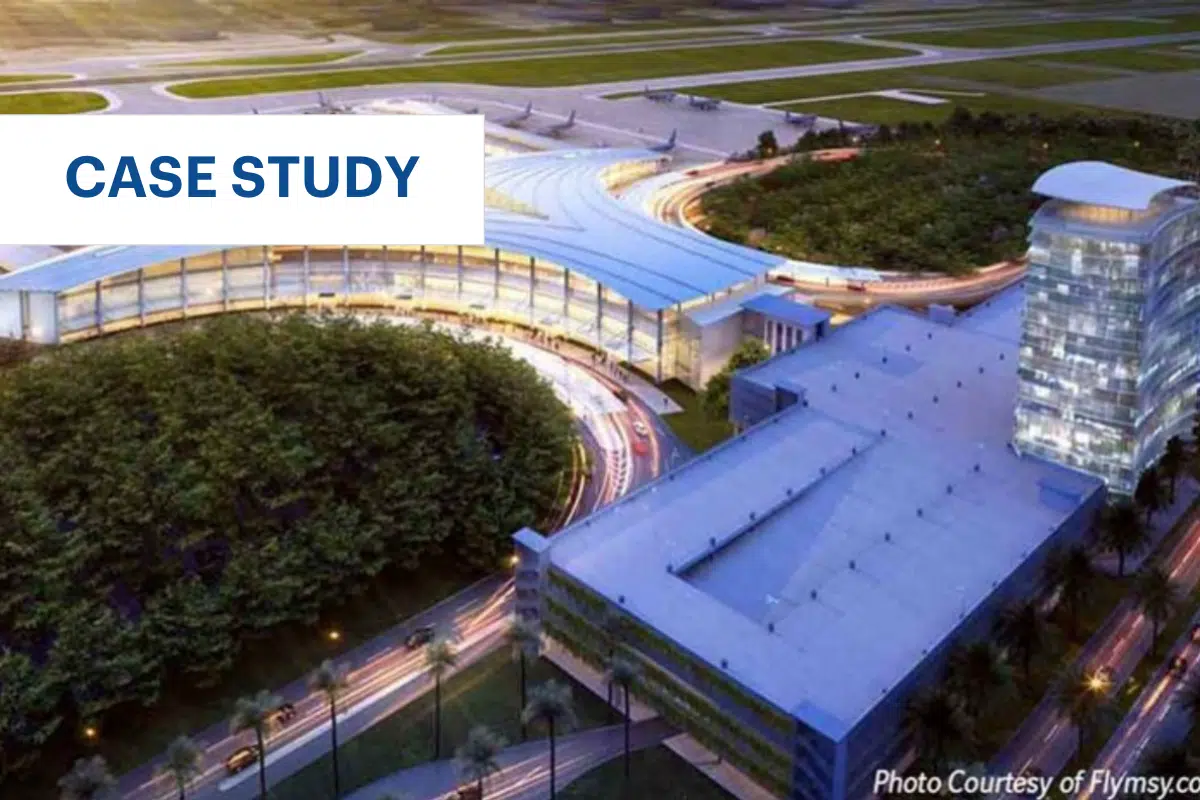

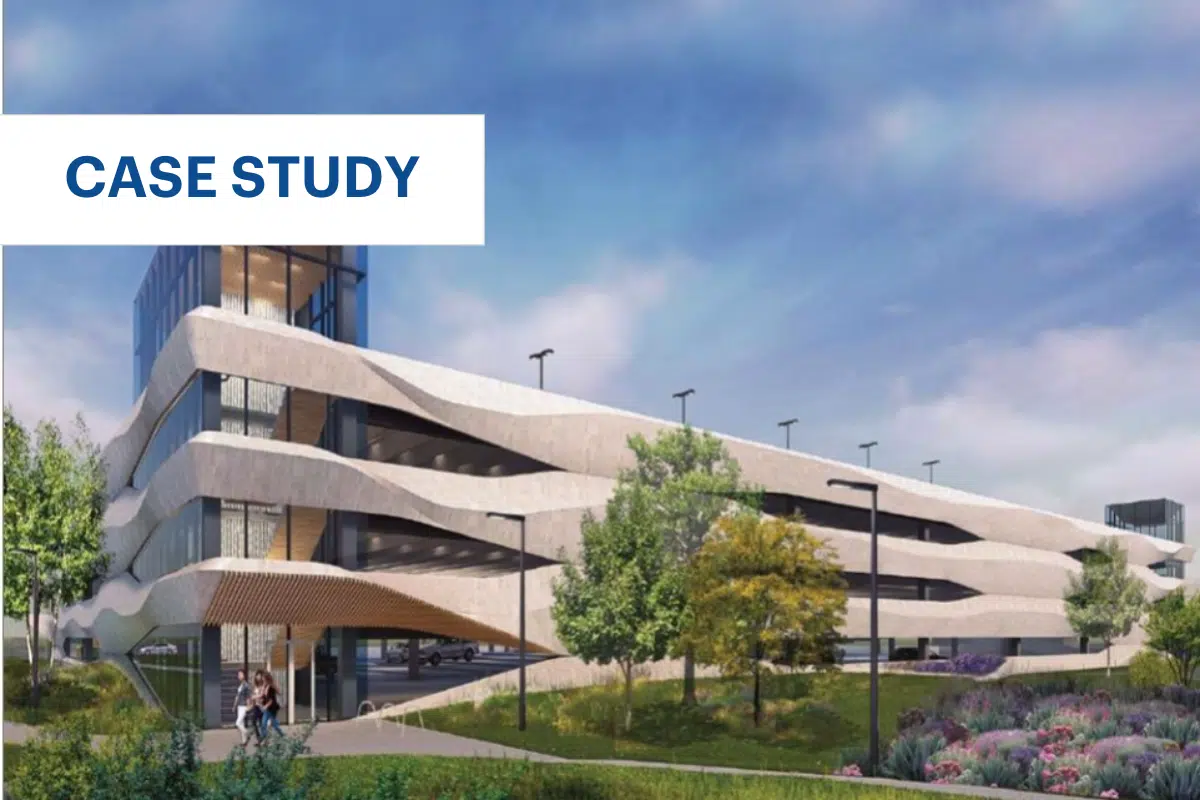

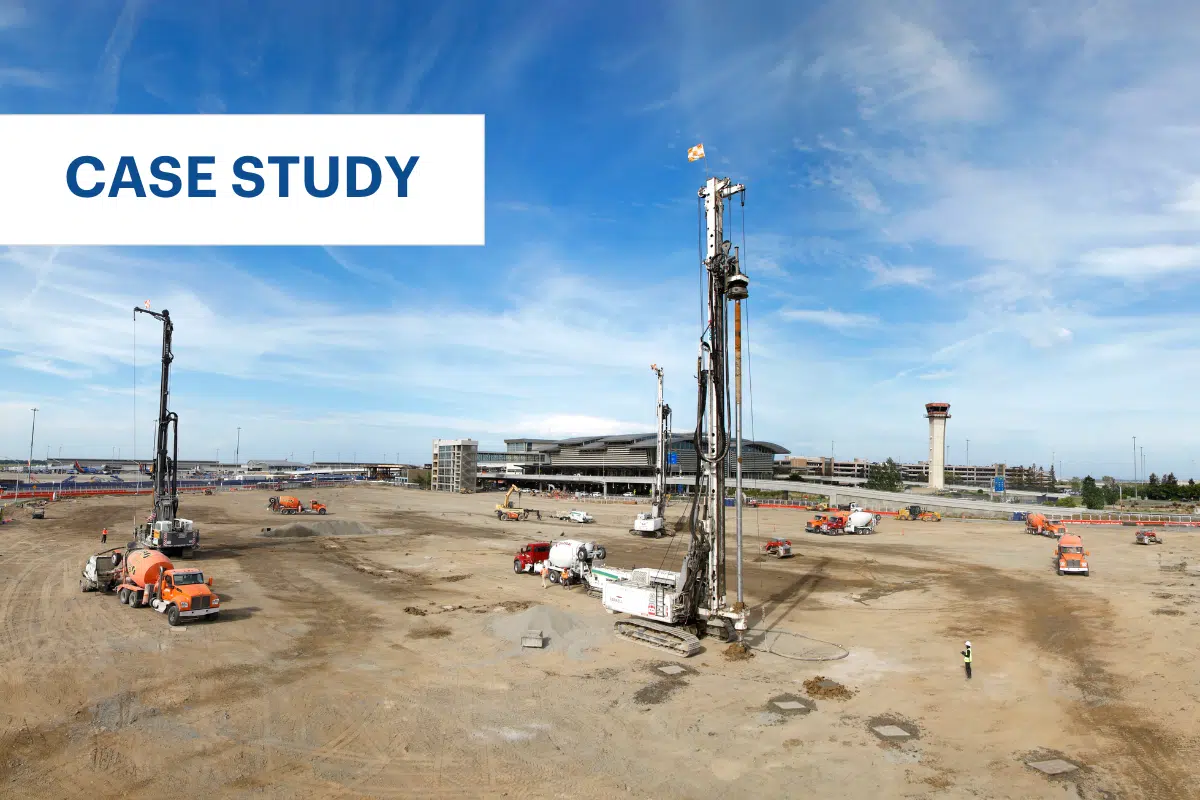

Sacramento International Airport Terminal B Parking Structure

Project Details:

Owner: Sacramento County

General Contractor: Otto Construction - Sacramento, CA

Date of Work: March - April, 2025

Engineer: International Parking Design, Inc.

Approximate Key Quantities: Ductile Rigid Inclusions™

Bearing Support

Uplift Support

Description:

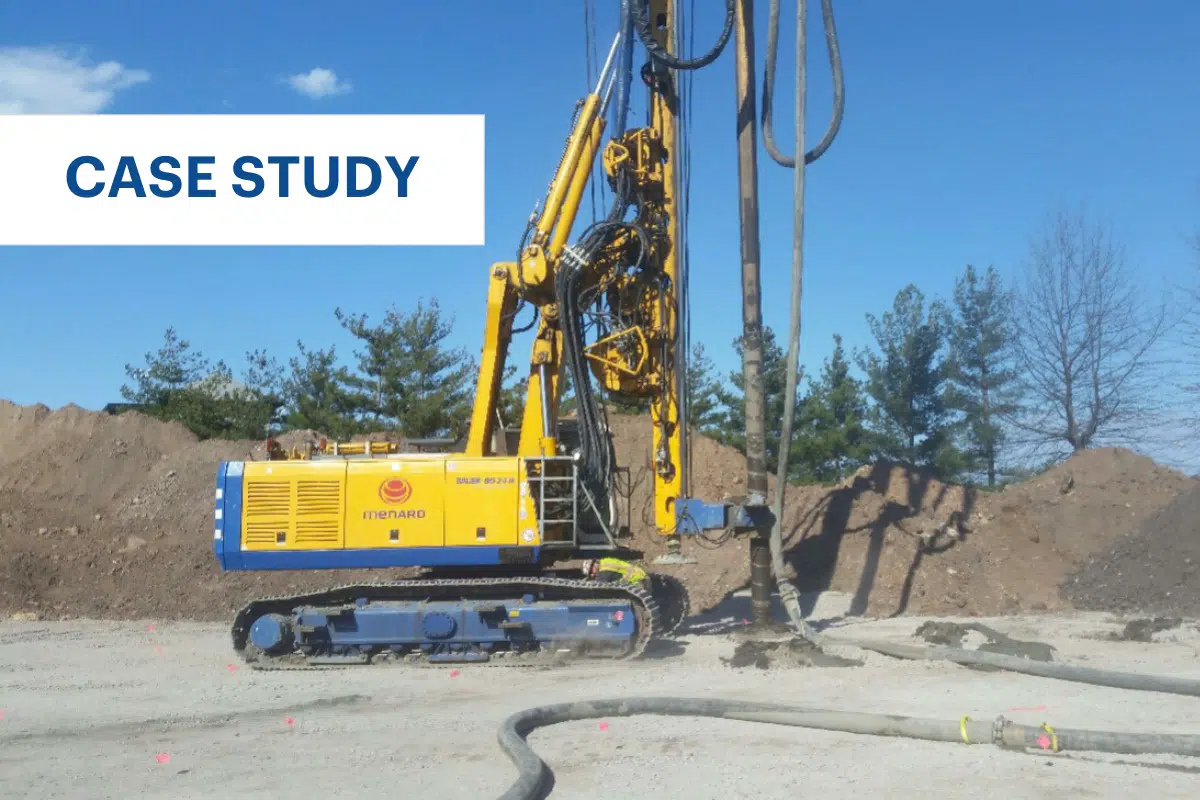

As part of the $1.3 billion SMForward initiative, the Sacramento International Airport Terminal B parking garage is a vital new facility designed to enhance passenger experience and meet rising travel demand from California’s state capital. Spanning 17 acres, the $390 million, six-story garage will provide over 5,500 parking spaces and is expected to open in late 2026. In addition to standard parking, the structure is designed to include EV charging stations, solar panels, and integrated public art on the exterior’s perforated steel panels. The garage replaces a 700-space surface lot and currently occupies a site that includes a Compressed Natural Gas (CNG) fueling station, parking administration building, and canopy structure. Farrell Design-Build (Menard) partnered with Otto Construction and geotechnical engineer Langan to deliver a modern, sustainable foundation solution tailored to the Terminal B parking structure’s complex site conditions.

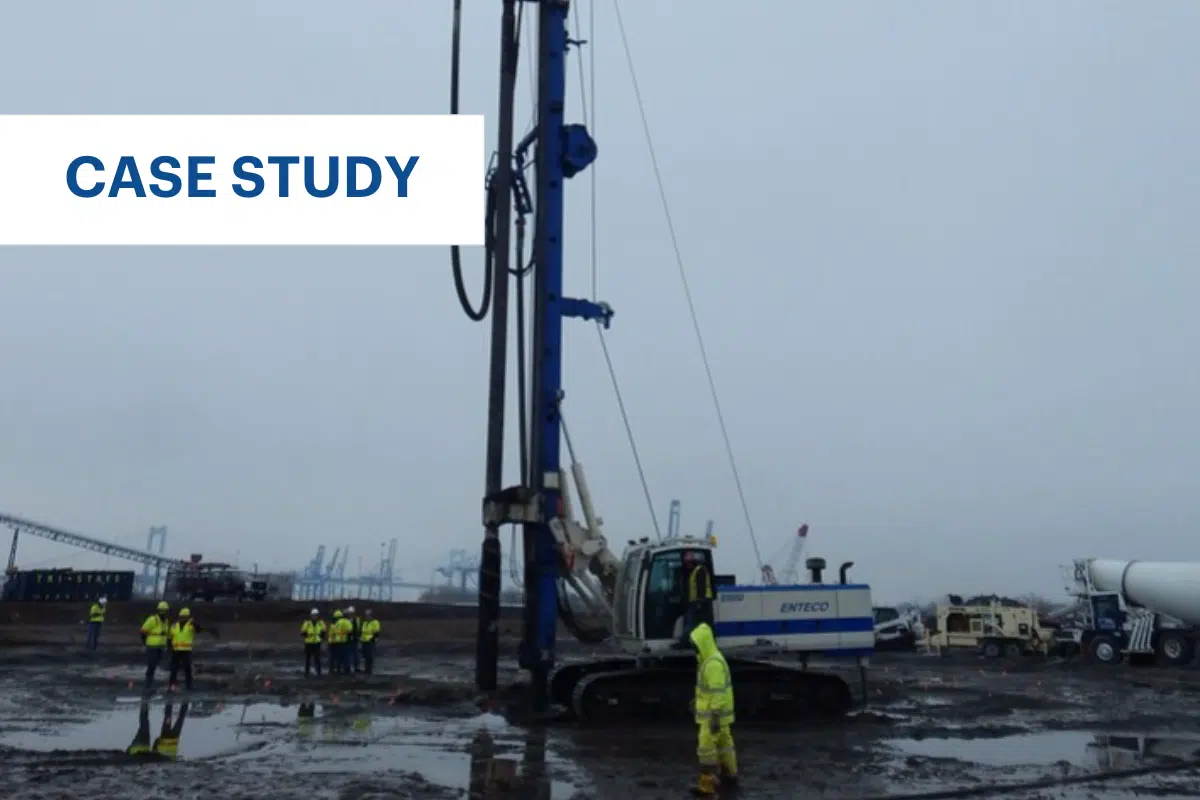

Ground Conditions:

The garage site is located about 2,500 feet east of the Sacramento River. Subsurface investigations revealed variable alluvial soil deposits and undocumented fill. The soil profile includes up to 9 feet of undocumented fill with construction debris that is underlain by loose sands, compressible medium clay, and stiff to hard clays and silts extending to depths of 100 feet. Groundwater was encountered at depths of 9 to 15 feet with a historic design depth of 5 feet. These conditions posed liquefaction and static settlement risks that required a foundation solution tailored to the site's complex soil profile and heavy structural demands.

Solution:

To meet the demands of the six-story parking structure, Farrell Design-Build installed thousands of Ductile Rigid Inclusions™ (DRI)—also known as Fiber-Reinforced Rigid Inclusions™ (FRRI). The DRI system combines the displacement efficiency of rigid inclusions with the added resilience and ductility of fiber reinforcement, providing a robust, high-performance ground improvement solution. Farrell’s design-build approach was selected to mitigate seismic and static settlement in the undocumented fill and loose sands, and to transfer loads efficiently to the deeper competent soils. Ground anchors were incorporated at specific foundation locations to provide uplift resistance against vertical seismic loads in lieu of oversized foundation. Farrell’s team carefully tailored the layout and depth of the DRI elements to address both structural loading (bearing and uplift) and geotechnical challenges across the site, delivering a foundation solution that not only met performance requirements, but also elevated the project’s sustainability and efficiency goals.

Print this resource