Kingsland Landfill

Kingsland Landfill

Project Details:

Owner: Russo Development/Forsgate Industrial Partners

General Contractor: Russo Development

Date of Work: September 2019 - June 2020

Engineer: SESI Consulting Engineers

Approximate Key Quantities: Dynamic Compaction - 77,962 drops

Description:

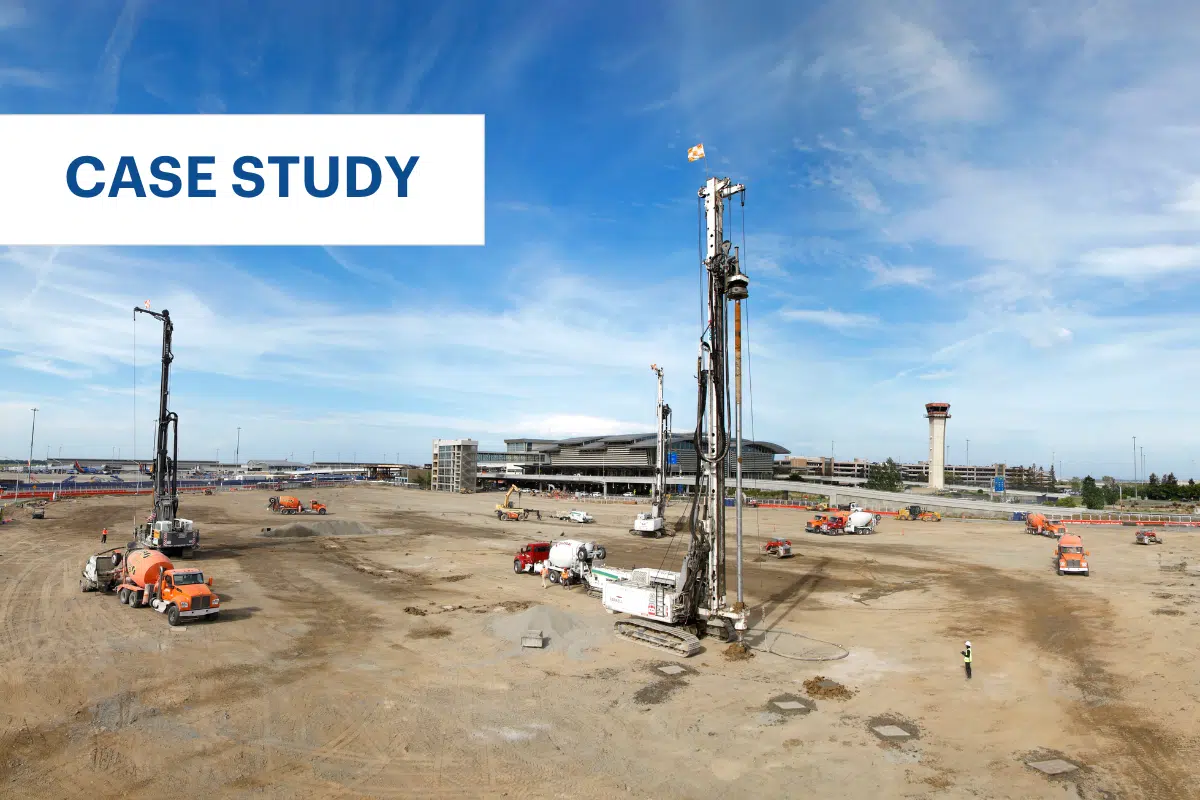

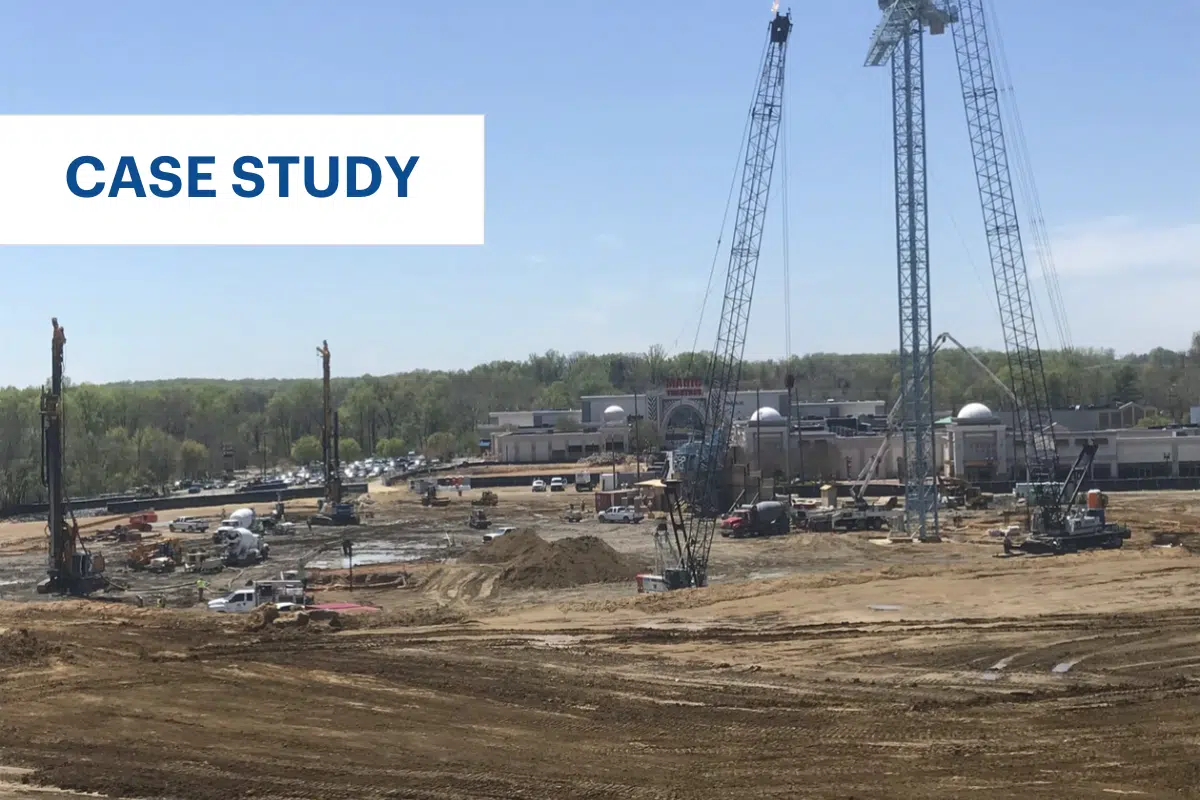

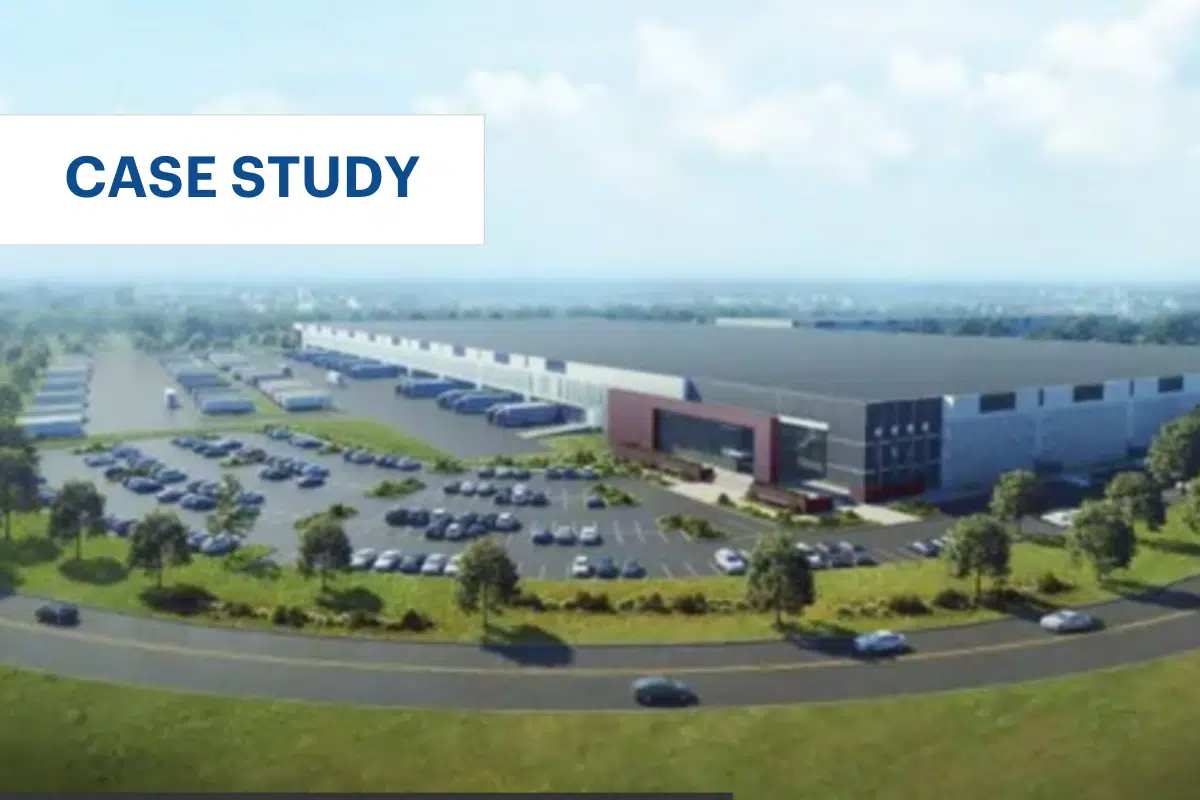

Russo Development and Forsgate Industrial Partners purchased the Kingsland Tract, a 718-acre former landfill site spanning Lyndhurst, Rutherford and North Arlington, from the New Jersey Sports and Exposition Authority for $42.5 million. The site would be built into the Kingsland Meadowlands, a logistics and e-commerce development for up to six buildings totaling more than 3 million sq ft of industrial space. The property could potentially include a solar farm and 400 acres of preserved wetlands. The Meadowlands submarket, according to Russo Development CEO Edward Russo, is one of the strongest industrial/warehouse markets in the United States.

As part of a multi-phase building initiative, a one-story, 895,148 sq-ft warehouse was proposed for the site. The facility would feature 40-ft ceilings, 142 dock doors and four drive-in doors. Due to the nature of the soils at the site – which included fill soils to a maximum depth of 30 ft – Menard Group USA was contracted to provide ground improvement. Menard would perform a dynamic compaction test program to treat the landfills and achieve deep ground densification.

Ground Conditions:

Solution:

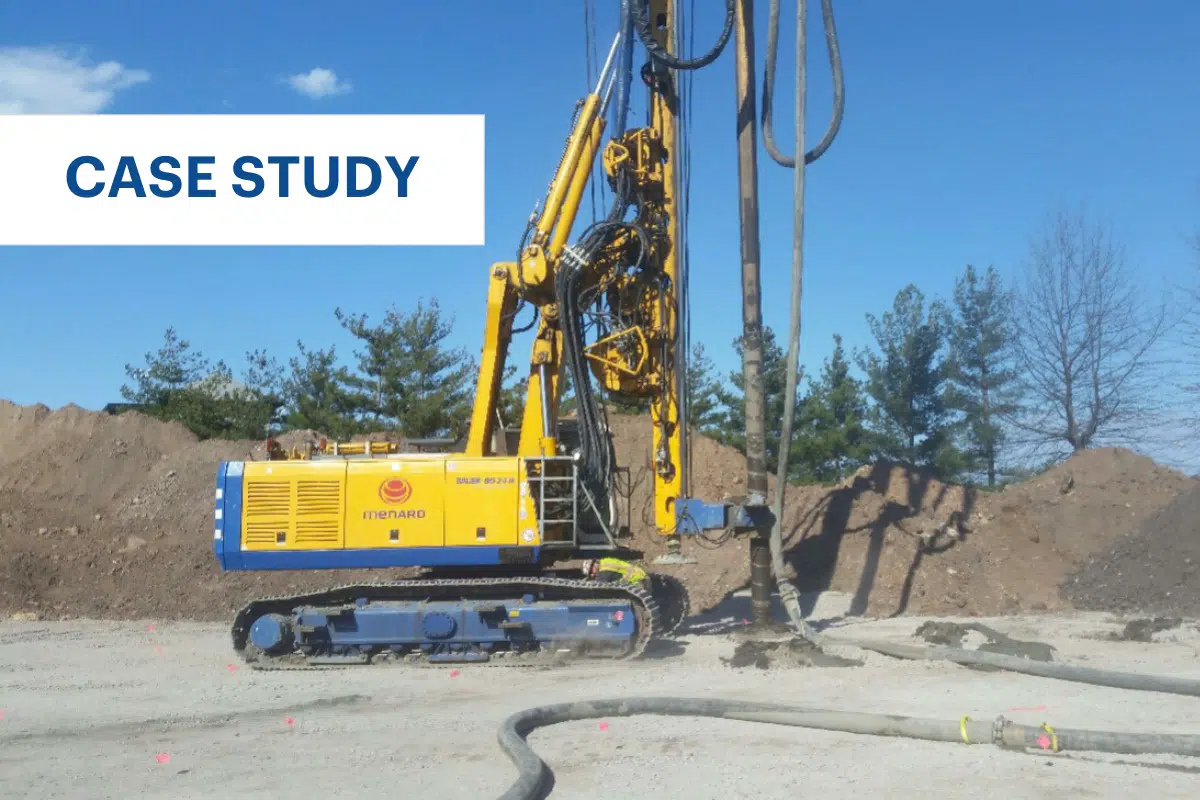

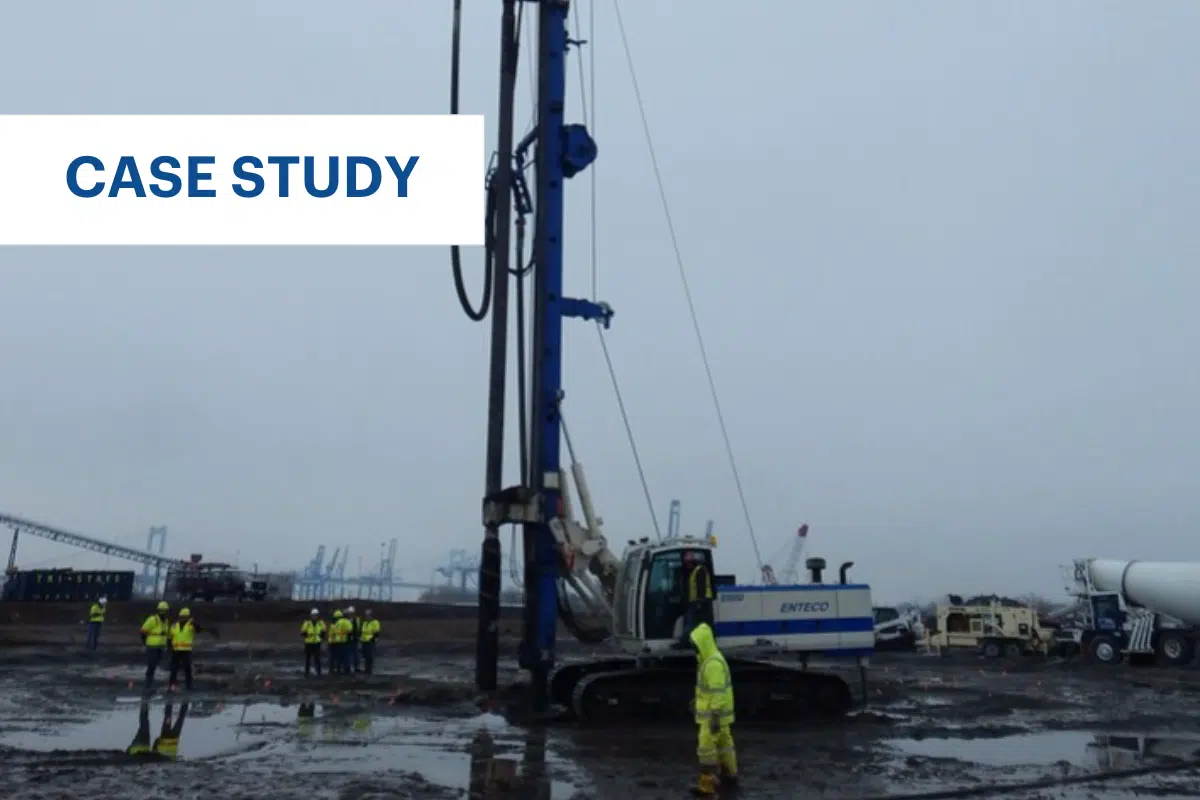

The dynamic compaction approach required 77,962 drops over three phases distributed across the building footprint. The compaction was achieved by using a 20-ton weight dropped from heights of 40, 50 and 65 ft feet to densify the landfill material through the generation of high-energy waves. Treatment depth was 30 ft.

Specifications for the project required a minimum of total allowable bearing slab pressure of 800 psf. The maximum column load for the spread footings was 100 kips. This is the largest dynamic compaction project performed by Menard in New Jersey to date.

To support the construction of an 895,148 sq-ft warehouse in New Jersey, Menard Group USA utilized a dynamic compaction approach to treat landfill material and achieve ground densification.

Print this resource