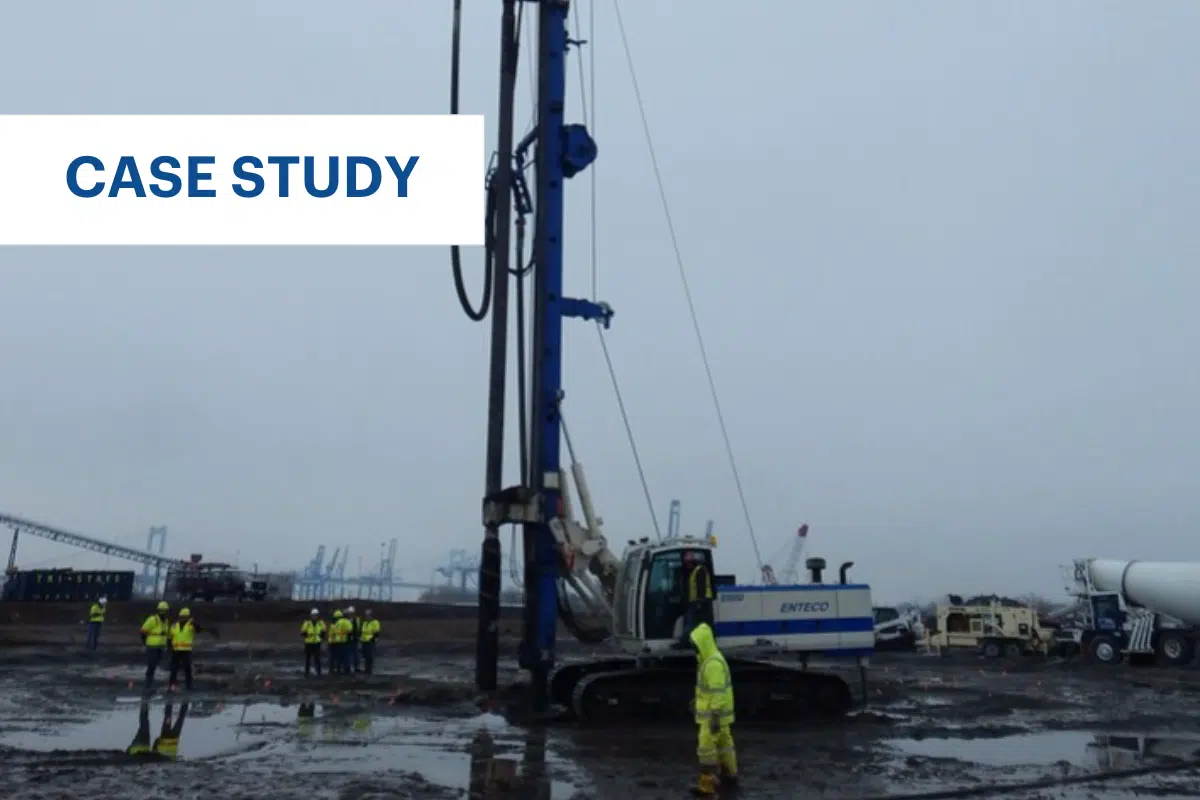

Owner: Eco-Energy Inc.

General Contractor: JPC Group

Date of Work: February 2015 - April 2015

Engineer: GEI Consultants, Inc.

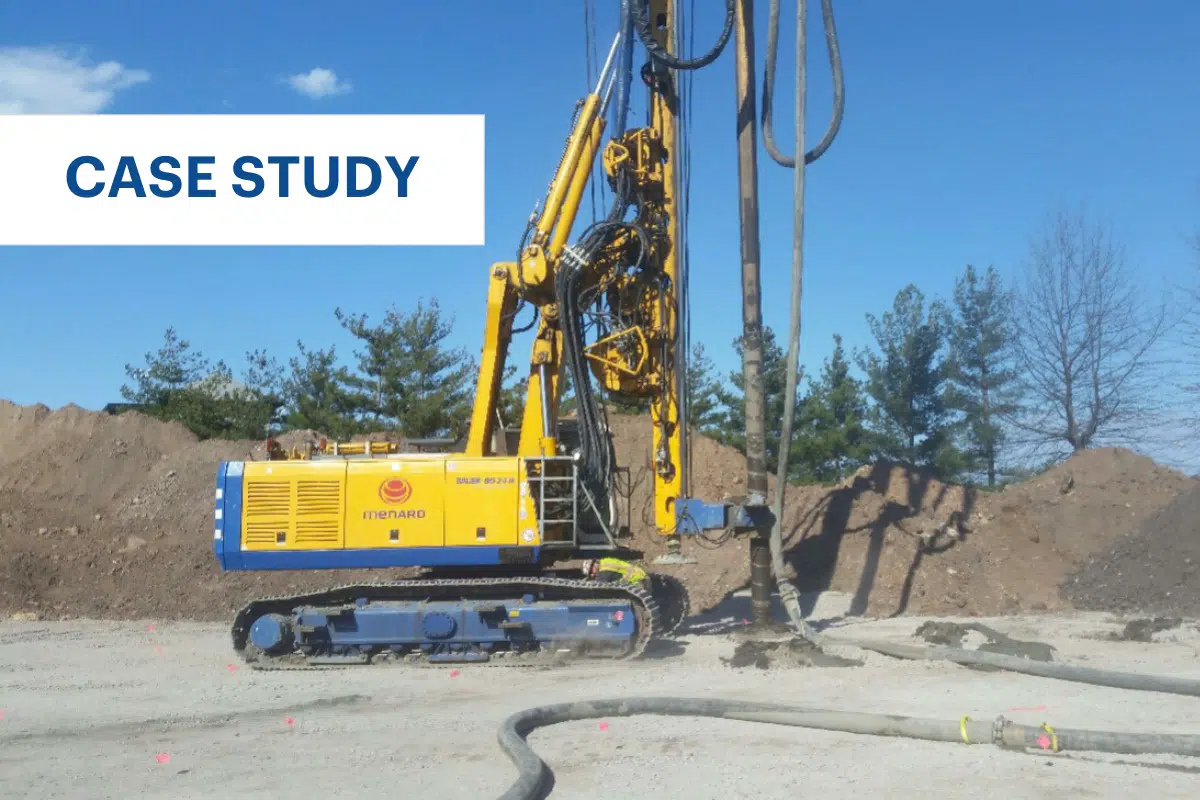

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 573 EA.

Description:

Ground Conditions:

Solution:

To meet the settlement criteria, Menard’s design engineers evaluated the performance of CMCs arranged in a circular pattern for support of the tanks. The CMCs were installed through the soft alluvial silts and clays and terminated in the lower dense gravel.

The design provided support under the entire footprint of the tanks, including the designed ringwall systems. Menard installed 573 CMCs at an average depth of 64 ft to meet the settlement criteria under the two tanks.

Installation was complete within two months of mobilization, meeting the client's requirements for safety, quality and schedule.

Print this resource