Illinois 226 DOT Grand Avenue

Illinois 226 DOT Grand Avenue

Project Details:

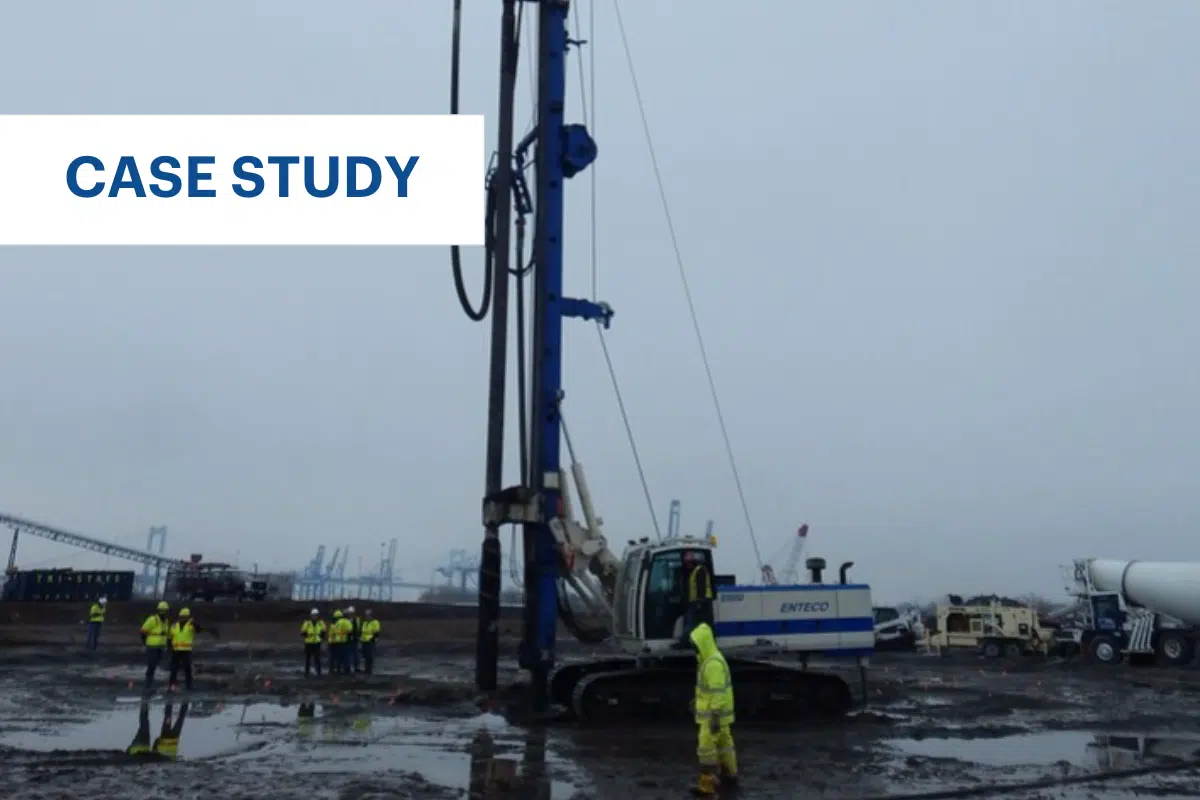

Owner: Illinois Department of Transportation

General Contractor: Lake County Grading Company

Date of Work: May 2016 - August 2016

Engineer: Wang Engineering Inc. & Baxter and Woodman

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 1,991 EA.

Description:

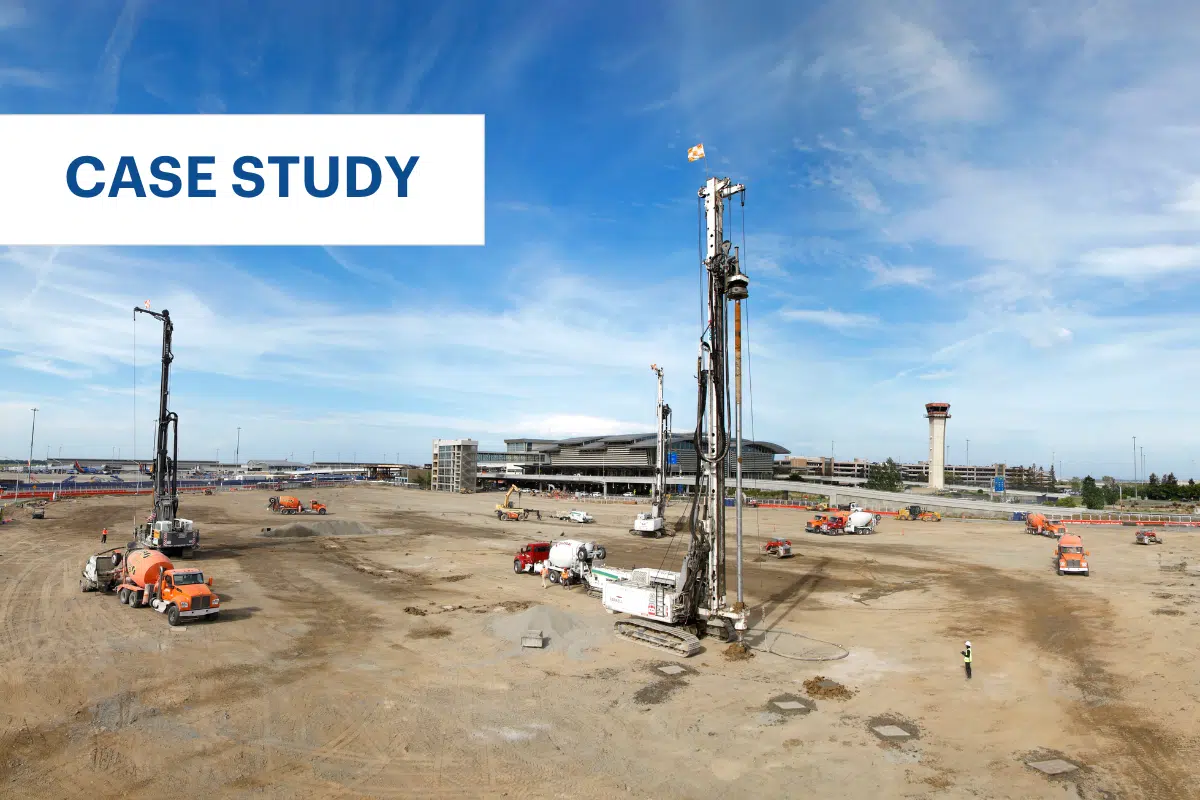

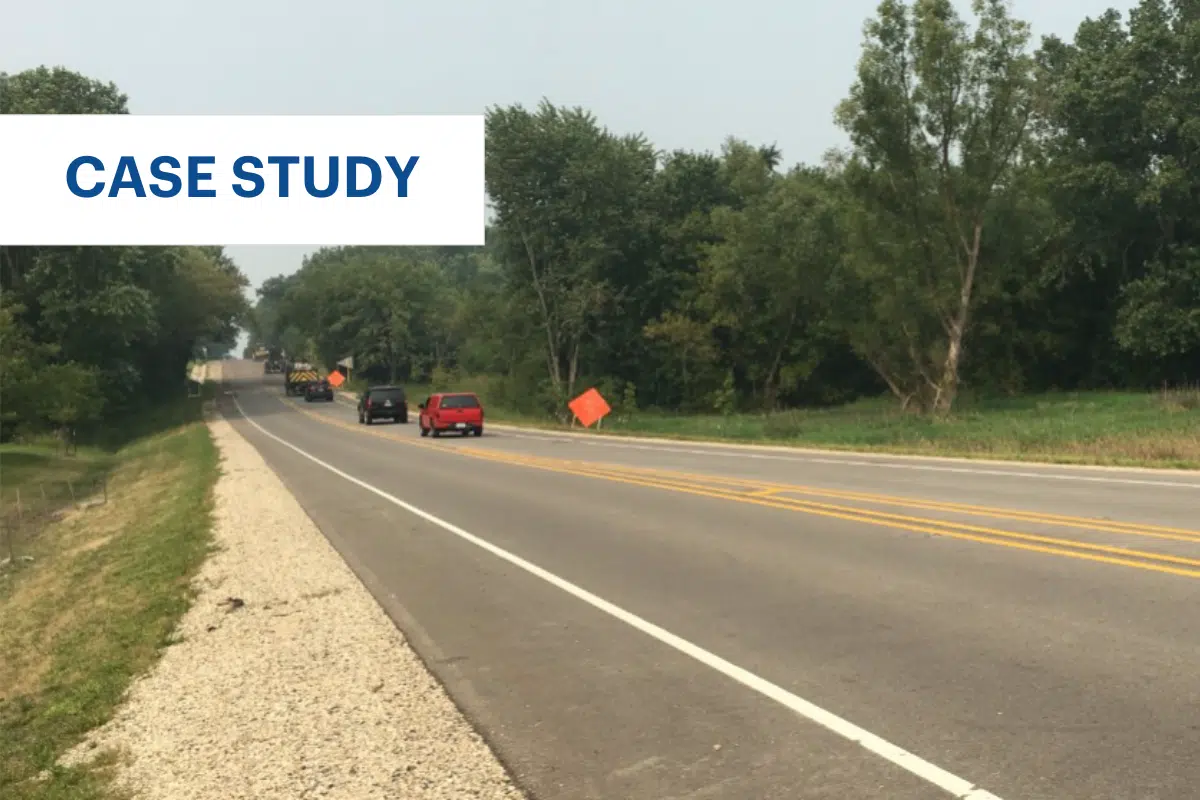

Known as one of the "titans of east-west travel" in Illinois, Grand Avenue in Lake Villa was the site of a proposed bridge replacement and roadway expansion by the Illinois Department of Transportation (IDOT). Grand Avenue carries 41,300 vehicles per day past Gurnee Mills and 35,700 through the Gurnee retail sector west of Hunt Club Road.

The original land bridge, supported on timber piles and measuring 870 ft, had 15- to 56-inch voids below, resulting from the consolidation of the underlying organic soils. The expansion portion of the project at the intersection of Grand Avenue and Fairfield Road called for doubling the size of the roadway from 2 to 4 lanes, including a 4-ft shoulder on each side.

Due to the compressible nature of the soils at the site, settlement was predicted unless ground improvement was provided.

Ground Conditions:

The soil profile consisted of fibrous peat and organic soils up to 20 ft thick, overlying silty loam and sand up to 6 ft in thickness. The peat and associated organics were very soft with undrained shear strength of approximately 200 psf. The silty loam and sand were loose to medium dense. The stiff silty clay had an average undrained shear strength of 2,740 psf.

Solution:

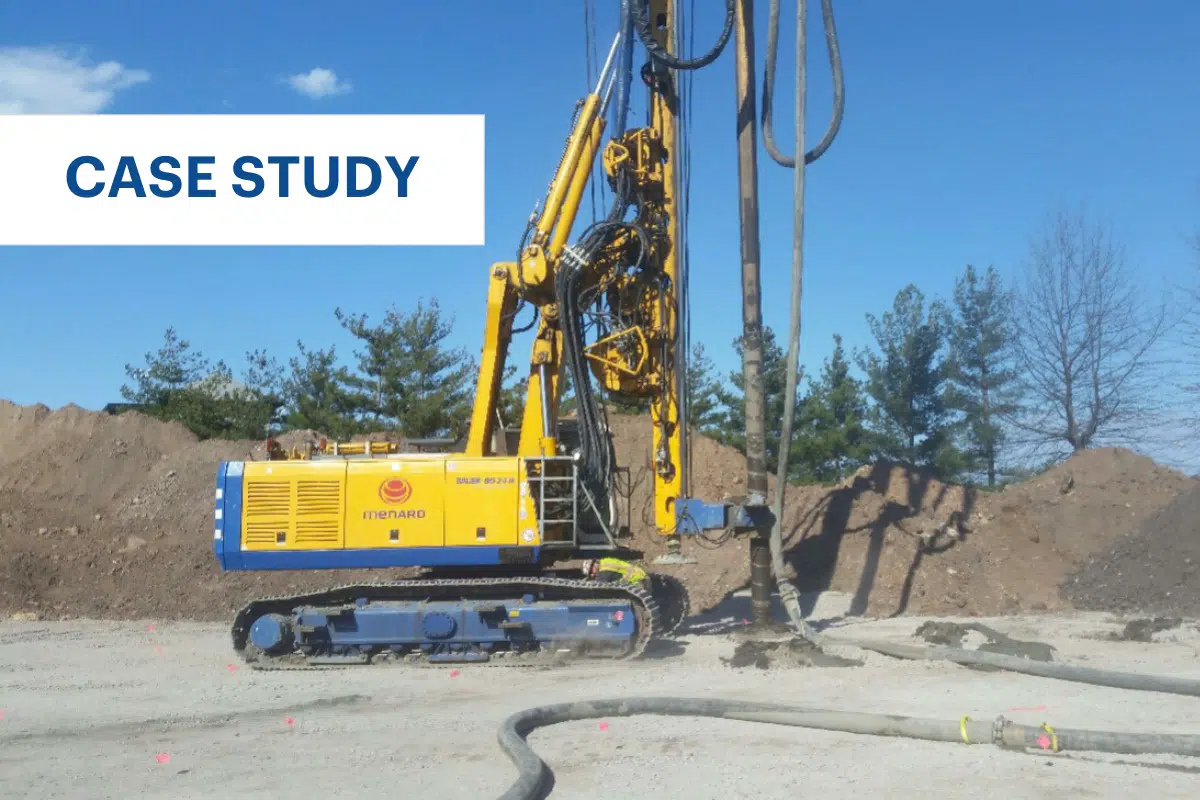

Controlled Modulus Column (CMC)® rigid inclusions and wick drains were installed from el. +792.0, which was the top of a 3 ft working platform. The working platform was reinforced with two layers of biaxial geogrid. The wick drain working platform included 1 ft of CA-7 washed stone at the base to improve drainage.

Wick drains were installed at a typical 6 x 6 ft spacing beneath the north embankment. Spacing was decreased to 4 x 4 ft after a failure occurred during construction. CMCs, 12.5 inch in diameter, were installed at 6 x 6 ft spacing beneath the north embankment and 7 x 7 ft beneath the embankment crest and south slope. CMCs extended through the peat and silty loam with sand and terminated in the stiff silty clay. All CMCs were cut off 12 inches into the working pad.

Wick drains helped to expedite consolidation of the compressible soil strata. Work was completed in one continuous phase and met the client’s requirements for safety, quality and schedule.

Print this resource