JDA Storage Building

JDA Storage Building

Project Details:

Owner: Johnson Development Associates (JDA)

General Contractor: Franjo Construction

Date of Work: December 2018 - January 2019

Engineer: Geo-mechanics, Inc.

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 416 EA.

Description:

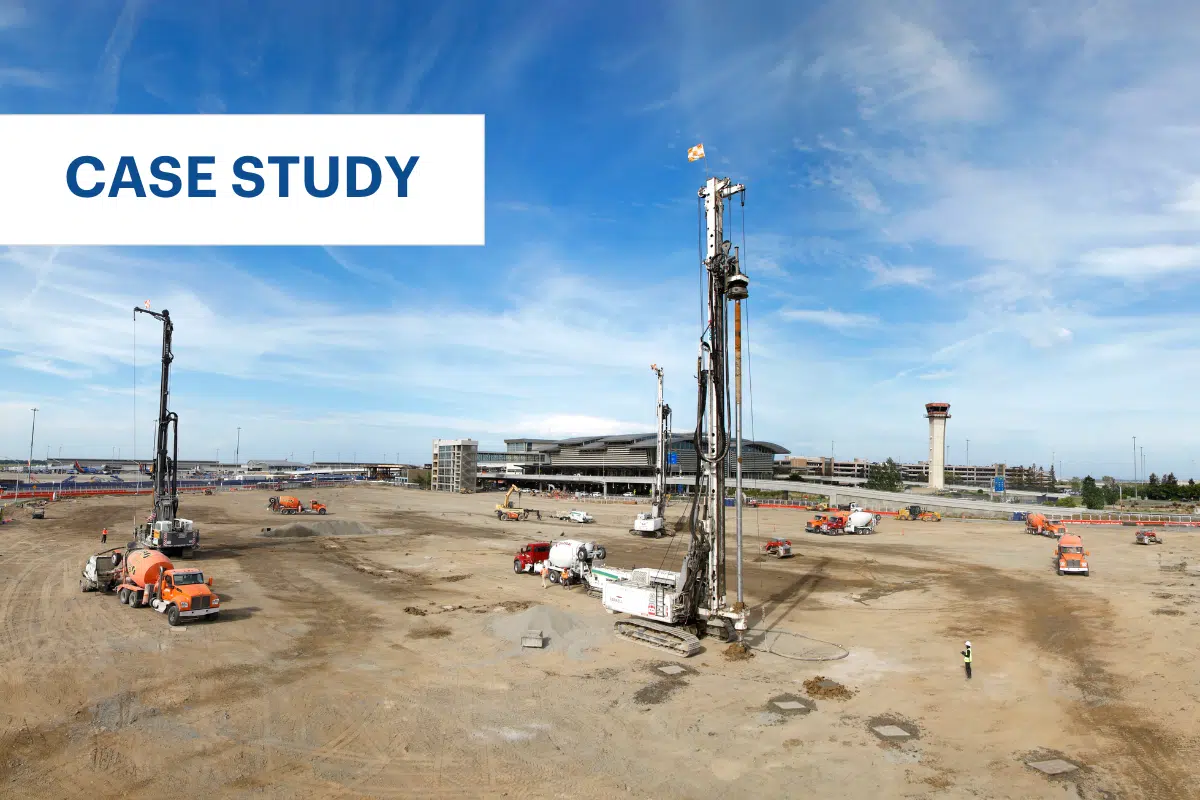

Johnson Development Associates (JDA), which initially focused on the development of local industrial and commercial property, has steadily grown into a multi-division real estate developer of industrial, multifamily, self- storage and commercial properties with a rapidly expanding national footprint. In Bridgeville, PA, JDA proposed the construction of a self-storage facility – Extra Space Storage – to serve residents in suburban Pittsburgh.

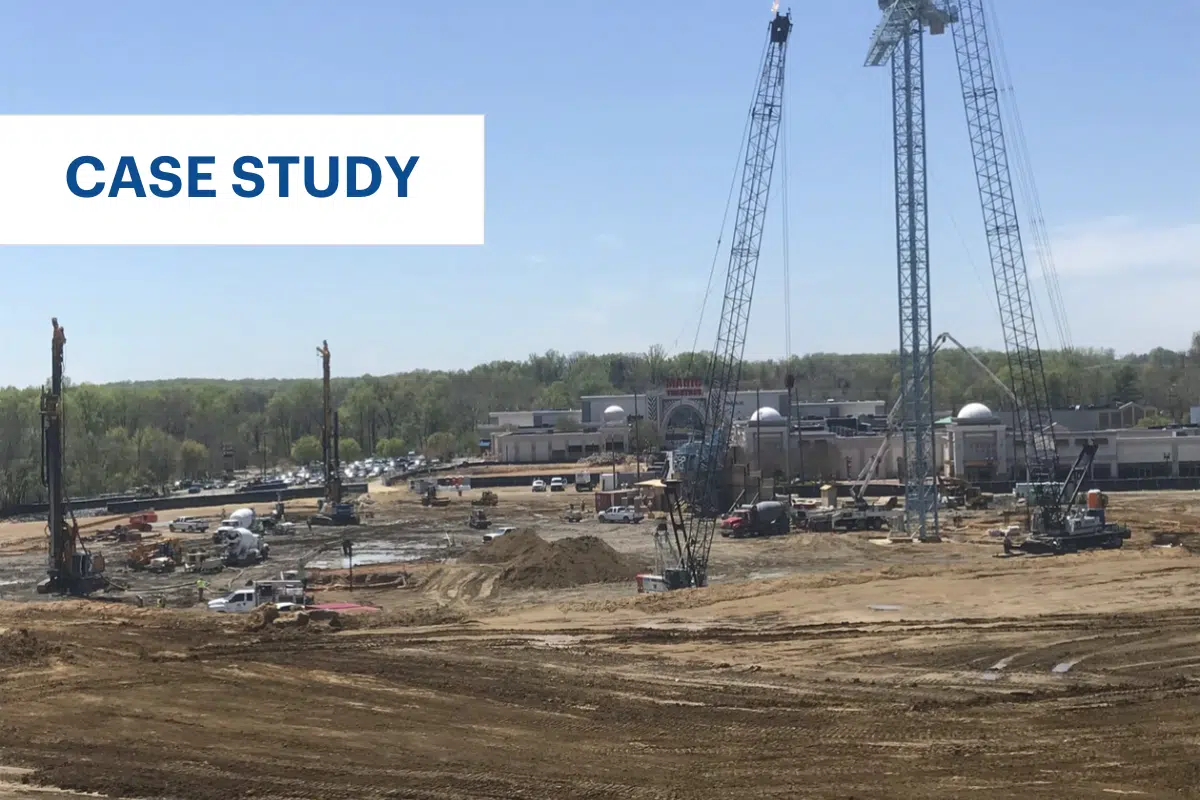

The three-story building would feature indoor and drive-up self-storage units ranging in size from 4’x5’ to 10’x25’. There is first-floor and elevator access, along with security measures such as electronic gate access and video surveillance. The building footprint measures 36,000 square ft with a total of 108,000 square ft of storage space available in the facility.

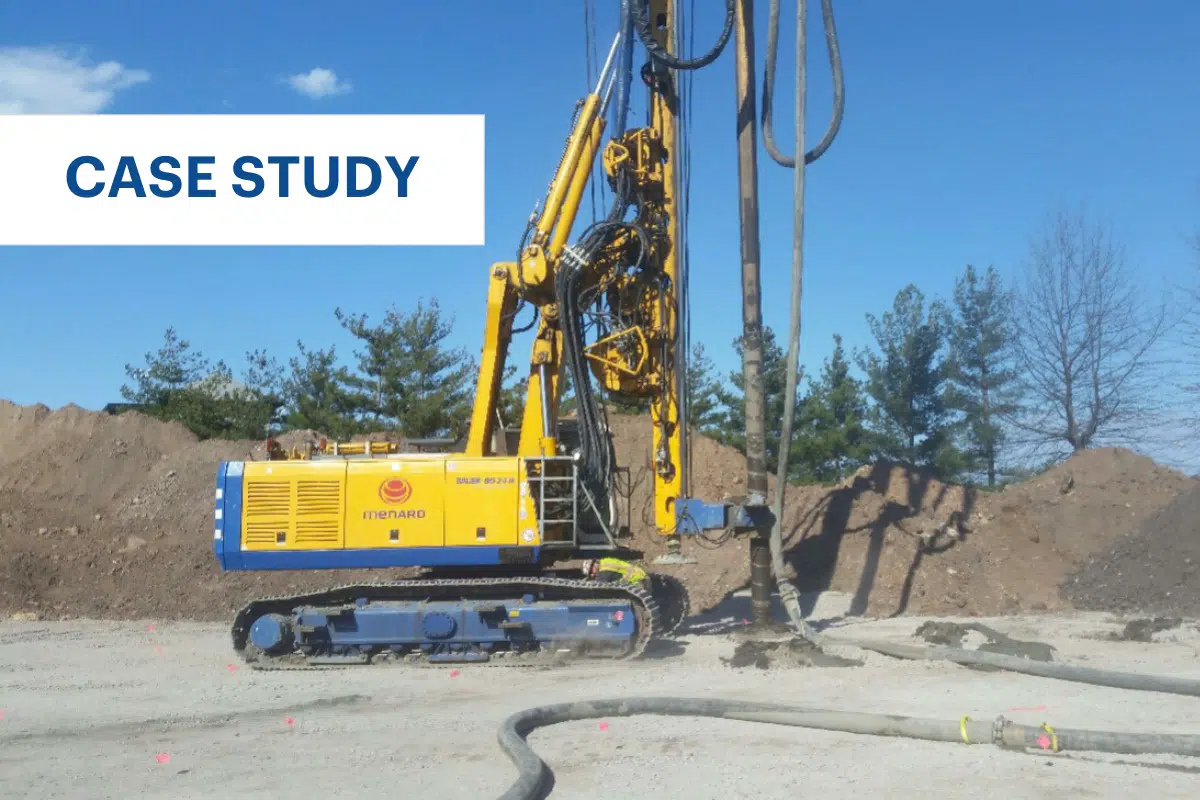

Due to the presence of both compressible and potentially expansive soils at the site, Menard Group USA was contracted to provide ground improvement support by installing Controlled Modulus Column (CMC)® rigid inclusions.

Ground Conditions:

The site is underlain by a soft to medium stiff brown silty clay fill with traces of carbonaceous shale. Swell tests were performed on the shale from the fill and it was determined that the shale was potentially expansive. Under the clayey fill was limestone interbedded with shale and claystone.

Solution:

Augercast piles with significant soil undercutting was considered for foundation support, however Menard provided an economical and time- saving value engineered (VE) solution with CMC rigid inclusions. The CMC design and the use of void forms to account for swelling, eliminated the need for undercutting and removing large amounts of spoils. Menard’s solution included the use of 416 CMCs that were installed beneath the spread and strip footings to a maximum depth of 35 ft. A portion of the CMCs were reinforced and connected to the footings to provide resistance to uplift.

The design provided 1 in of post- construction settlement with less than a ½-in differential settlement, meeting the building’s performance criteria. Design bearing pressures were 4.0 ksf. The use of CMCs in lieu of augercast piles allowed for the elimination of grade beams.

Because work was done in the winter months, maintaining the work pad created a challenge. Menard worked closely with the general contractor to keep the work pad safe and stable. Work was completed in four weeks.

To support the construction of a three- story self-storage facility, Menard Group USA installed 416 CMC rigid inclusions. The CMC design addressed both compressible and expansive soils and allowed for the elimination of augercast piles and significant soil undercutting. The project was completed in a safe and timely manner with excellent coordination between Menard and the general contractor. This project represents just one of several self-storage facilities that Menard has supported on CMCs.

Print this resource