Glasshouse in Station Square

Project Details:

Owner: Trammell Crow Company

General Contractor: Rycon Construction, Inc.

Duration of Work: 8 weeks

Subsurface Conditions: Mainly granular random fill and alluvial soils sitting atop of sedimentary bedrock with a mix of sand, silt, gravel, slag, rock and brick fragments.

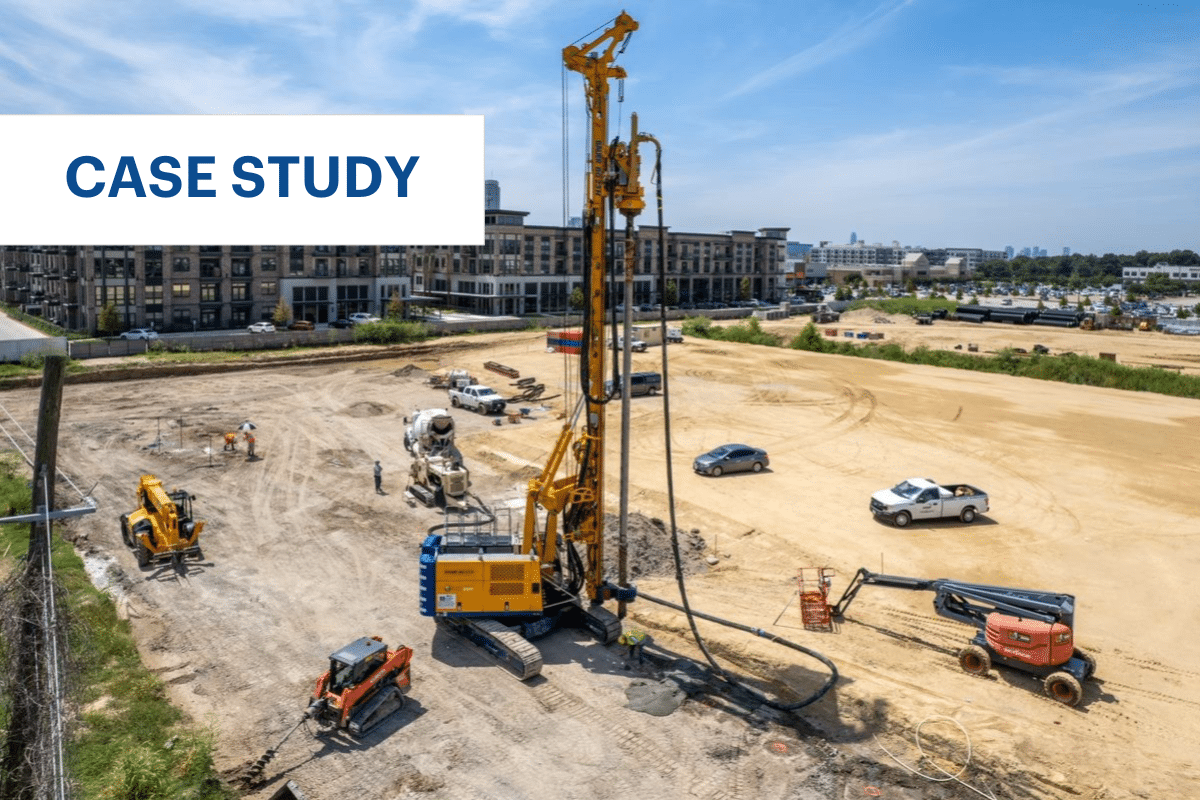

Approximate Key Quantities: 697 stone columns

Project Overview:

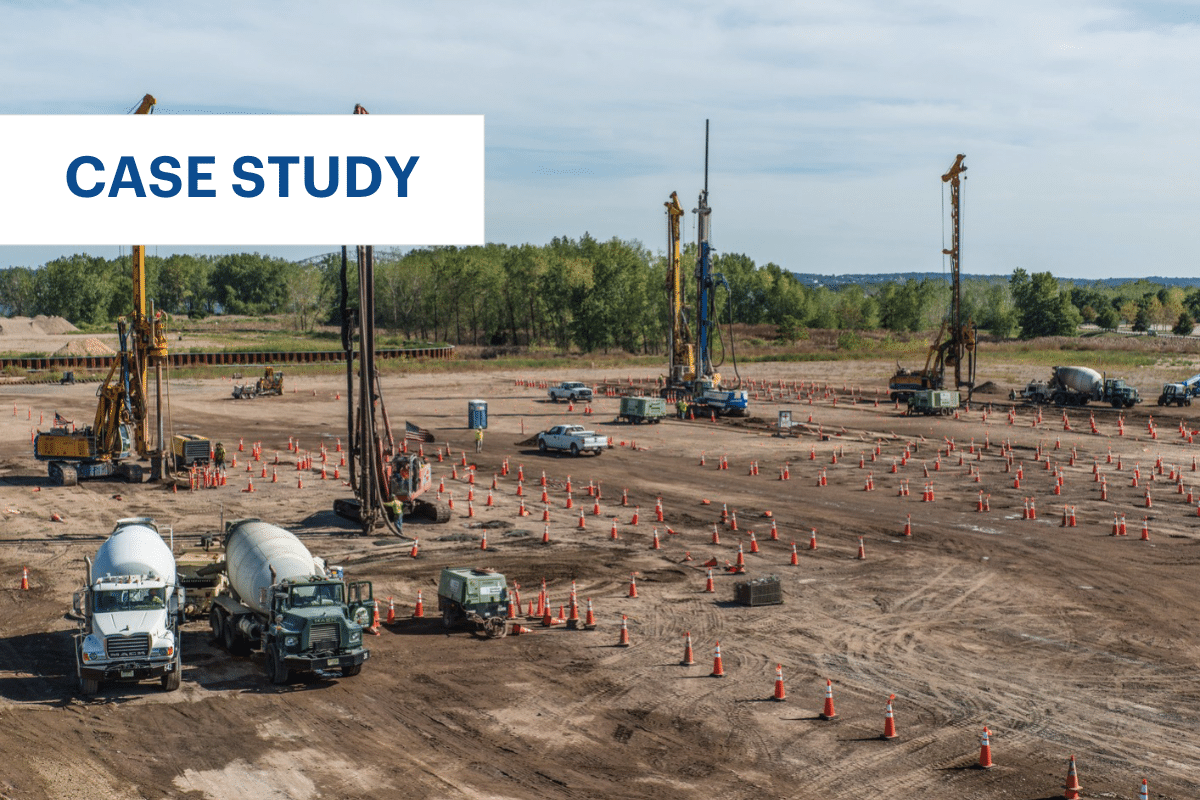

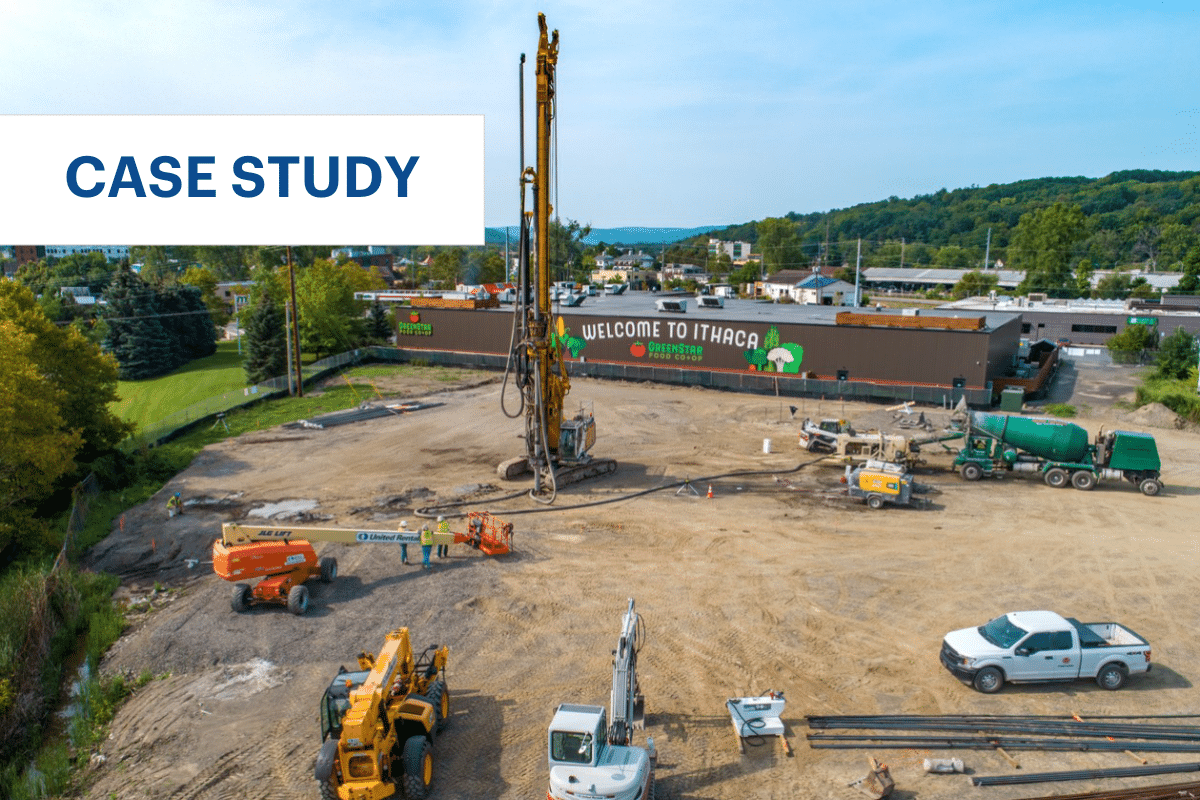

As an ode to Pittsburgh’s past, a proposed development in Station Square was termed Glasshouse, a reference to the city’s days as the nation’s top glass producer in the 1920s. The project would involve the construction of two new, four-story mixed-use buildings with associated courtyards, and a below grade parking garage. The project site, off of East Carson Street near the Smithfield Bridge, was once the home of the East Warehouse building. Its original function was a transfer and storage area for the railroad industry then later occupied by restaurants and nightclubs before its demolition.

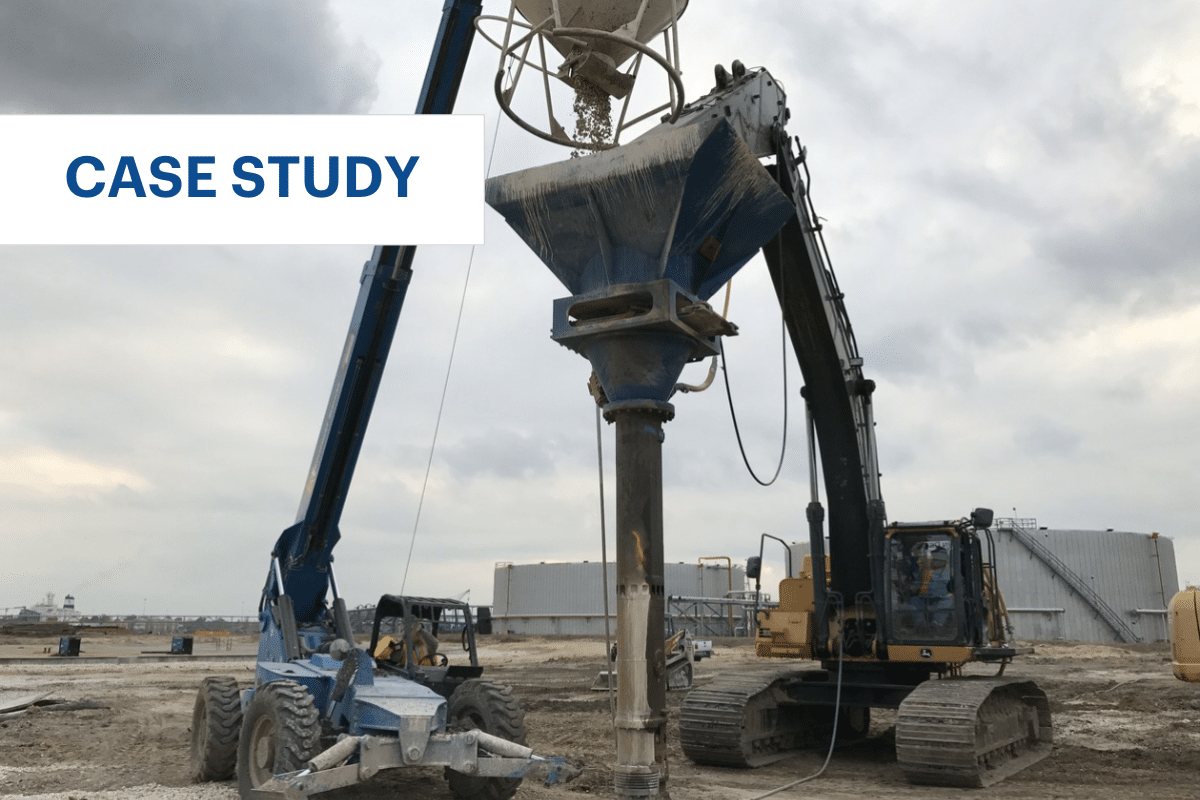

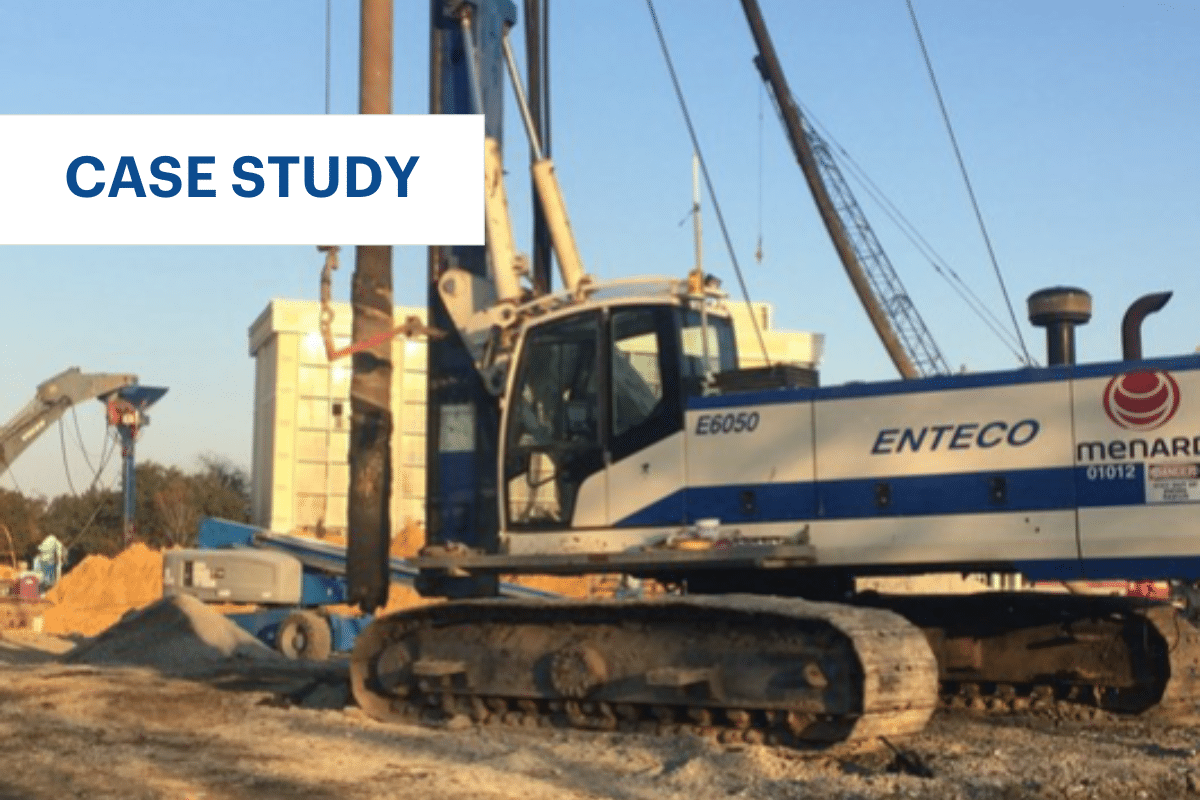

Due to the compressible nature of the soils at the site, Menard USA proposed the use of Stone Column (SC) ground improvement beneath the spread footings and strip footings at the parking level to support the structure and courtyard areas.

Ground Conditions:

The ground mainly consisted of random fill and alluvial soils sitting atop of sedimentary bedrock. The fill was mainly granular with a mix of sand, silt, gravel, slag, with rock and brick fragments. The fill ranged in thickness from 16.5 ft to 36.5 ft. The alluvial soil thickness varied between 27 ft and 38 ft. The main components of the alluvial layers were sand, silt, gravel and localized pockets of clay.

Solution:

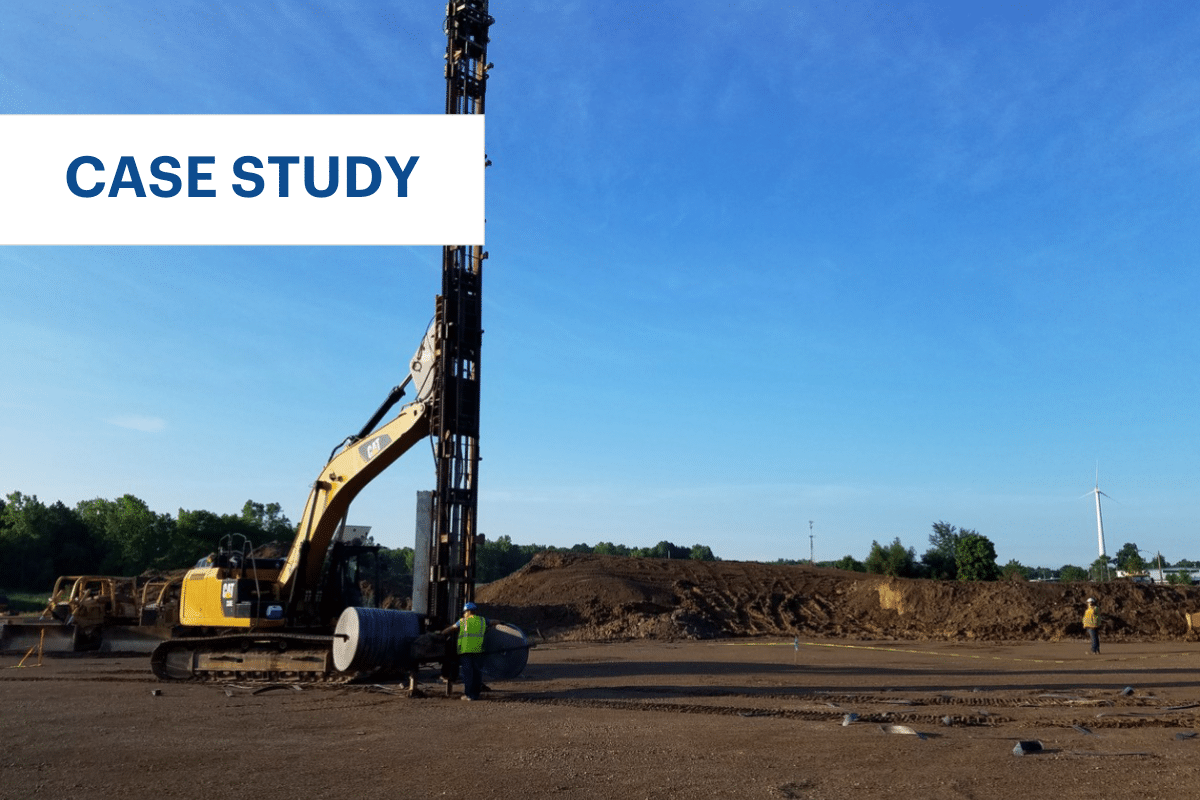

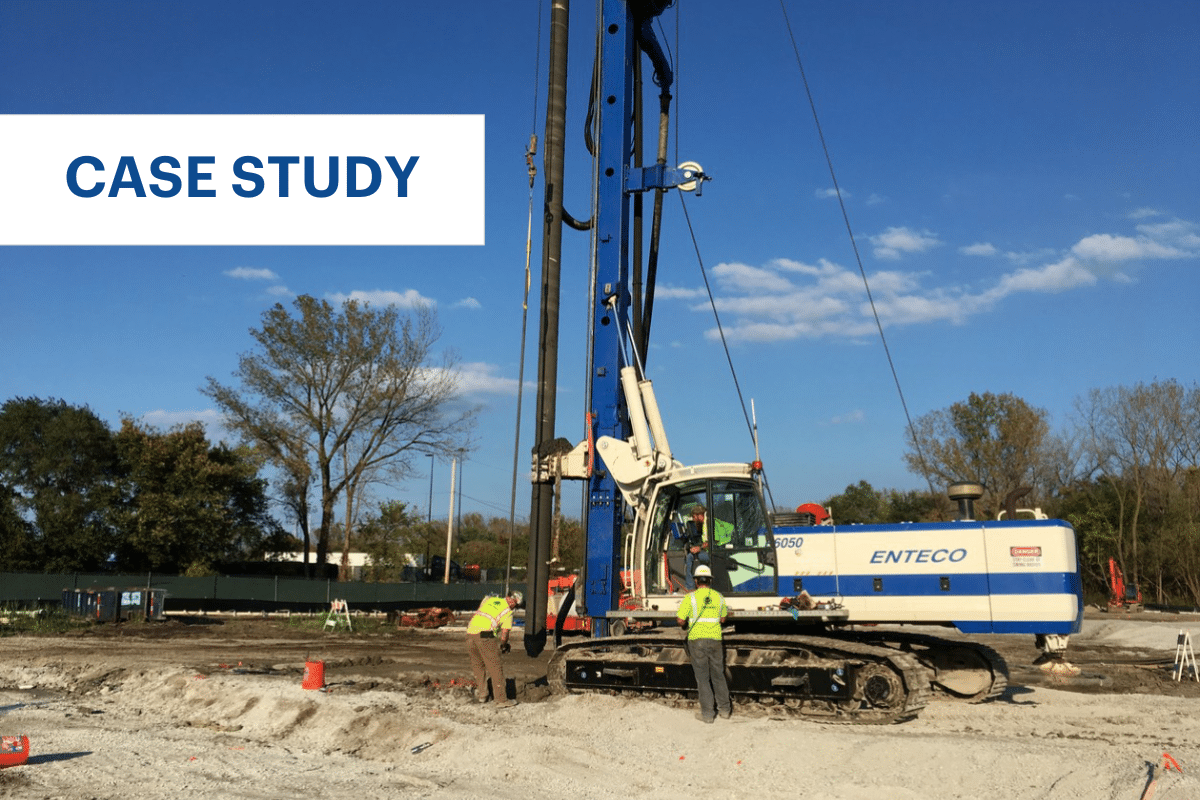

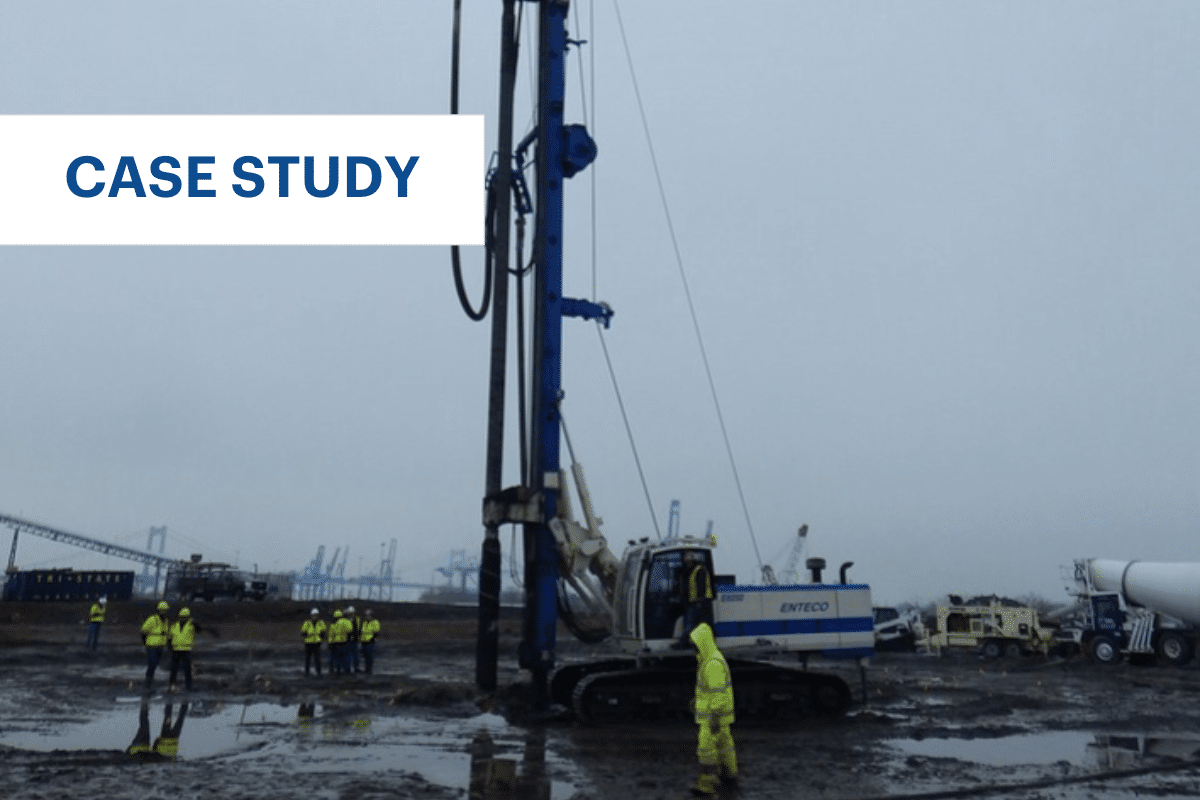

To accomplish the work, Menard USA’s engineers developed a design and specification that considered the soil parameters and the loads from the building. The stone columns were designed to limit settlement to 1-inch in total and ½-inch in differential for the spread footings and the wall footings. To penetrate the random fill, Menard’s ground improvement solution included pre-drilling each SC location to the design depth.

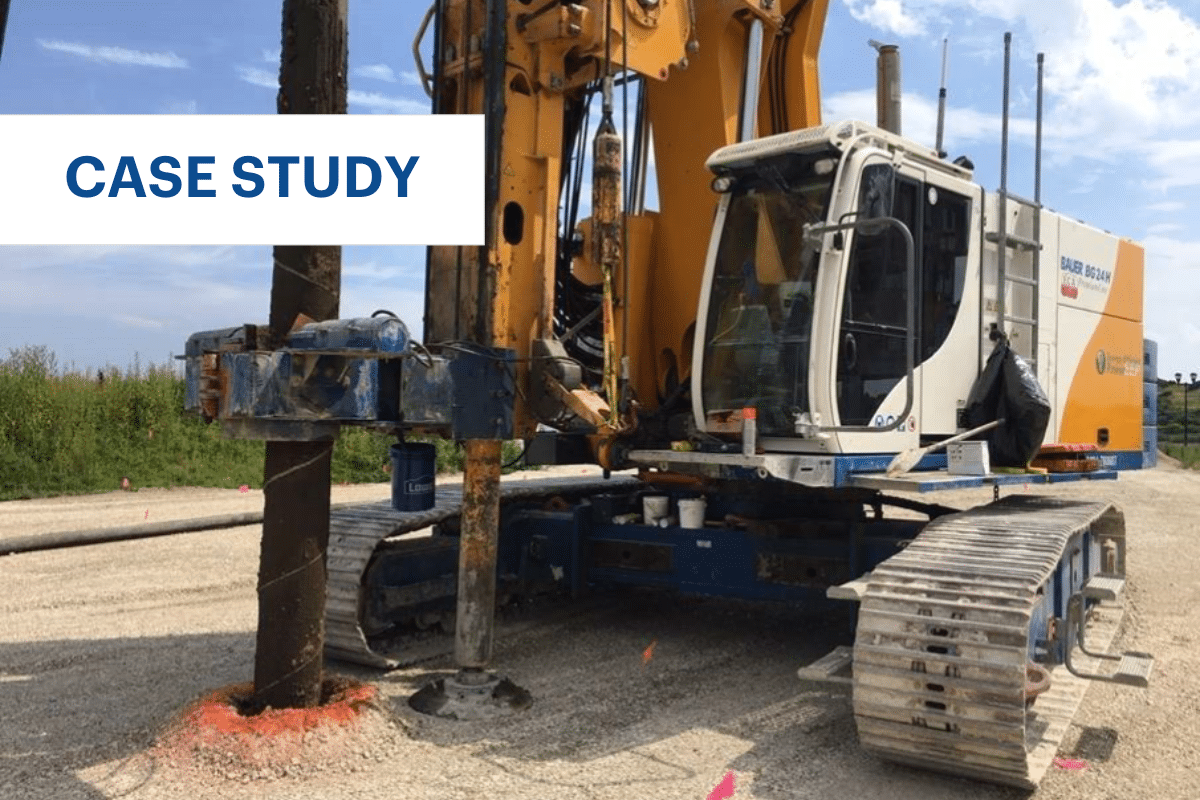

Due to the density and the potential for obstructions within the fill, Menard used a BG-20 drill rig to accomplish the pre-drilling. After each location was pre-drilled, the stone columns were installed using a vibratory technique to enhance compaction of the element and the surrounding ground. All work was completed per Menard’s in-house design and specifications.

During the project, Menard crews were challenged by heavy snow and rain, which caused stability issues on the working pad. Menard worked with the general contractor to ensure the working pad was maintained so that all work could be performed safely and productively. Menard ultimately installed 697 SCs across 2.5 acres, meeting the client’s requirements for quality and safety.

Print this resource