Grant Street Speedway

Grant Street Speedway

Project Details:

Owner: Speedway LLC

General Contractor: R. Carlson & Sons

Date of Work: October 2016

Engineer: CTL Engineering, Inc.

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 134 EA.

Description:

When Speedway LLC set out to construct a new gasoline and convenience store at 3201 Grant Street in Gary, IN, a geotechnical investigation revealed that the soil was inadequate to support the five new structures: one convenience store, two canopies with fuel islands; two underground storage tanks. The selected site was located adjacent to a swamp with a shallow groundwater table, resulting in very soft soils.

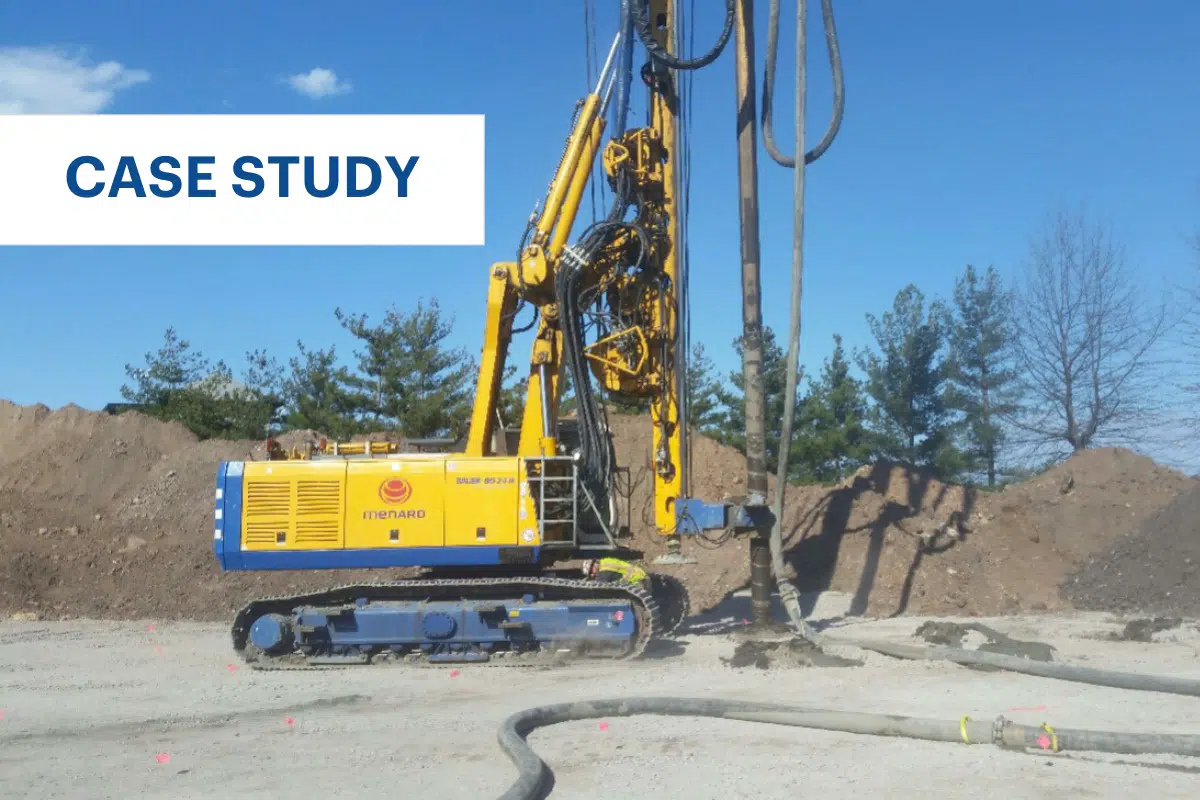

The owner awarded Menard design and installation of Controlled Modulus Column (CMC)® rigid inclusions to reduce settlement and provide suitable bearing capacity for the wall footings, slabs, and column footings of the Speedway gas station, as well as the other structures.

Ground Conditions:

Solution:

The Grant Street Speedway is the first Speedway facility to be supported by ground improvement elements. This created both opportunities and challenges for Menard management and crews when collaborating with the owner’s engineering team, who were more familiar with traditional deep foundations such as drilled shafts or piles. Because of this lack of experience with ground improvement, high levels of coordination and communication were needed to implement the CMC rigid inclusion design to a point where all parties felt comfortable.

The high water content in the very soft soils proved particularly challenging when installing the CMC rigid inclusions for the two underground storage tanks. These two areas required deep cut offs on the CMC rigid inclusions in order to have the top of the column below the bottom of the storage tanks. Continued collaboration between Menard and the general contractor’s team was needed to carefully perform the cutoffs in a manner that wouldn’t damage the integrity of the CMC rigid inclusions.

During installation, the grout pump was cut-off after grout had been placed to an elevation which was higher than the planned top of the column, but well below existing grade. The elevations of the CMC rigid inclusions were recorded and provided to the General Contractor. After the columns had cured, the general contractor excavated the two tank areas and completed the cut offs at depths of 10 to 12 ft below grade. Menard sent a Field Engineer to supervise the final stage of the column cut offs as an additional quality control measure.

A total of 134 CMC rigid inclusions were installed to maximum depths of 81 ft.

Print this resource