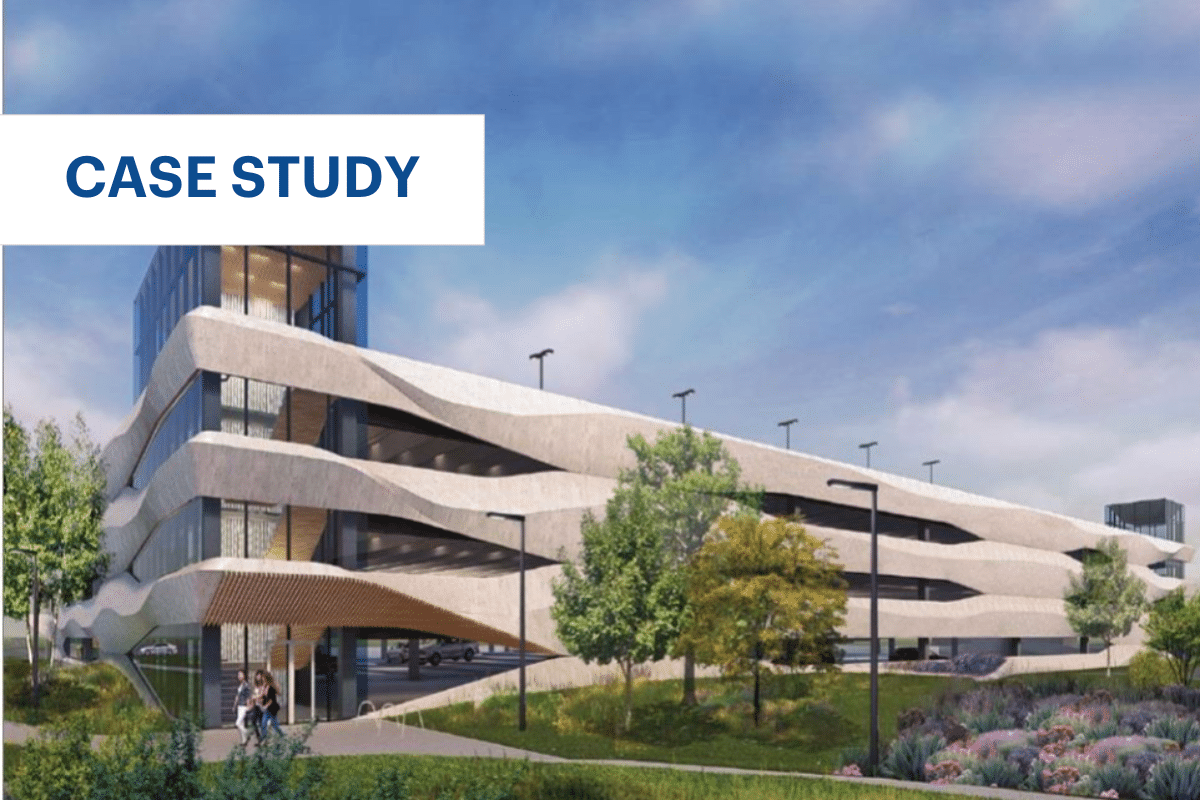

Locks Tower

Locks Tower

Project Details:

Owner: North Falls, LLC

General Contractor: KBS

Date of Work: March 2018 - April 2018

Engineer: Speight - Marshall - Francis

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 353 EA.

Description:

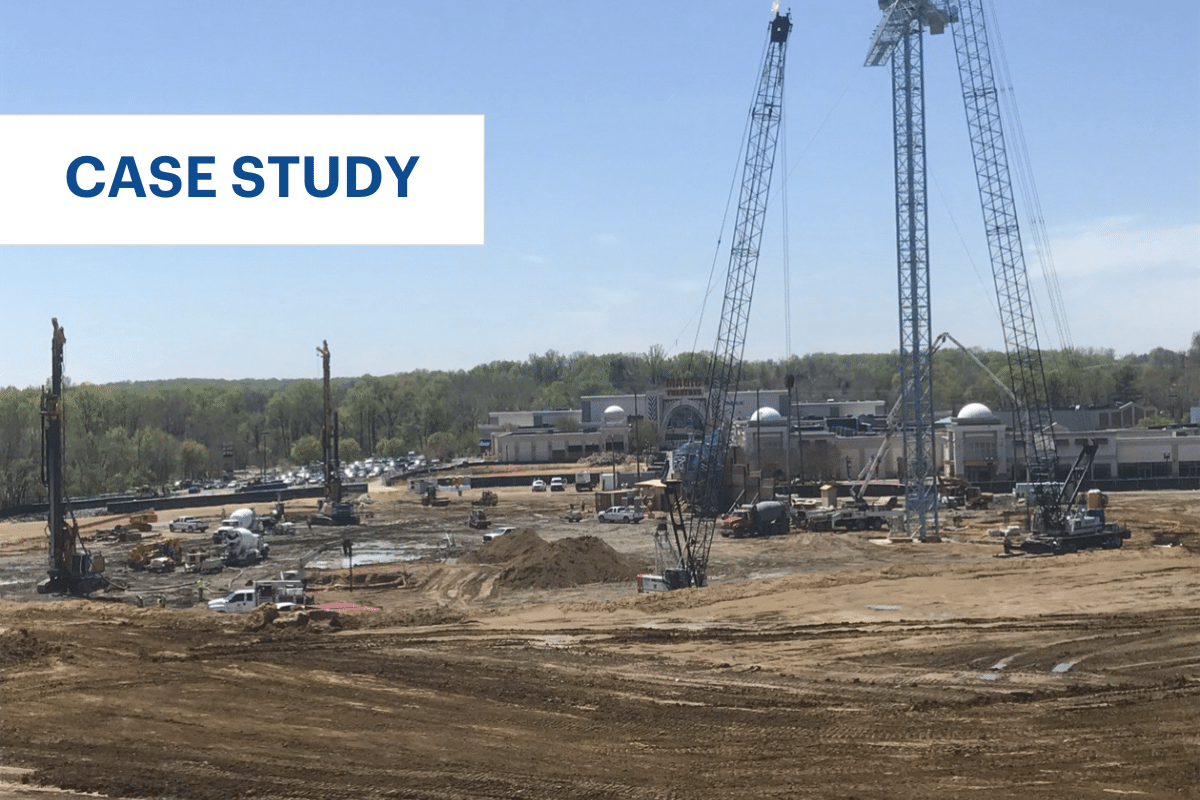

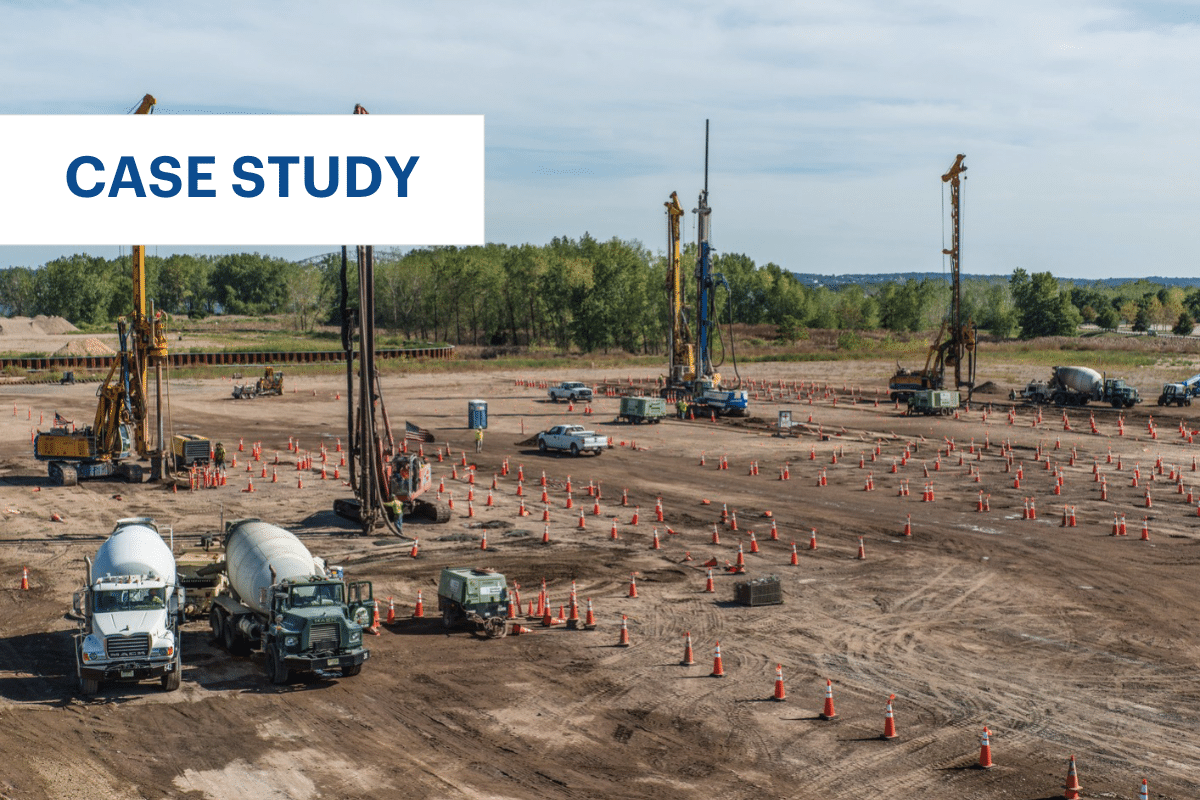

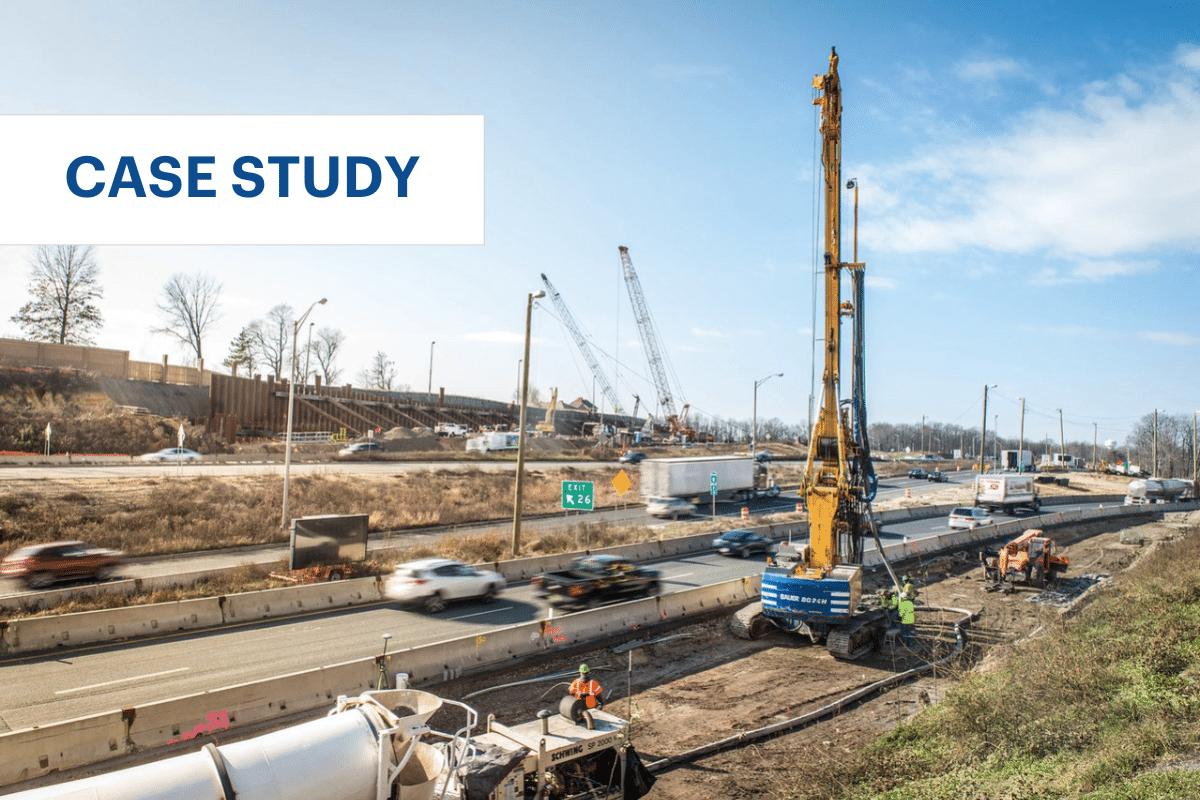

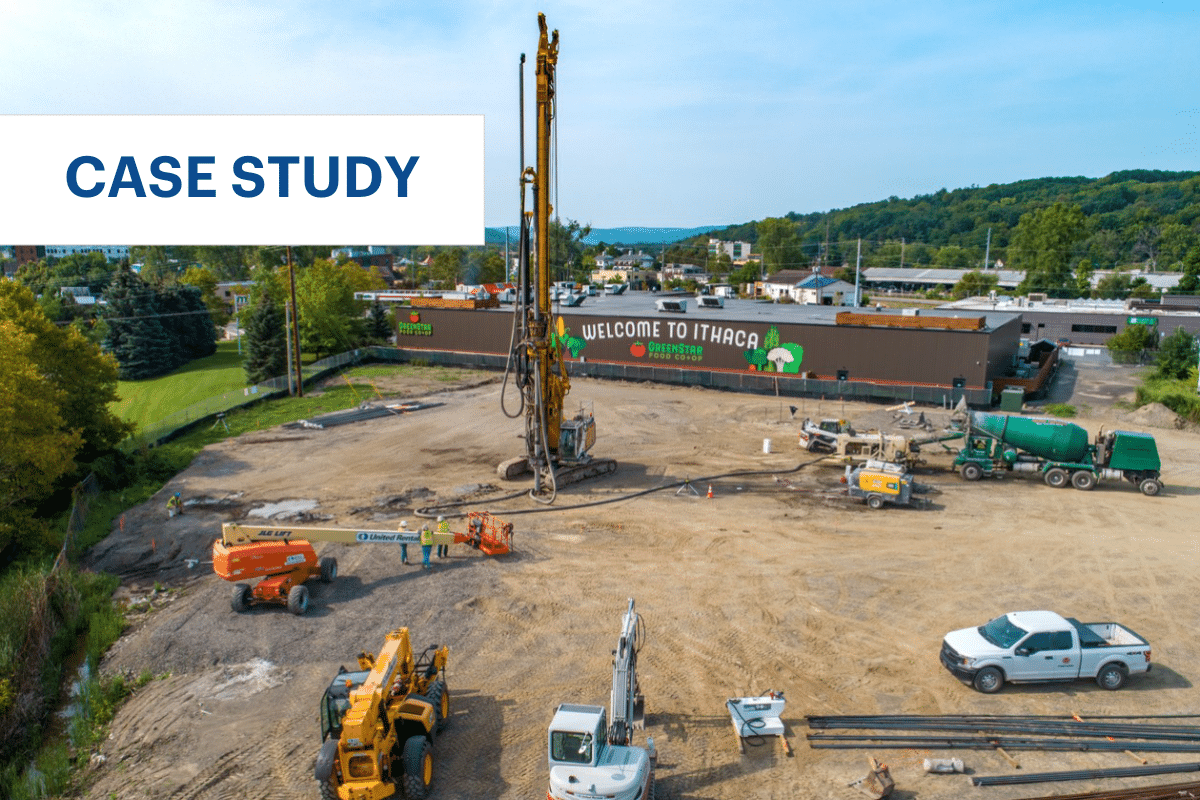

In bustling downtown Richmond, North Falls, LLC proposed the construction of a 12-story, 237-unit apartment building and parking garage on a 1.2-acre area between the Locks and Riverfront Plaza. The project would also involve the construction of retaining walls on the north and east side of the site. The ground floor of the building would include 12,000 sq ft of commercial space. The rest of the C-shaped tower would contain one- and two-bedroom apartments.

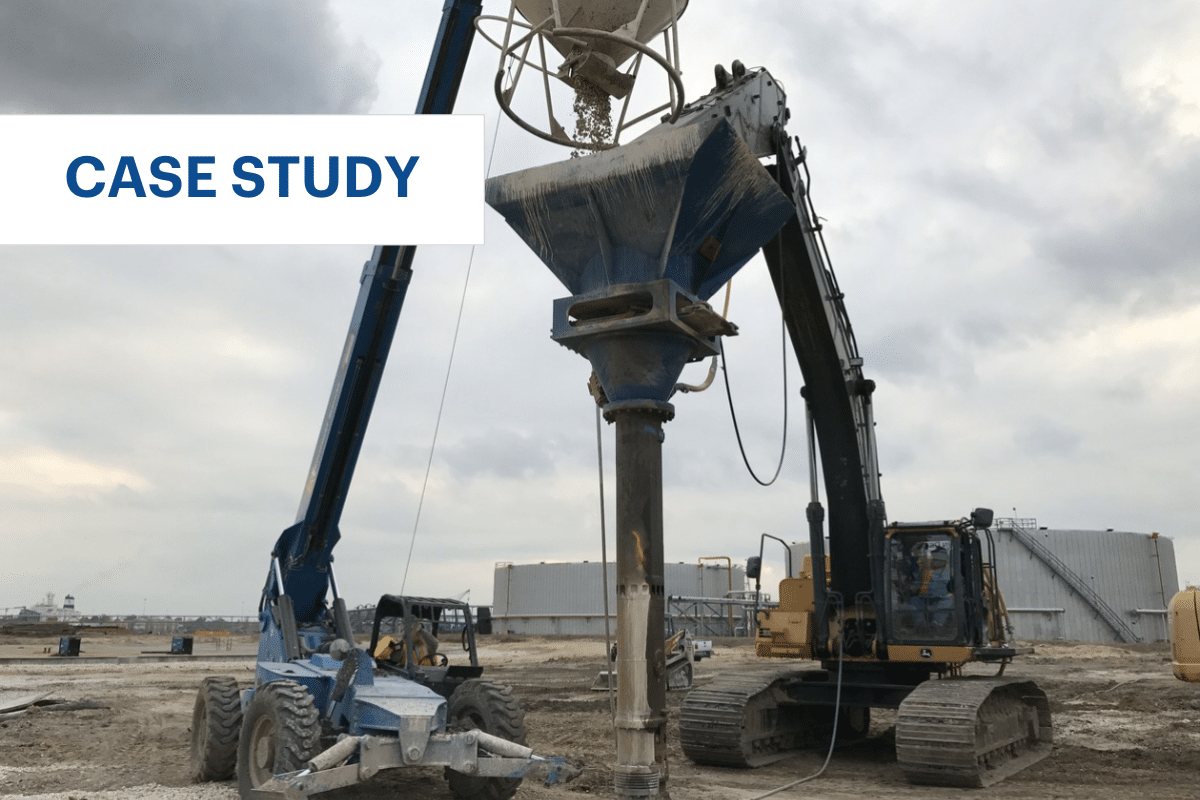

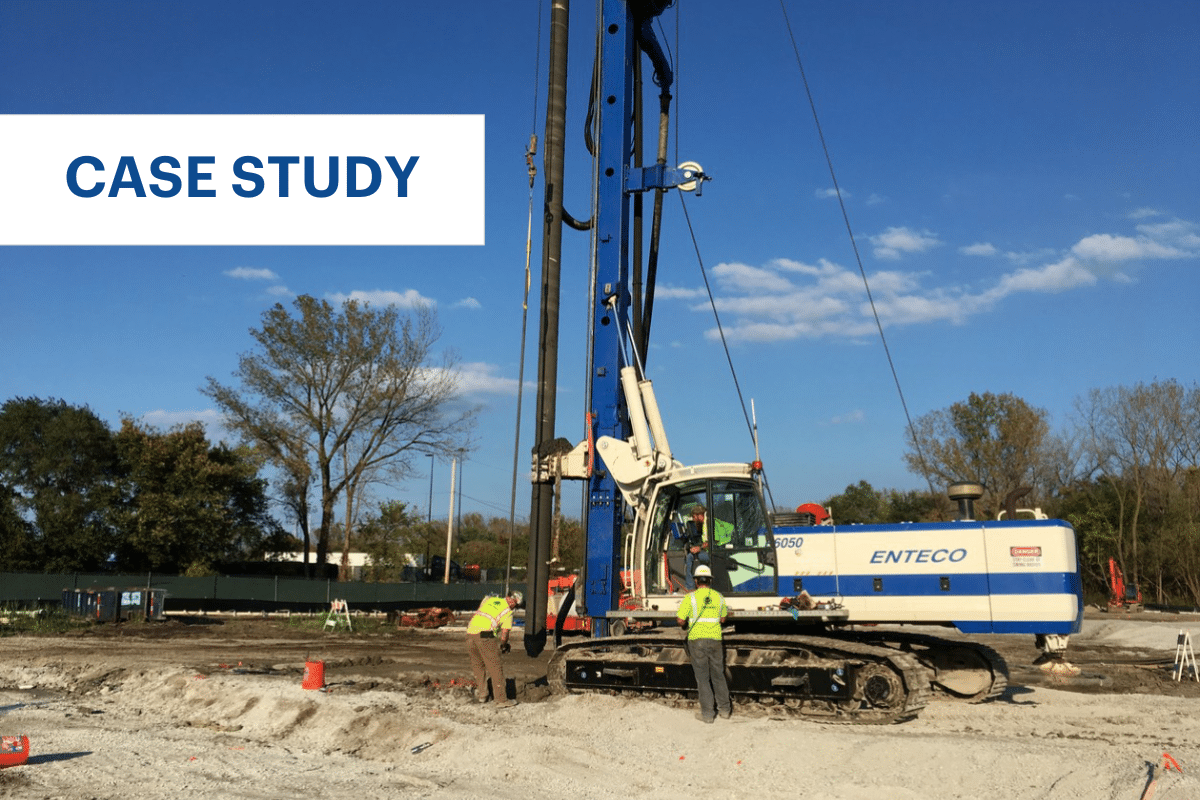

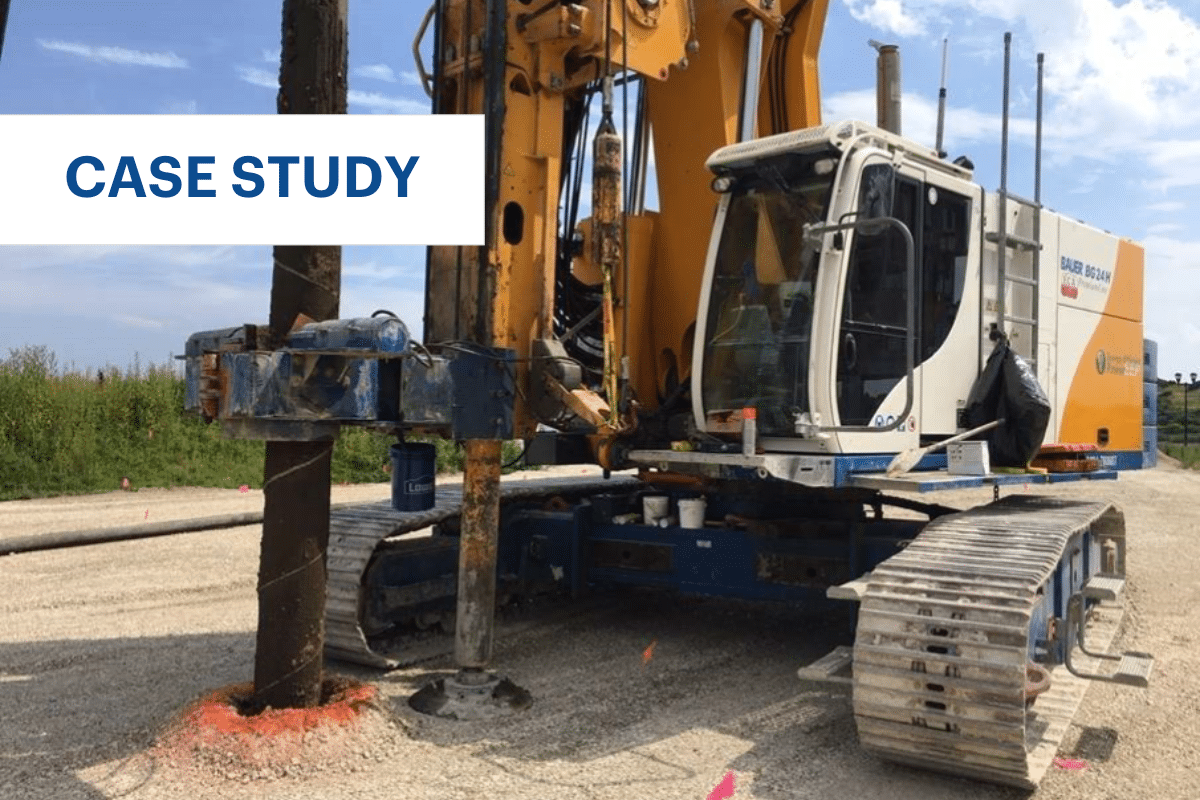

Menard Group USA was contracted to install Controlled Modulus Column (CMC)® rigid inclusions to mitigate ground settlement and to provide suitable bearing under the building footings.

Ground Conditions:

Solution:

To provide suitable bearing for the new development, Menard successfully installed 268 compression CMCs and 88 uplift CMCs below the footings of the Locks Tower apartment complex. The elements were installed at an average depth of 20.6 ft and a maximum depth of 35.4 ft.

The uplift CMCs were designed for account for an overturning moment of the building. The uplift elements, which featured specialized sleeves, applied upward force exclusively to the bottom of the CMCs, rather than applying force throughout. By using CMCs in lieu of piles or excavation and replacement methods, Menard provided a cost-effective and time-saving solution for the client.

Moreover, because the work was performed in a downtown setting adjacent to a number of structures, the installation of CMCs provided a less-disruptive solution than piles. Work was completed in 11.5 days, well ahead of the four-week schedule. All work met the client’s requirements for quality and safety.

Print this resource