Grand Rapids Biodigester

Grand Rapids Biodigester

Project Details:

Owner: City of Grand Rapids

General Contractor: The Christman Company

Engineer: Tetra Tech

Approximate Key Quantities: Controlled Modulus Columns 1,364 EA.

Project Overview:

The City of Grand Rapids, MI, and Founders Brewing Co. proposed a joint venture on a $30 million biodigester at the city’s Water Resource Reclamation Facility. The biodigester would eliminate the need for a $90 million expansion of the reclamation facility, while also producing an estimated 60 percent of the electricity needs of the city’s Environmental Resource Recovery Facility.

Biodigesters mix organic waste, including food waste from venues such as Founders Brewing, with microorganisms in a sealed air-tight tank. The material is heated and sits for a prescribed period as the microorganisms break the material down. As the waste decomposes it creates biogas, which is about 60 percent

methane. The biogas is used to turn a turbine and generate electricity. The Renewable Natural Gas (RNG) produced can be used as vehicle fuel, which will eventually be used for Grand Rapids buses. The digester – a three-tank system – counts for $21 million of the $30 million project.

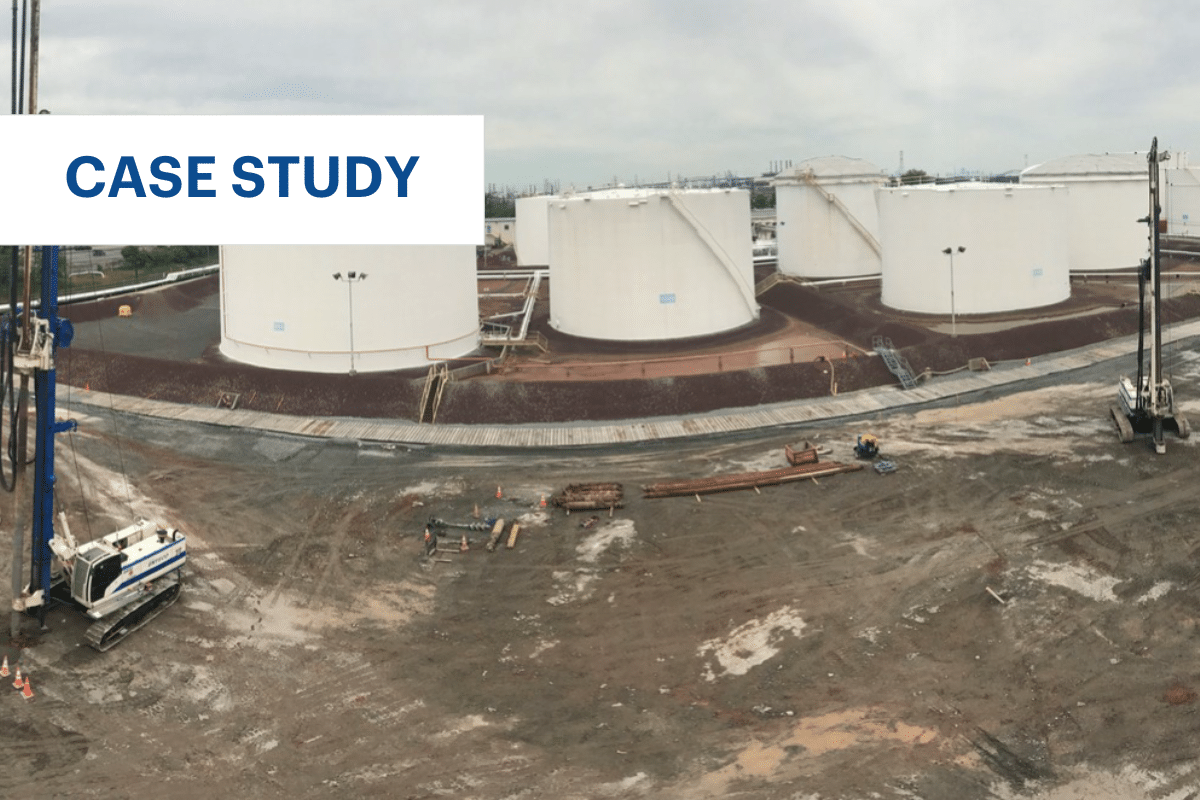

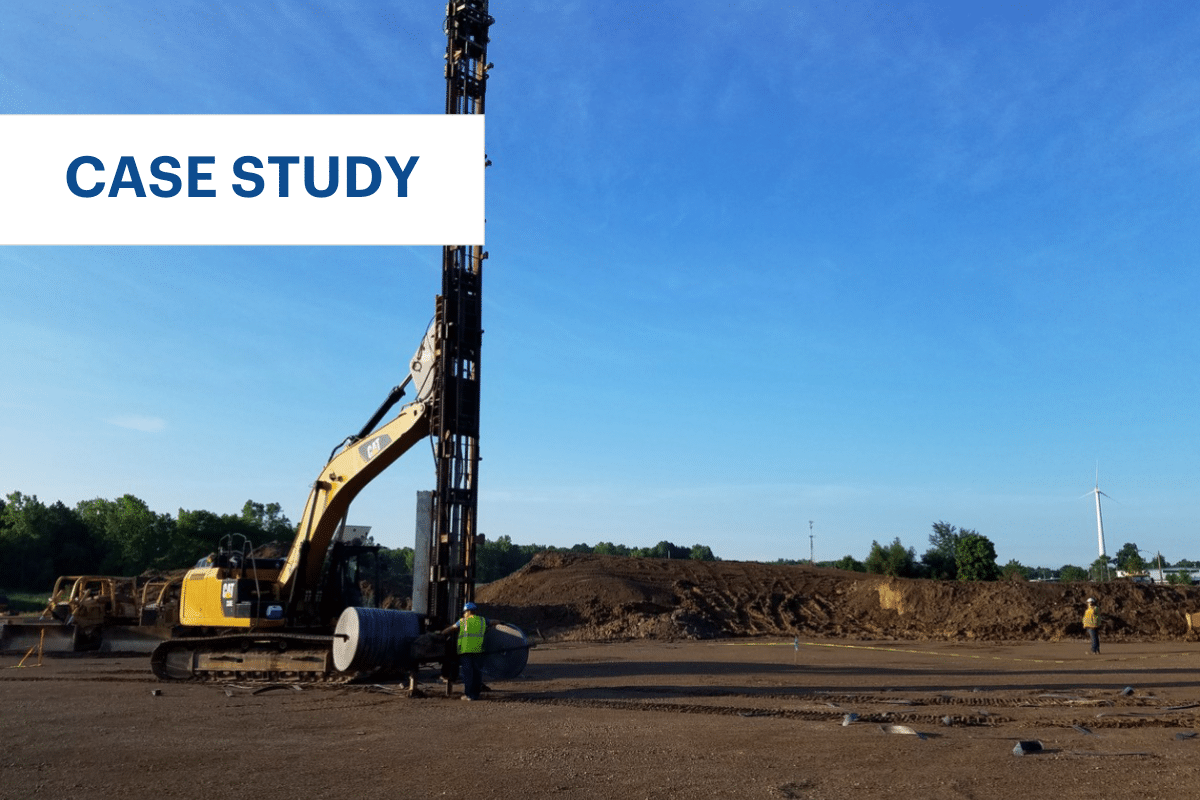

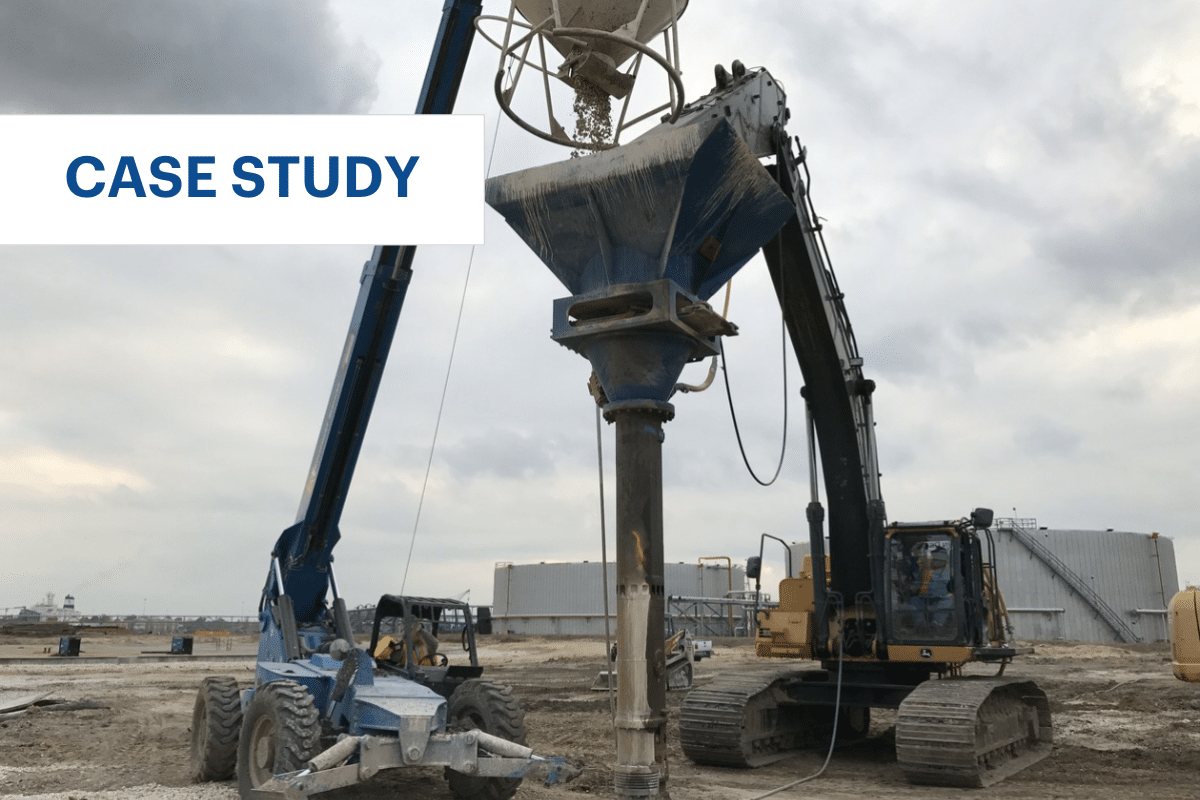

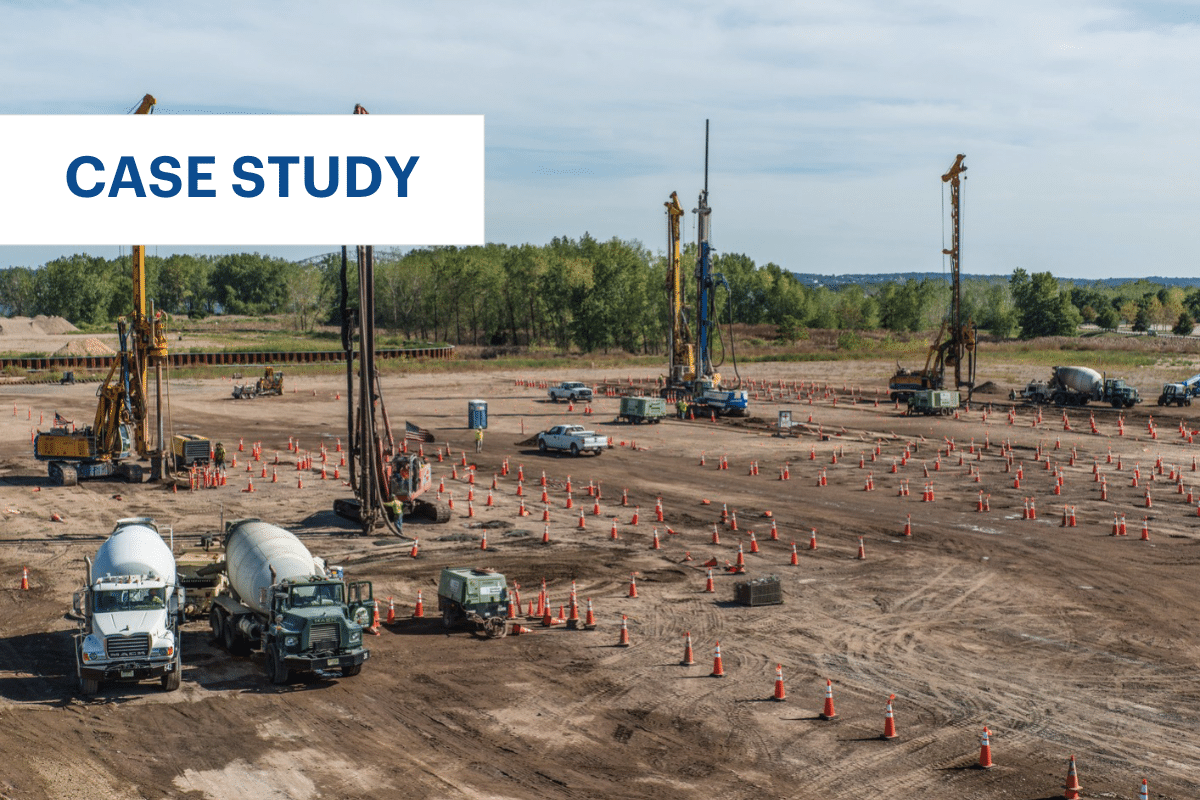

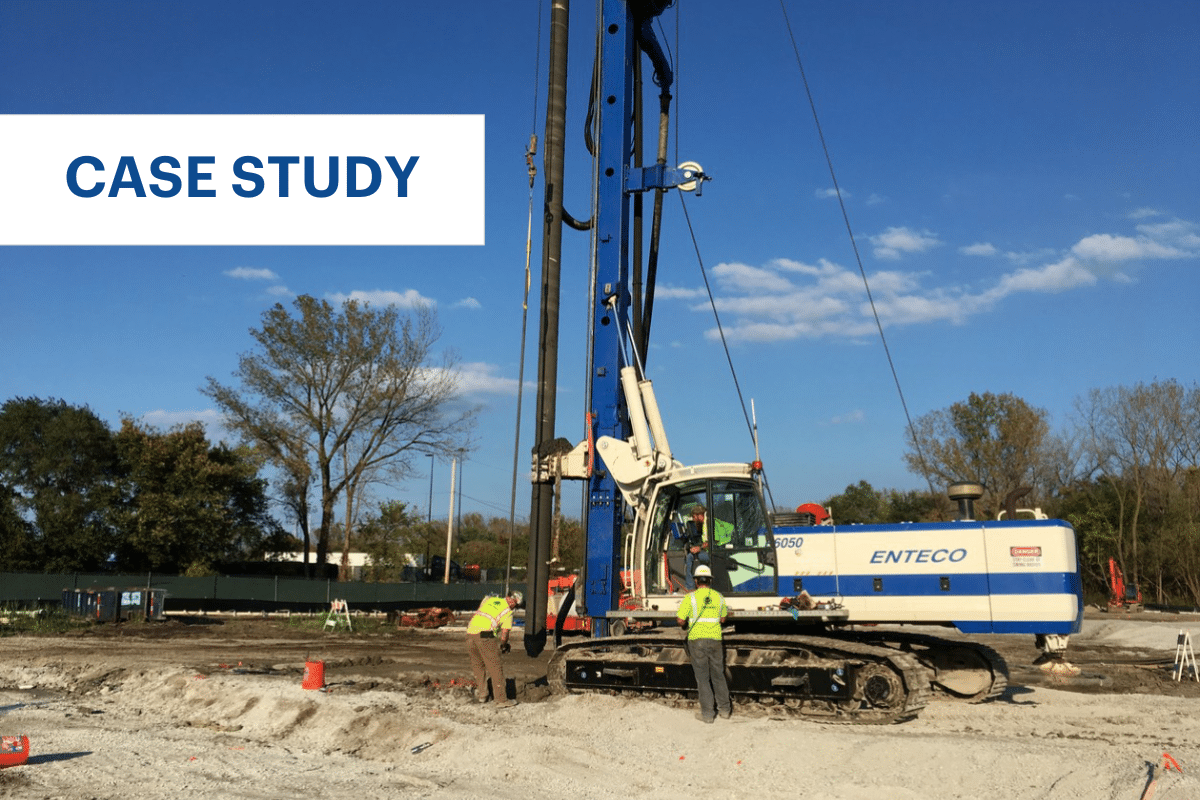

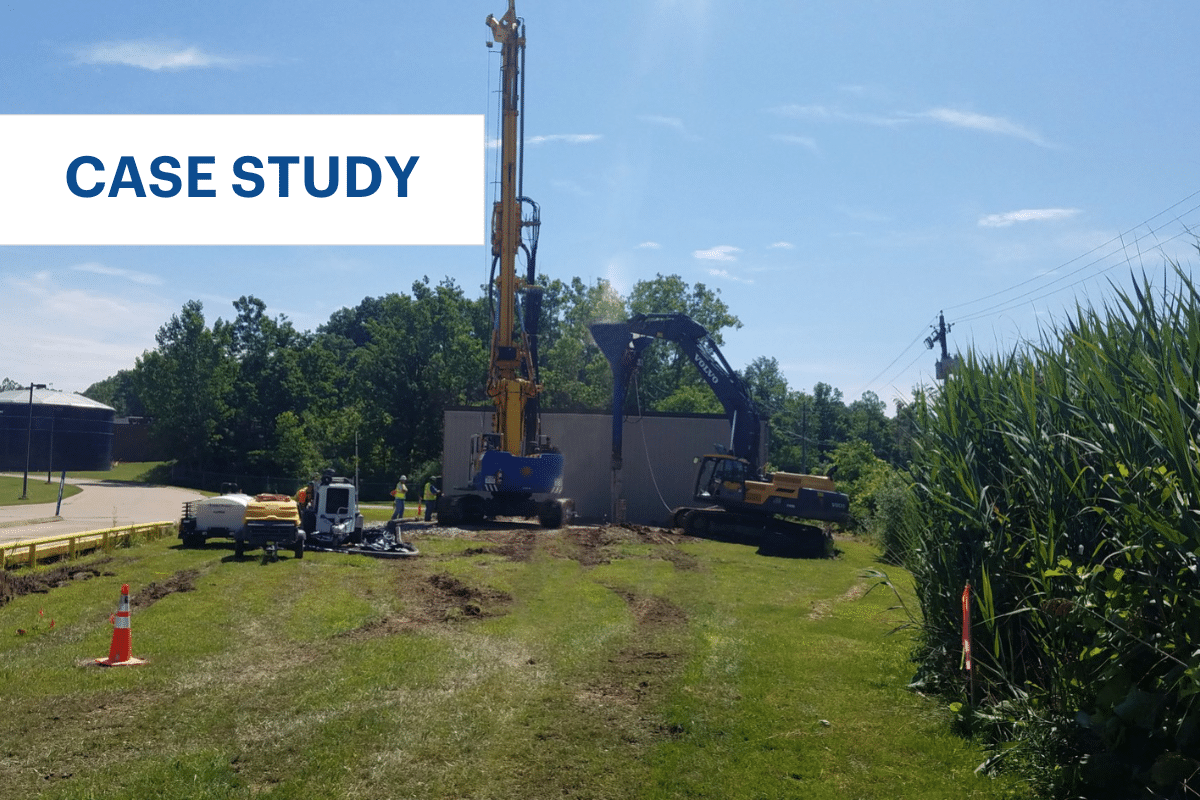

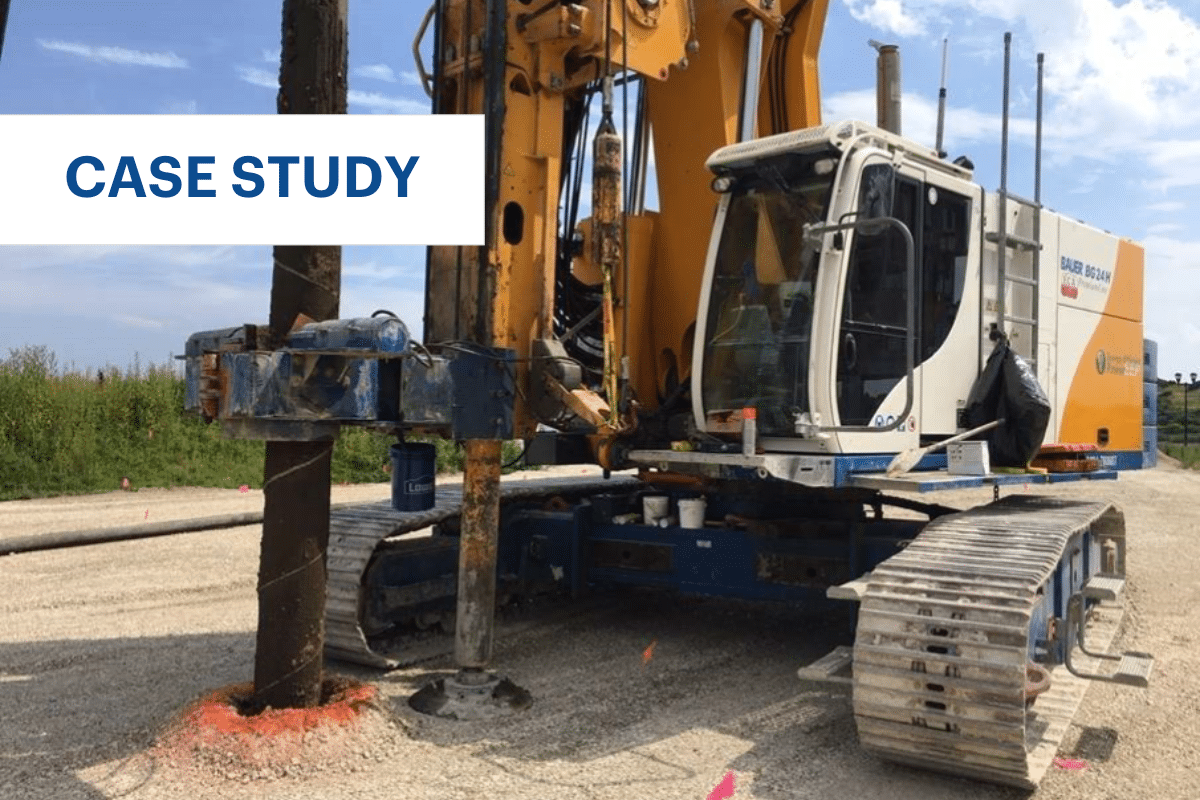

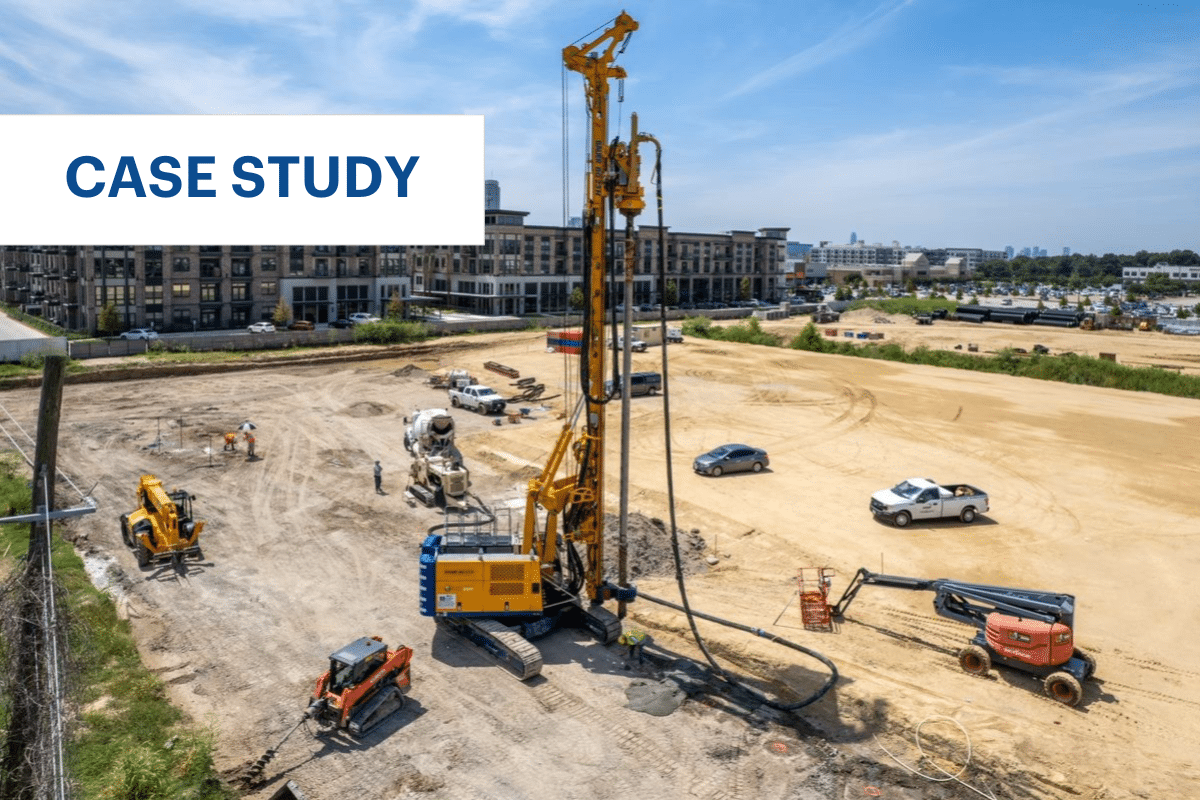

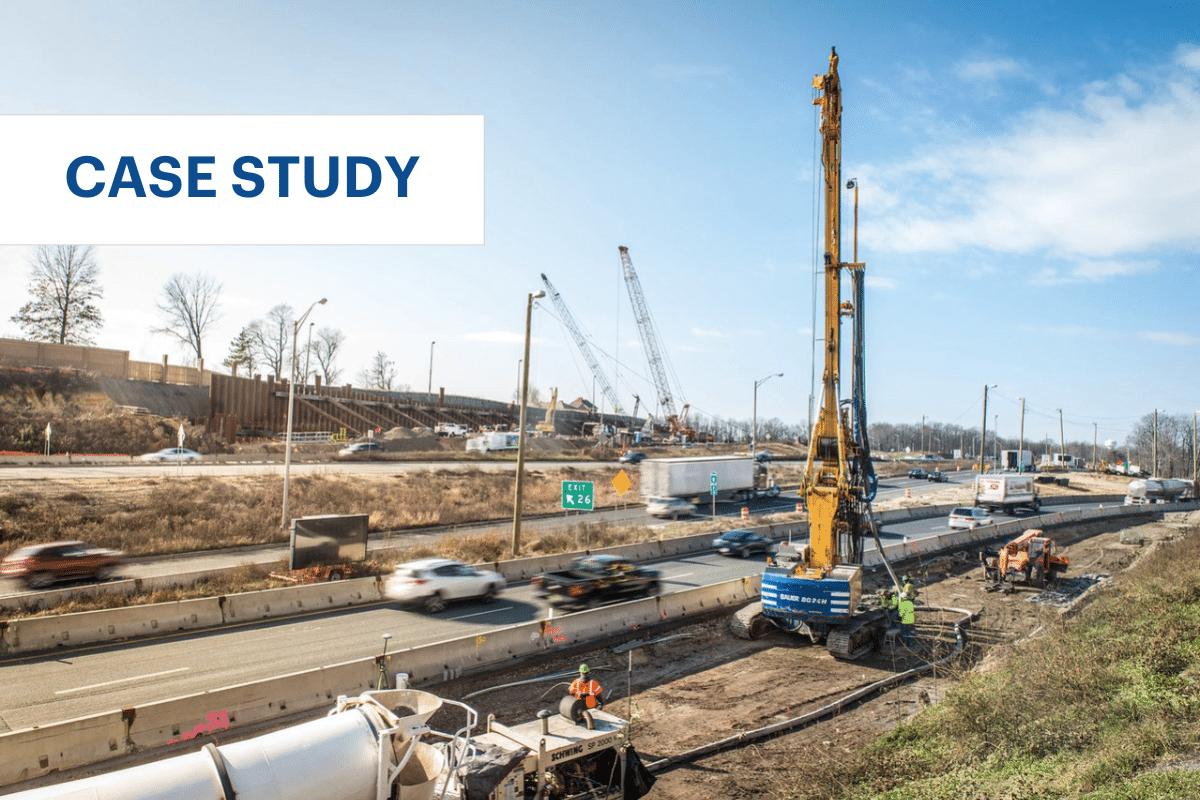

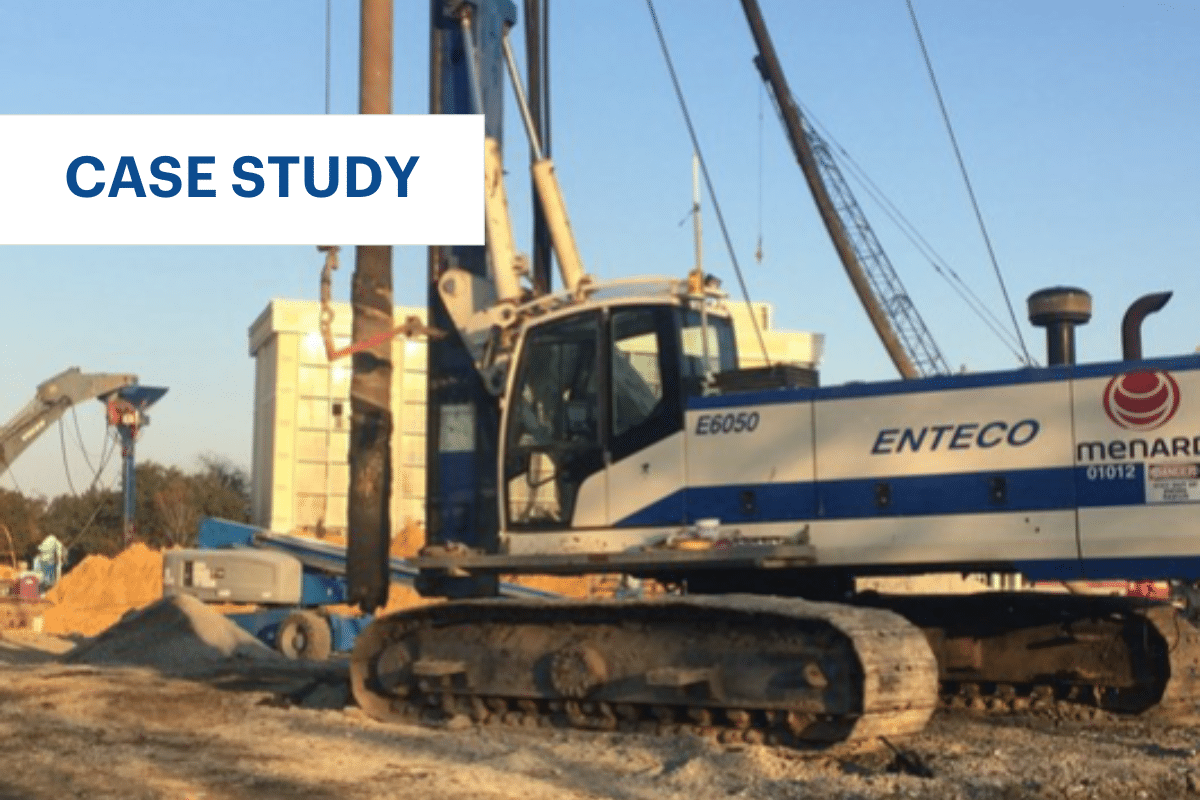

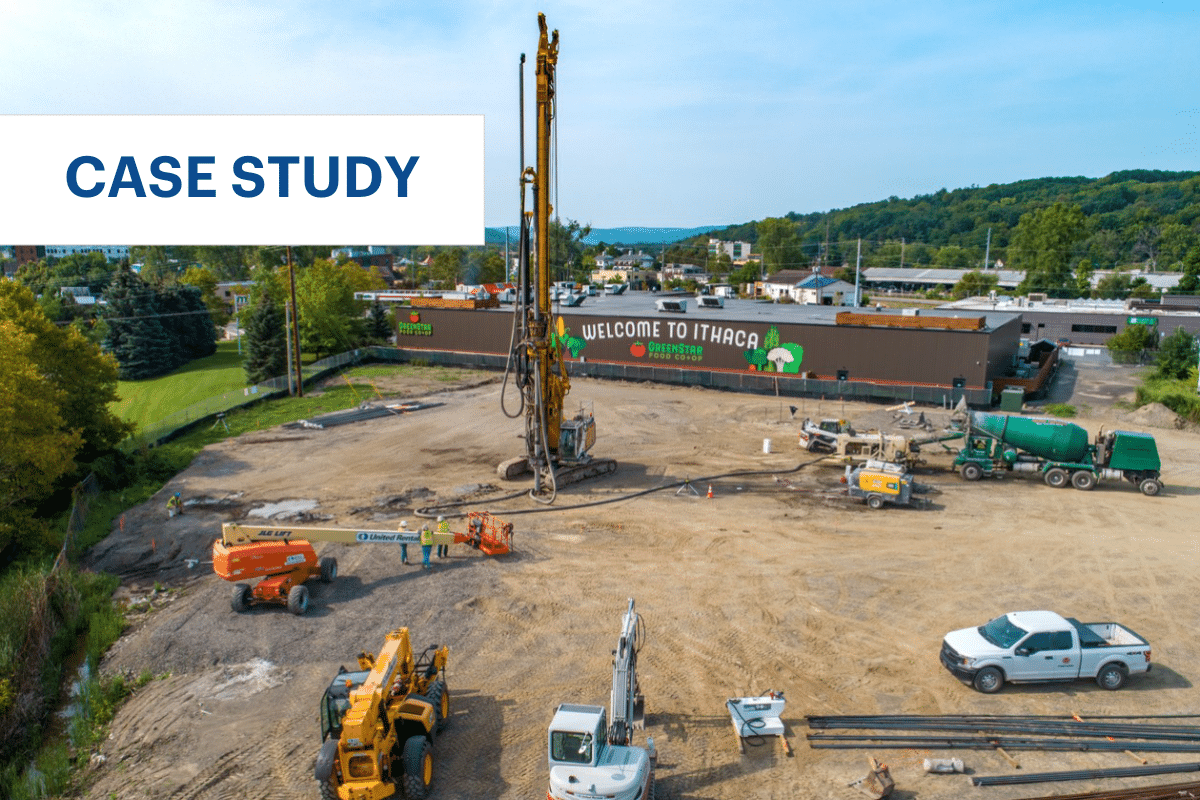

Due to the compressible nature of the soils at the site, Menard USA was contracted to provide ground improvement. Controlled Modulus Column (CMC)® rigid inclusions would be installed to support three 66-ft diameter, 80-ft tall “Digester” and “CW” tanks on an 85,000 sq-ft footprint.

Ground Conditions:

Solution:

In a joint venture with sister company Nicholson Construction Company (NCC), Menard installed 1,364 CMCs to an average depth of 13 ft and a maximum depth of 31 ft. The CMCs improved the bearing capacity and limited settlement of the overburden soils. NCC performed low-mobility grouting of bedrock voids.

The tanks required a bearing capacity of 5,000 psf. Associated pipe galleries, electrical rooms, truck loading pads, flares and transfer tanks required bearing capacities ranging from 2,000 to 4,000 psf. The design provided for 1 in of post-construction settlement with a differential settlement of less than a ½ in, meeting the performance criteria of the tanks. A challenge during the project was excessive groundwater, given the proximity to the Grand River. A de-watering contractor was used to aid in installation and to allow for placement and compaction of Menard’s Load Transfer Platform (LTP) in dry conditions.

In Grand Rapids, Menard USA installed 1,364 CMCs (totaling 17,721 LF) to support the construction of a three tank biodigester system.

Print this resource