Jefferson Transload Tank 2301

Jefferson Transload Tank 2301

Project Details:

Owner: Jefferson Railport Terminal, LLC

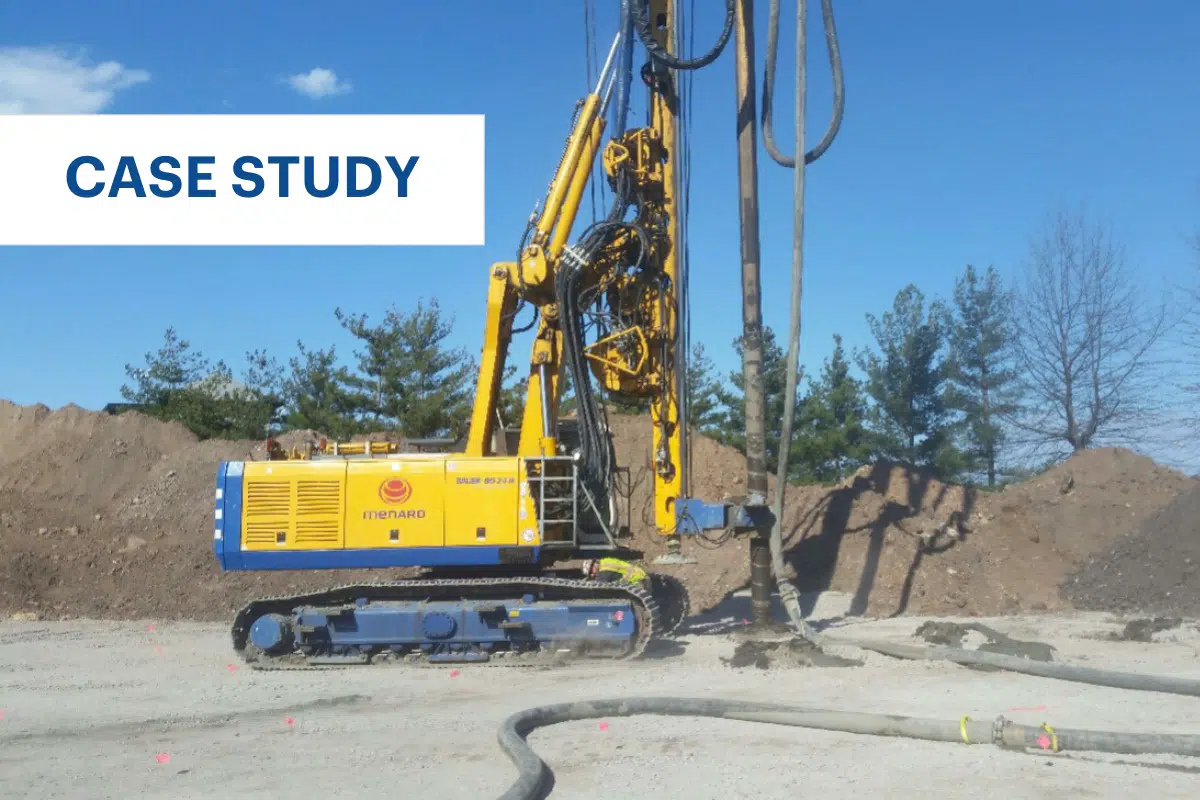

General Contractor: Menard USA/Kelley Construction, Inc. (sub)

Date of Work: November 2016 - January 2017

Engineer: Tolunay-Wong Engineers, Inc.

Approximate Key Quantities: Bi-Modulus Columns (BMC)® - 555 EA.

Description:

The Jefferson Energy Terminal facility is located along the east bank of the Neches River in Beaumont, TX, and is part of one of the busiest ports in the United States. When Jefferson Energy wanted to add a new 200-ft diameter oil product storage tank to their facility, it was determined that the site’s soils could not support the tank’s anticipated loads.

Menard proposed a ground improvement solution of Bi-Modulus Column (BMC)® rigid inclusions to help stabilize the soils and support the tank. Menard acted as General Contractor and subcontracted Kelley Construction, Inc. to carry out the civil scope of the tank foundation.

Ground Conditions:

The site soils are characterized by a medium dense to very loose sand layer extending to 28 ft in some areas, and a very loose clayey sand layer extending 19 to 28 ft in other areas. These sand layers are underlain by firm organic clay imbedded with silt seams and wood fragments from 28 to 38 ft, and in other areas extending as deep as 43 ft. Underneath this clay layer is a dense to medium dense clayey sand layer extending to depths of up to 73 ft.

Solution:

Prior to Menard involvement, the proposed site of the storage tank was already at the desired finished grade. Traditional foundation support solutions would require either a thicker Load Transfer Platform (LTP) – which would raise the grade – or excavation and backfill to bring the LTP to grade. Both options would result in significant costs to the client.

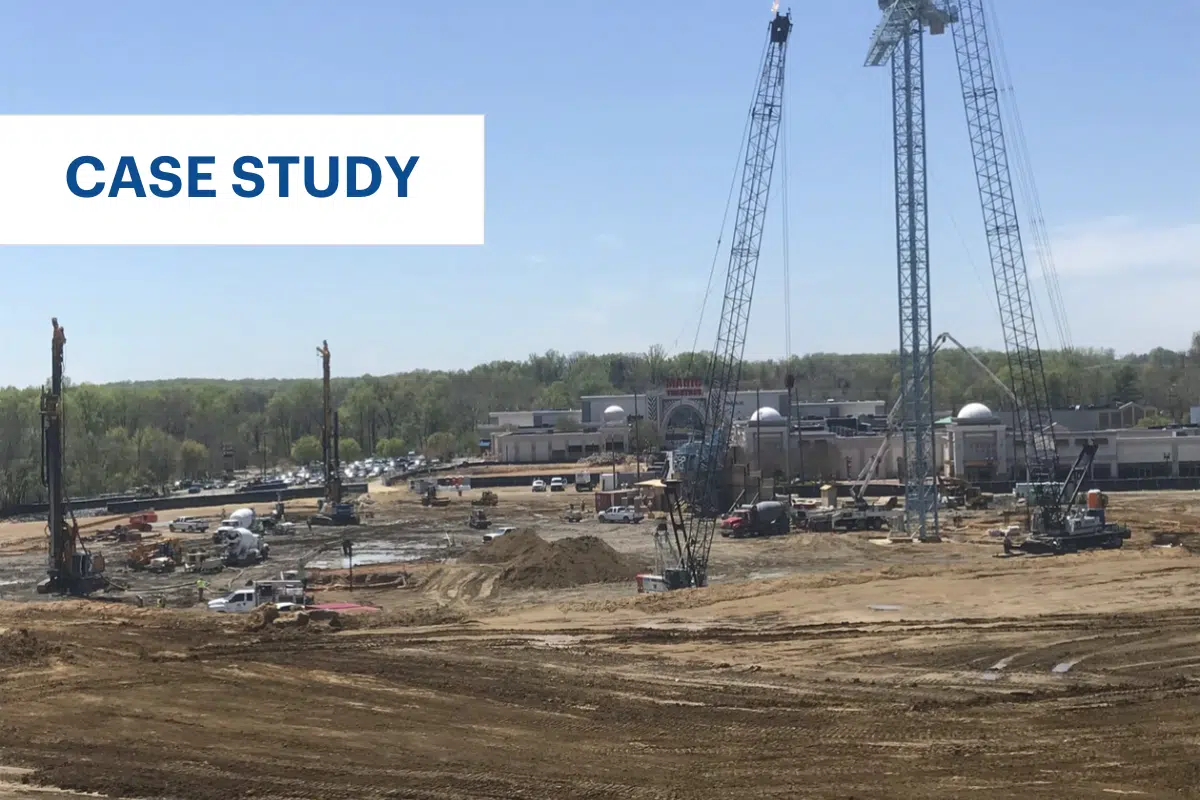

Menard’s innovative ground improvement solution of BMCs were a good fit for this project because the vibro stone portion of the column provides load transfer into the Controlled Modulus Column (CMC)ᵀᴹ rigid inclusion portion of the column. This means a thinner LTP, resulting in minimal changes to surface elevations, no site excavation, and cost savings for the client. A total of 555 BMCs were installed to maximum depths of 63 ft.

Print this resource