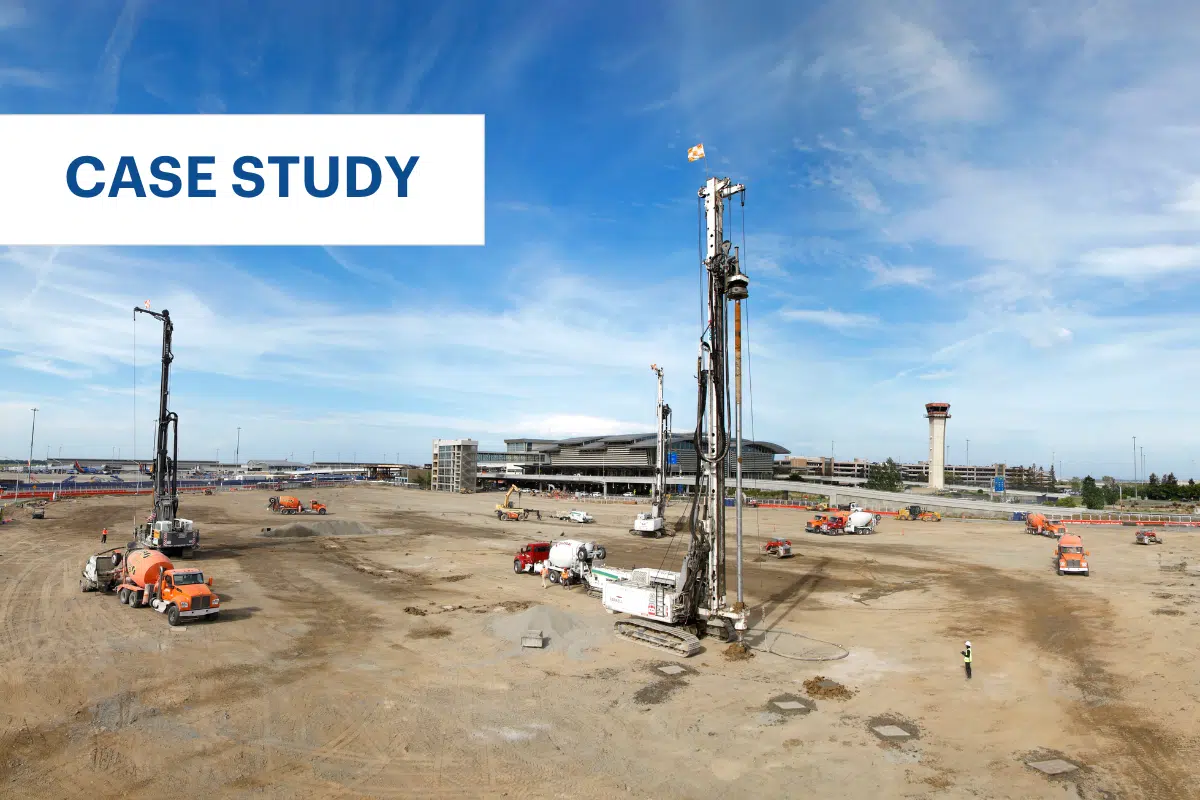

Prologis Elizabeth Seaport

Prologis Elizabeth Seaport

Project Details:

Owner: Prologis, L.P.

General Contractor: RC Andersen

Date of Work: July 2015 - December 2015

Engineer: Melick-Tully

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 8,900 EA. & Dynamic Compaction (50 drops - 13.5-ton weight dropped from 50 feet)

Description:

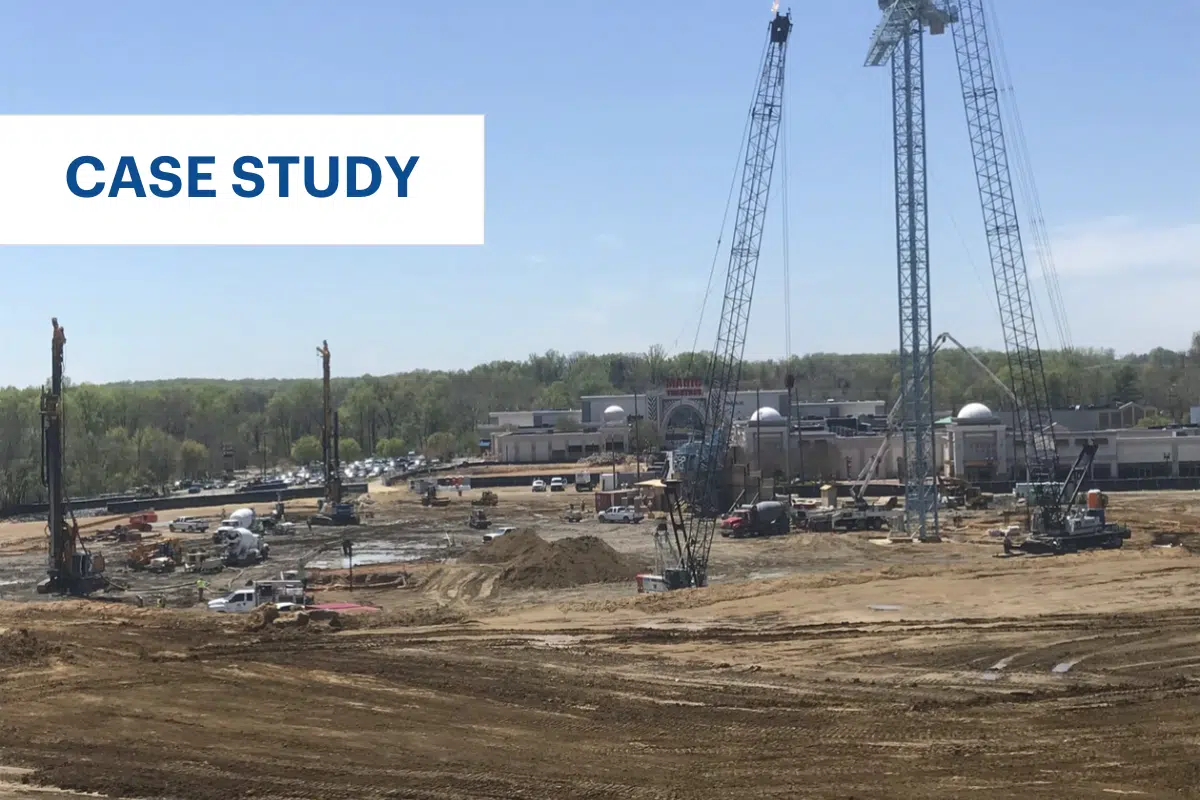

Prologis, L.P., a global leader in industrial real estate, required a ground improvement solution to support two new logistics warehouses located in Elizabeth, NJ. Menard Group USA installed Controlled Modulus Column (CMC)ᵀᴹ rigid inclusions to support the footings and slab on grade for the sites of the two warehouses: Building A at 500,000 sq ft and Building B at 200,000 sq ft.

This solution was chosen as an economical alternative to more traditional foundation solutions, such as driven steel piles with a thick structural slab.

Ground Conditions:

The site selected for Building A consisted of Processed Dredged Material (PDM) and previously unmonitored fill for the upper 25 ft. The PDM layer was underlain by organic peat from about 25 to 31 ft, underlain by a layer of dense sand from 31 to 45 ft.

The soil profiles for Buildings A and B were similar except that the PDM layer at Building A was more compact than at Building B.

Solution:

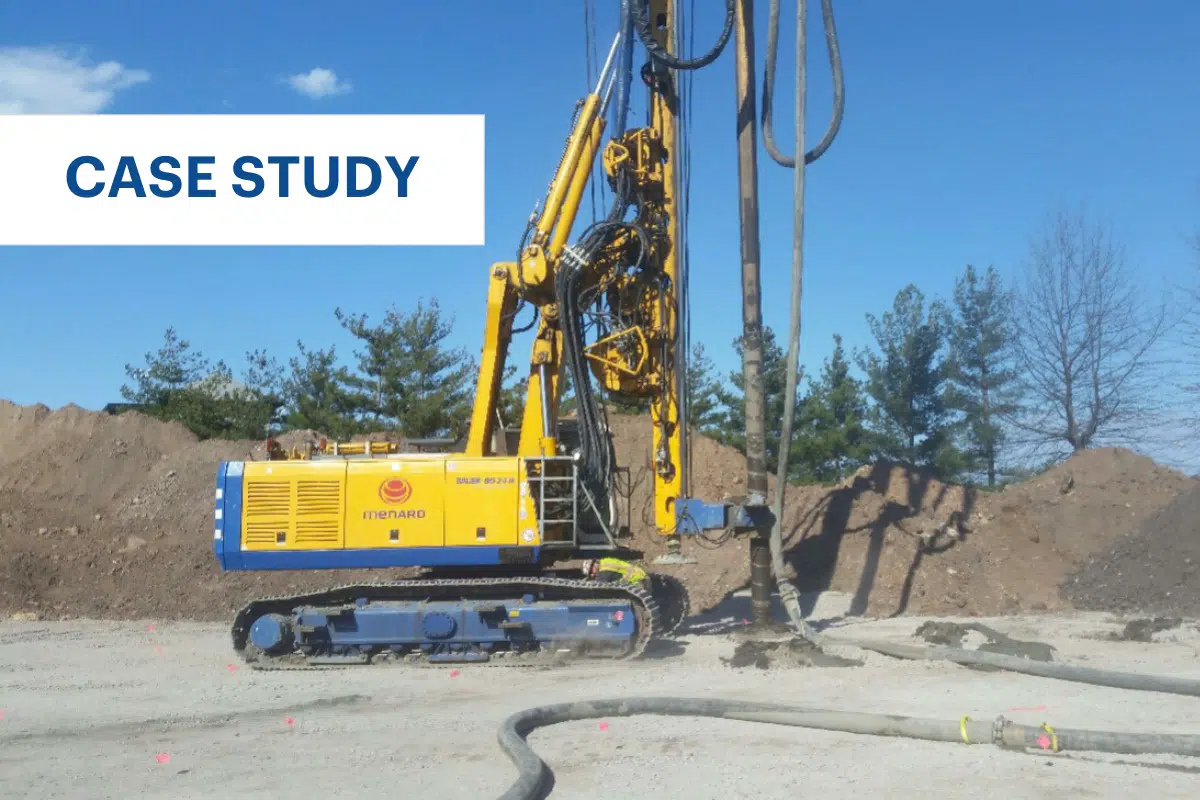

Menard's CMC rigid inclusions were chosen as an alternative to a more traditional foundation solution of driven steel piles, because it was more cost-effective and reduced hard points in the slab. A total of 8,900 CMC rigid inclusions were installed to average depths of about 40 ft across both warehouses.

To keep on the client’s schedule, five rigs were utilized on site. Two rigs for pre-drilling, two rigs for CMC rigid inclusion installation, and one rig for both pre-drilling & CMC installation. Pre-drilling was required to penetrate dense fill layers and obstructions within the fill.

Print this resource