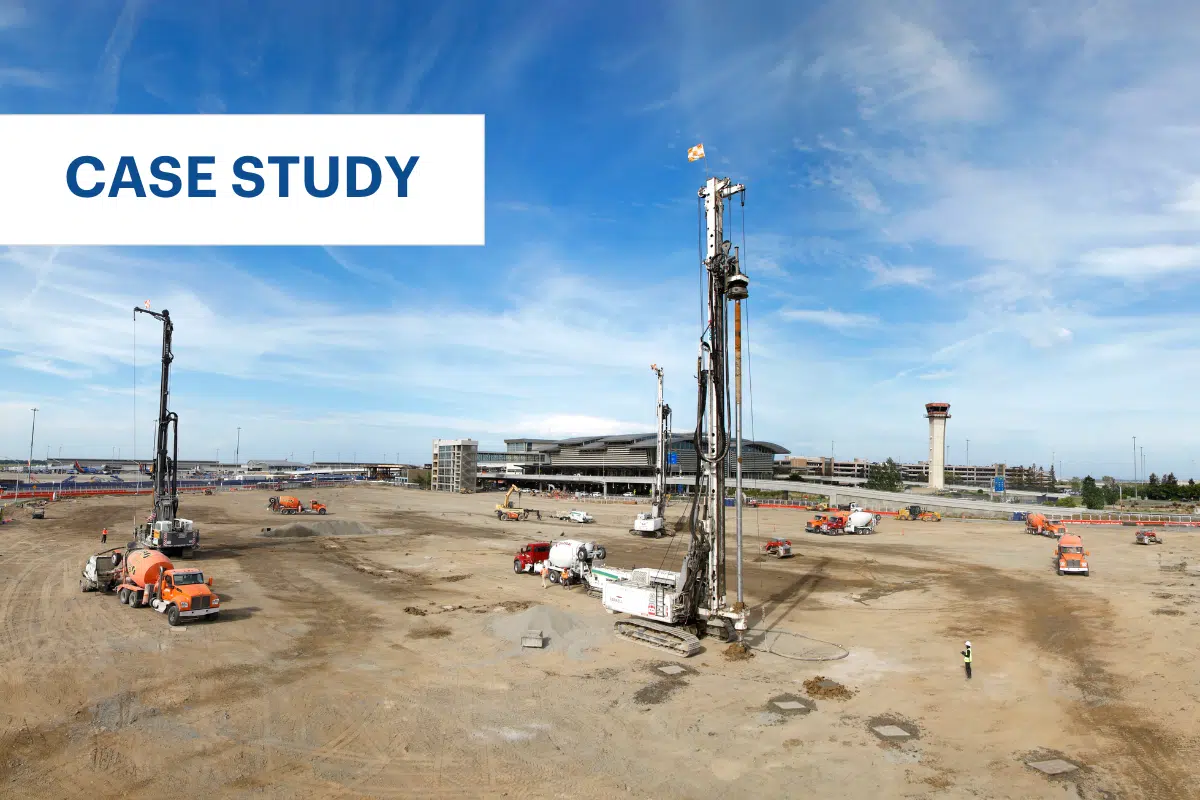

Greenside Aircraft Taxiway and Hangar Complex - CMCs

Greenside Aircraft Taxiway and Hangar Complex - CMCs

Project Details:

Owner: Naval Facilities Engineering Command

General Contractor: Walsh Construction Company

Date of Work: January 2017 - December 2017

Engineer: Patton, Harris, Rust & Associates

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 1,200 EA.

Description:

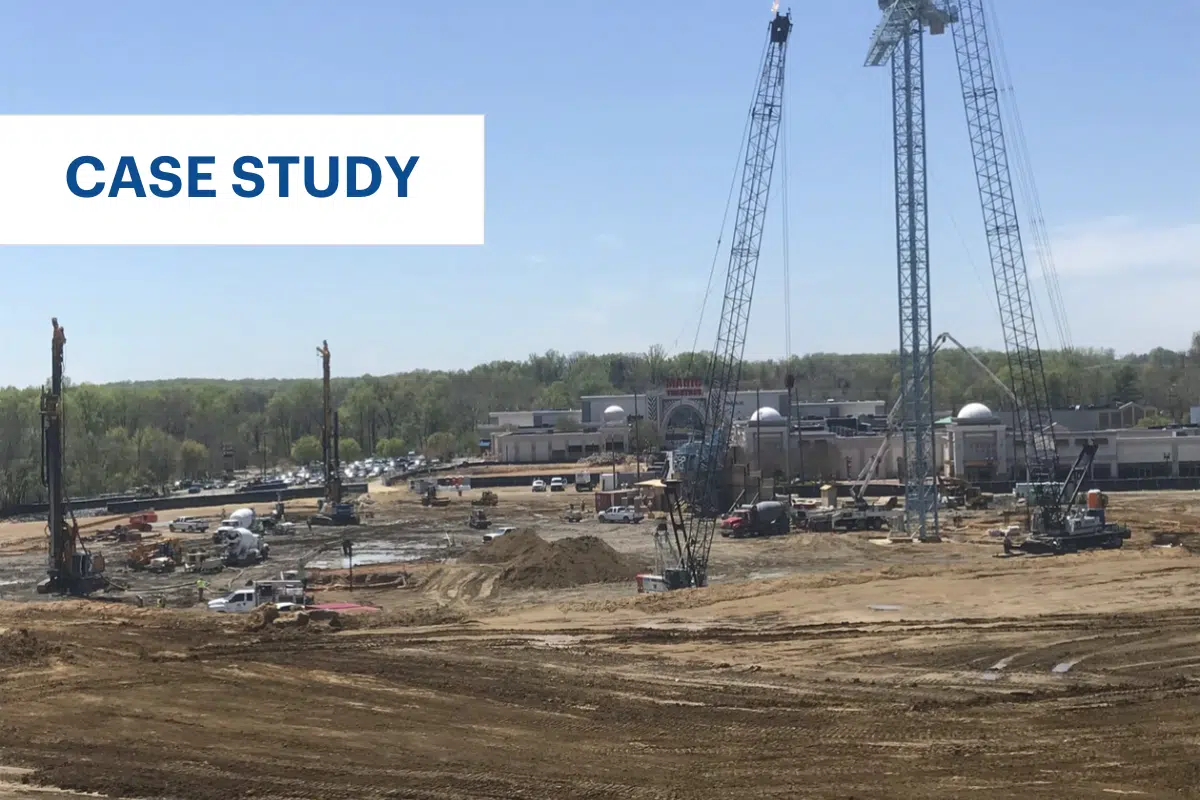

The Greenside Aircraft Taxiway and Hangar Complex is a large-scale public project at the Marine Corps Air Facility in Quantico, VA. The Greenside Type II Hangar will house the existing fleet of CH-53, new CH-53K Sikorsky Helicopters, and the proposed MV-22 Osprey aircraft. As part of the large design-build team, Menard provided ground improvement solutions to support the Greenside Type II Hangar foundations and slabs, adjacent concrete apron and several related support facilities.

Ground Conditions:

Solution:

Due to the extreme nature of the fatty clay deposits, many alternative deep ground improvement alternatives were not financially or technically feasible.

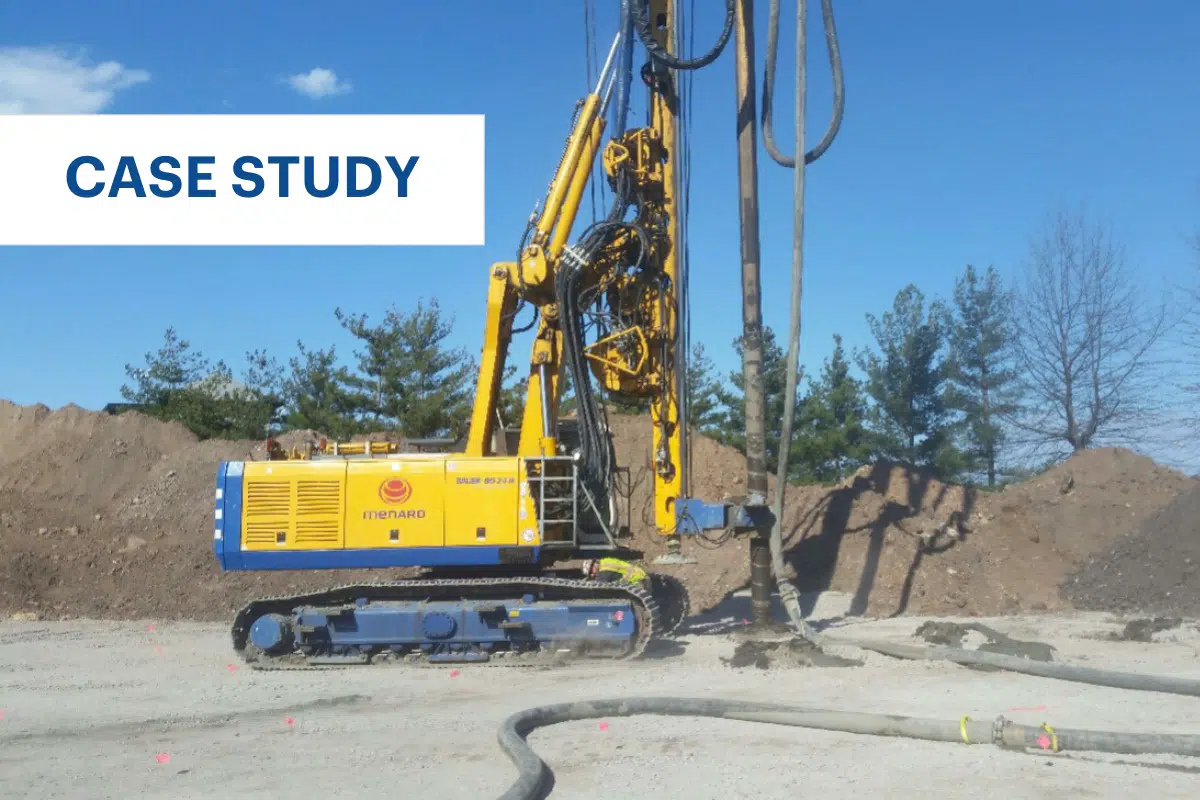

To support the hangar and facility foundations, Menard designed a solution using Controlled Modulus Column (CMC)® rigid inclusions that allowed the General Contractor to significantly reduce the thickness of the slabs and reduce the amount of reinforcing steel required in the footings and slabs. The CMC rigid inclusions allowed construction to proceed as if the site's soils were of much greater strength and quality than what was actually the case before ground improvement.

Approximately 1,200 CMC rigid inclusions were installed beneath the multiple structures to an average depth of 64 feet and a maximum depth of more than 73 ft below grade.

Print this resource