Residence Inn Middleburg

Residence Inn Middleburg

Project Details:

Owner: Bagley AHI, Inc.

General Contractor: Alliance Hospitality, Inc.

Date of Work: March 2017 - April 2017

Engineer: Mannik & Smith Group, Inc.

Approximate Key Quantities: Controlled Modulus Columns (CMC)® - 340 EA. & Wick drains - 212,000 LF

Description:

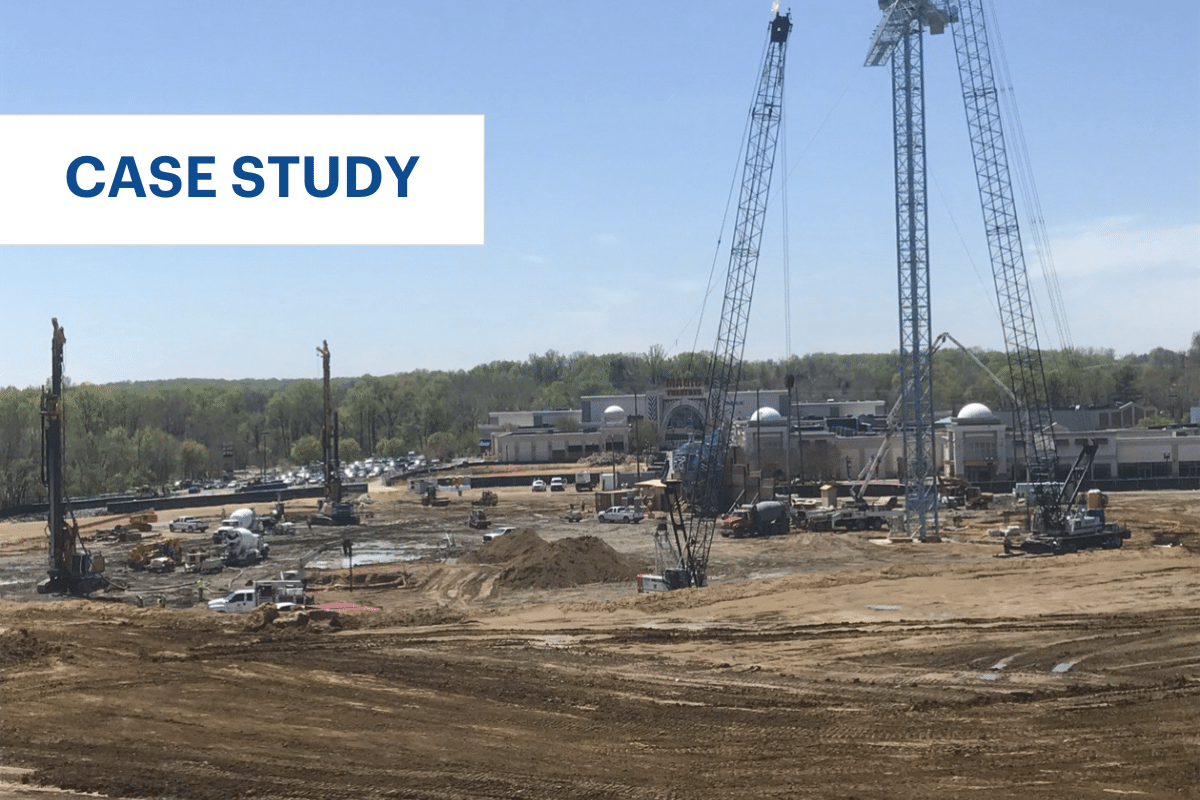

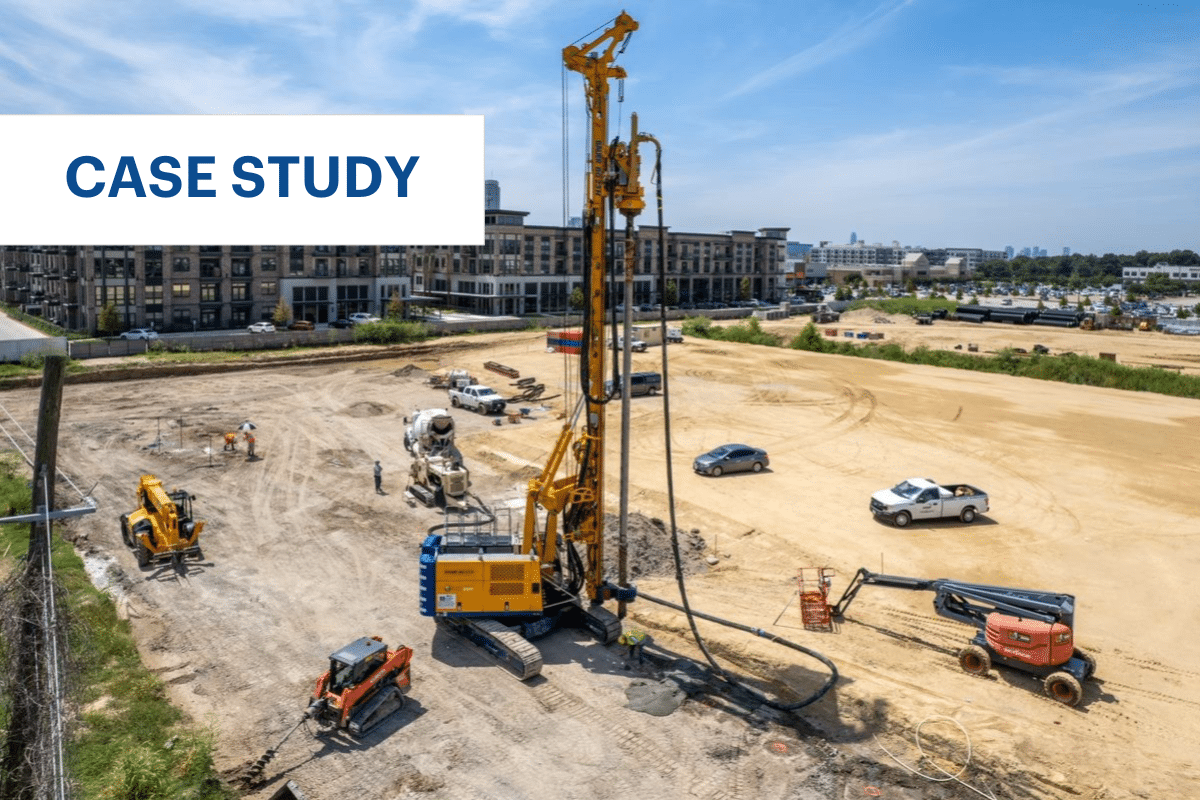

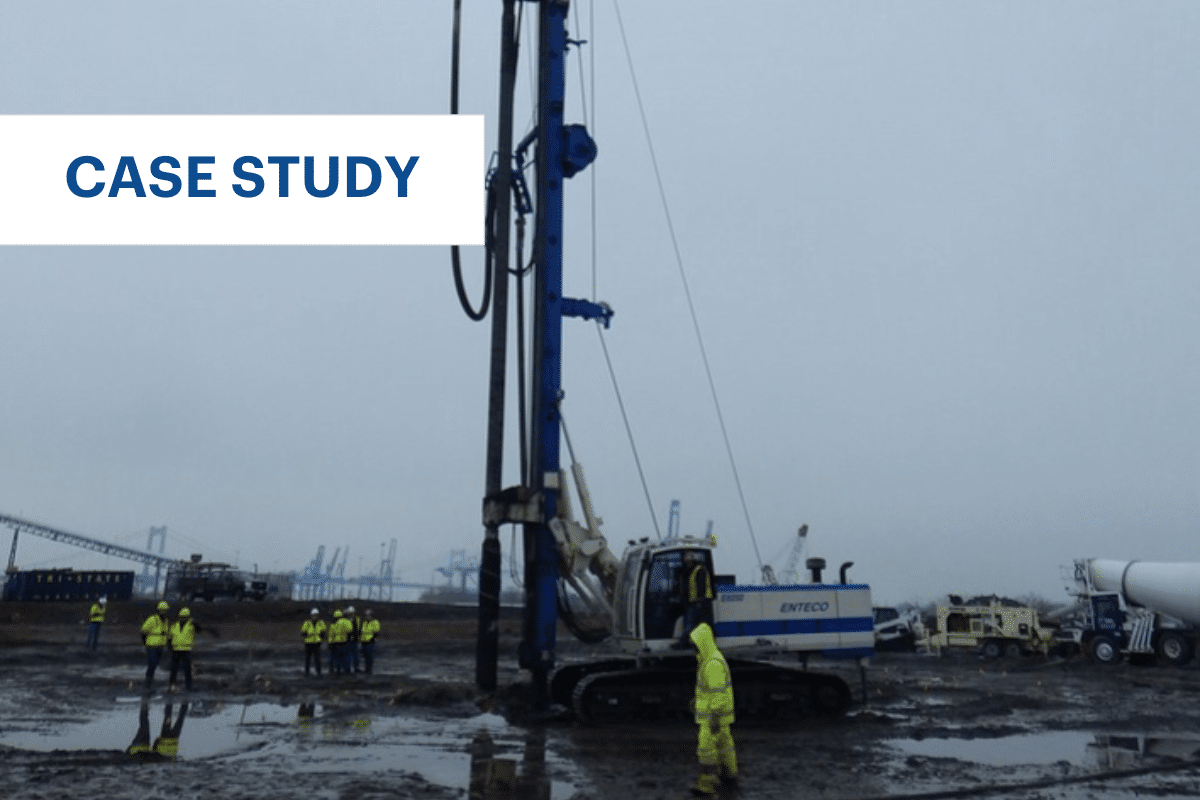

To accommodate an increasing number of visitors to the Greater Cleveland area, the planning commission of the city of Middleburg Heights, OH, approved the construction of a Residence Inn by Marriott hotel. The 167,500 sq-ft site of the future hotel, parking lot, and separate retail building comprises very soft, compressible soils.

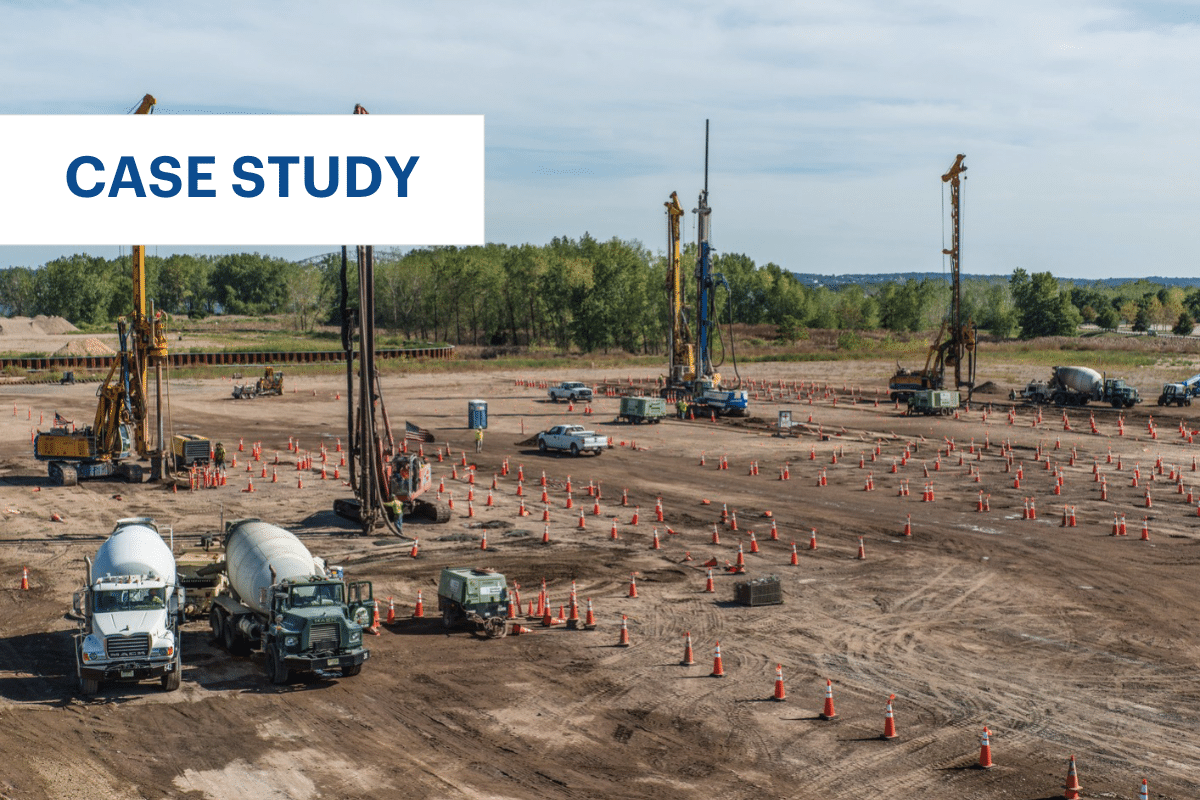

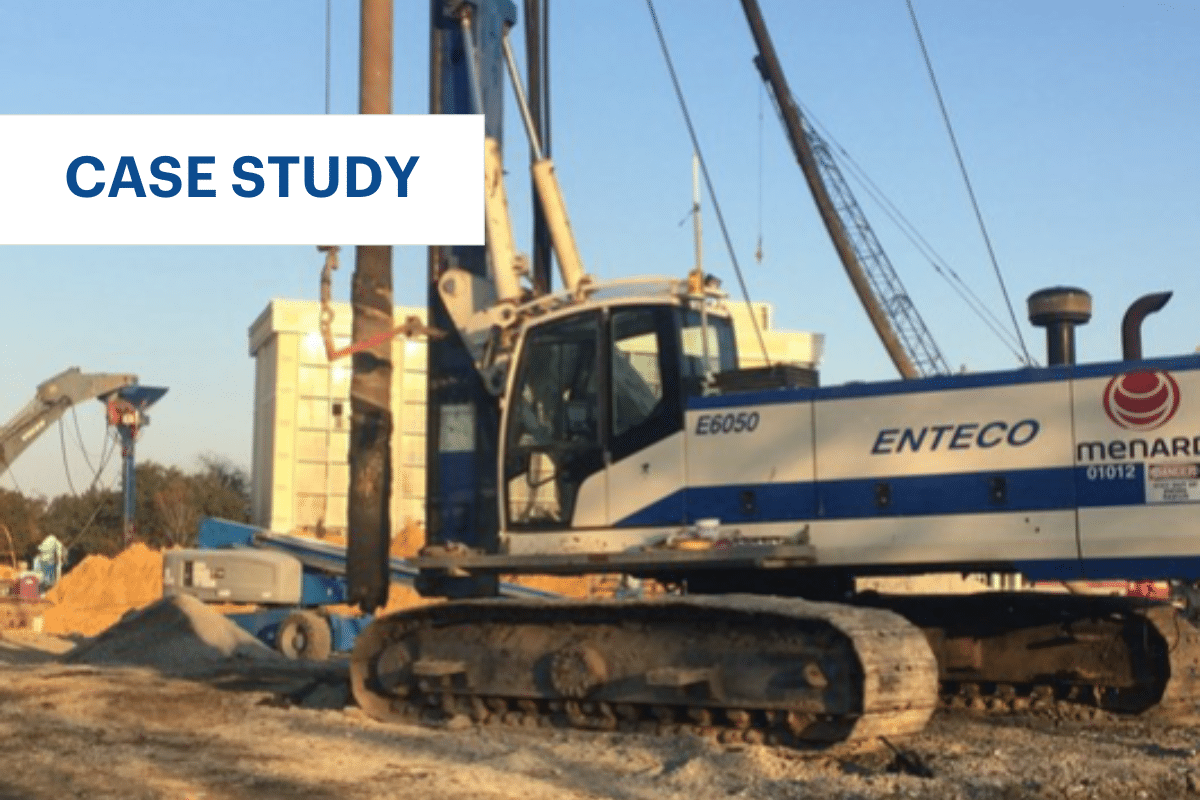

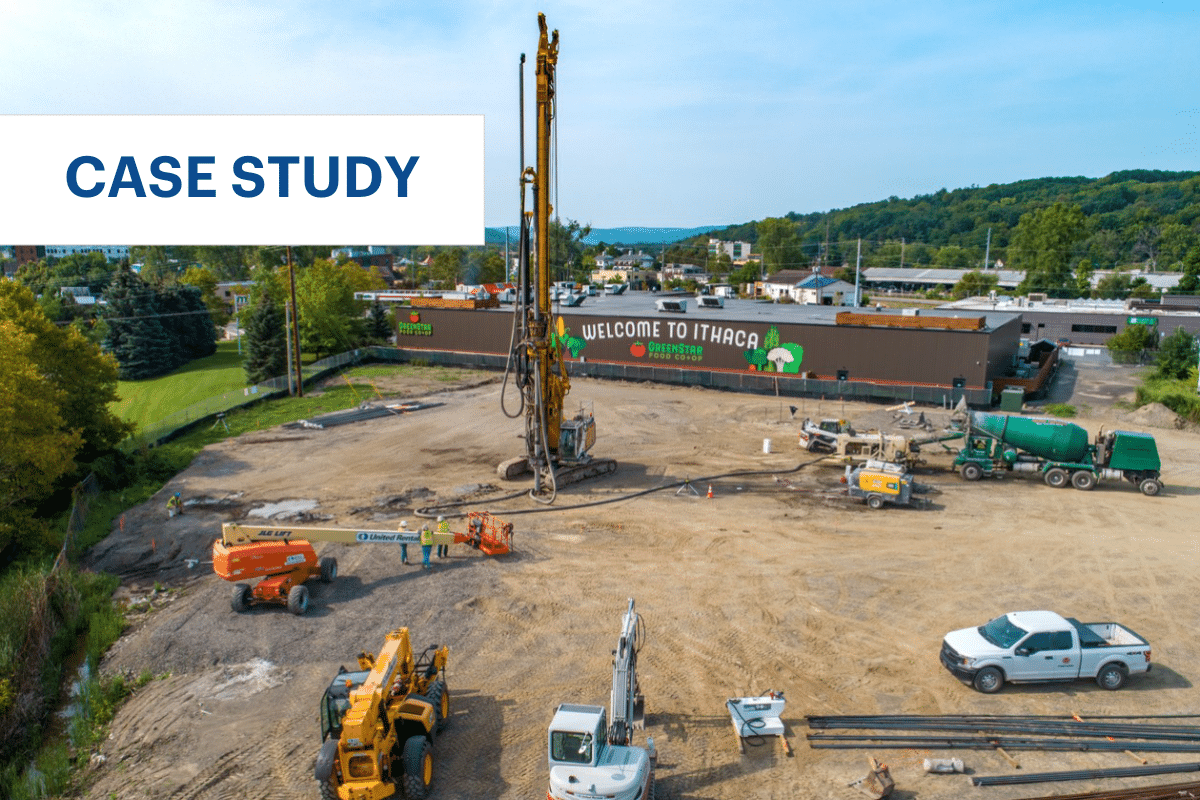

To improve bearing capacity, expedite soil consolidation, and support the new structures, Menard designed a solution utilizing two of its ground improvement techniques: Wick drains and Controlled Modulus Column (CMC)® rigid inclusions.

Ground Conditions:

Site soils are comprised of up to 43 ft of compressible clay, with a 10 ft thick peat layer approximately 15 ft below the surface. This clay layer is overlying dense sands and very stiff clays.

Solution:

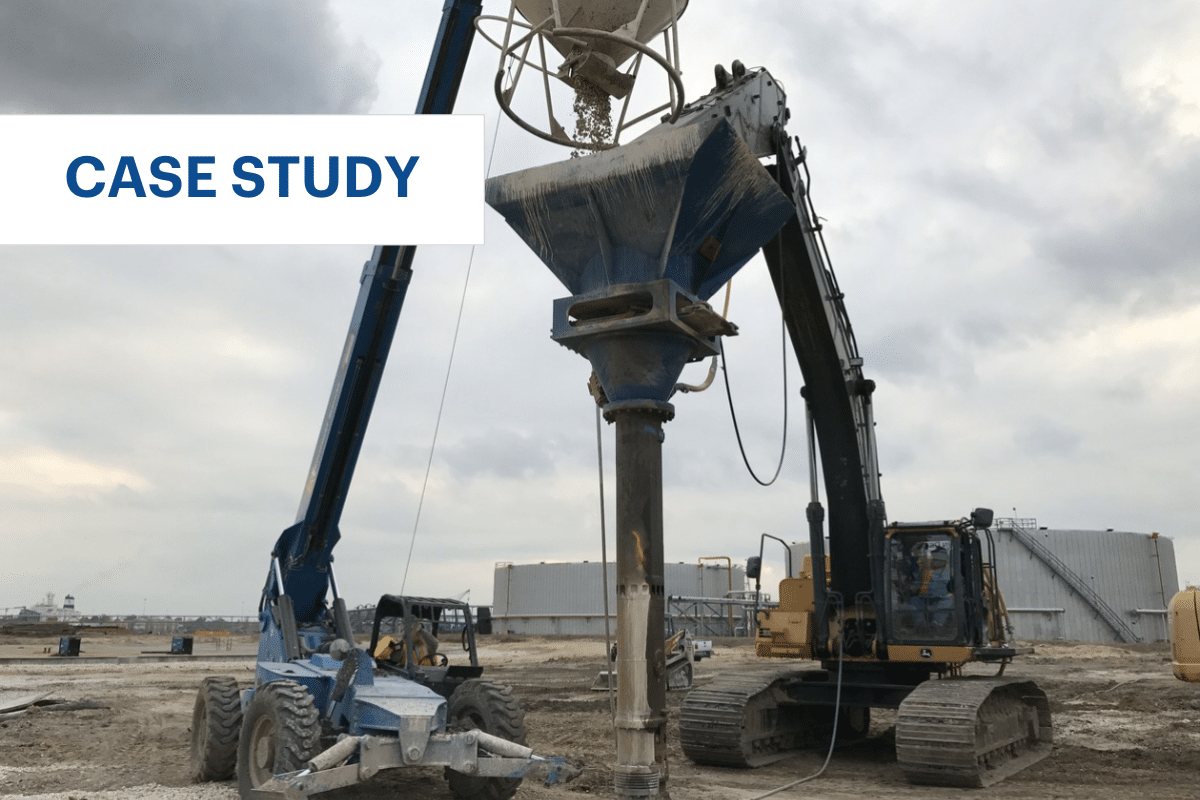

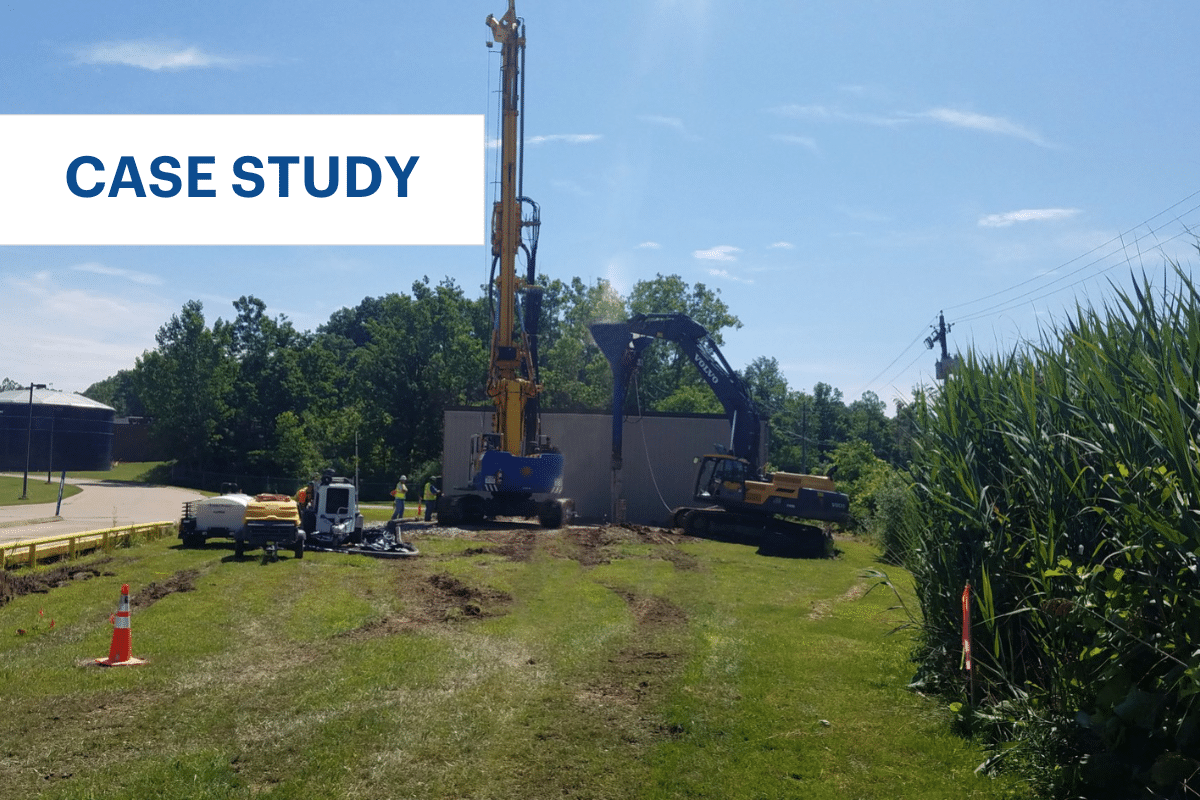

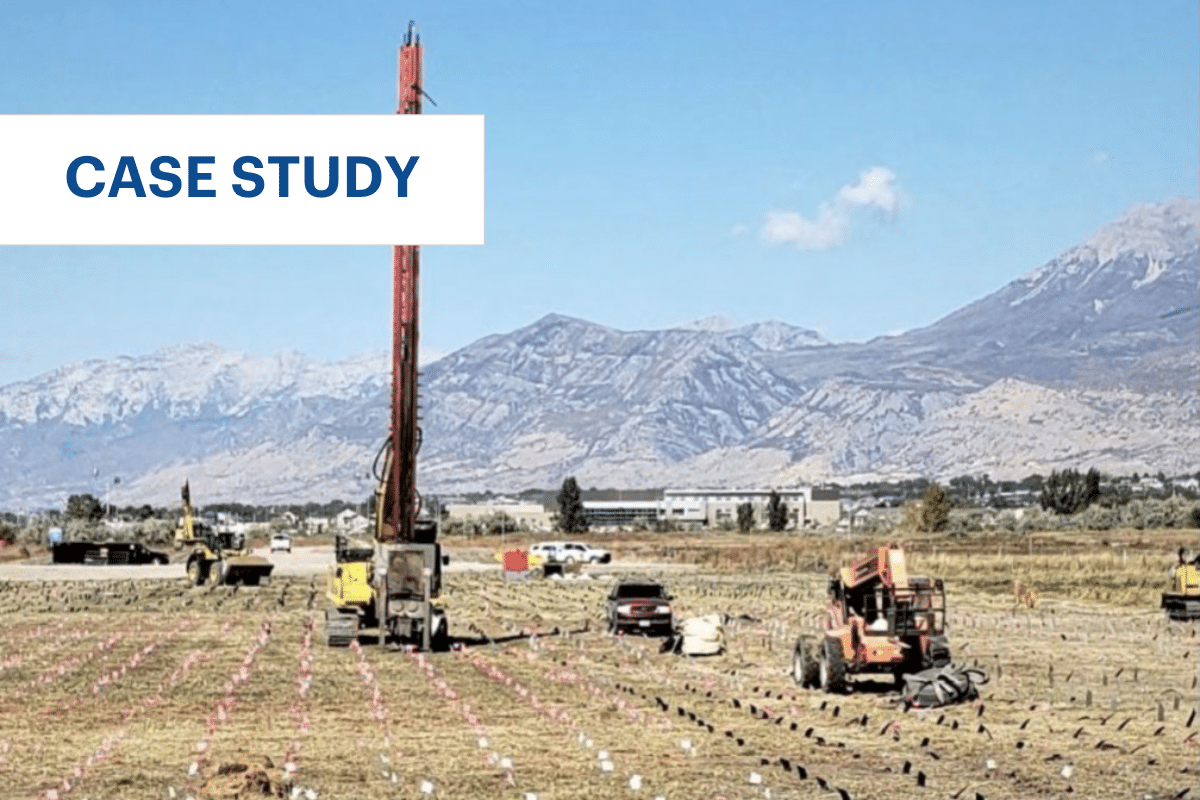

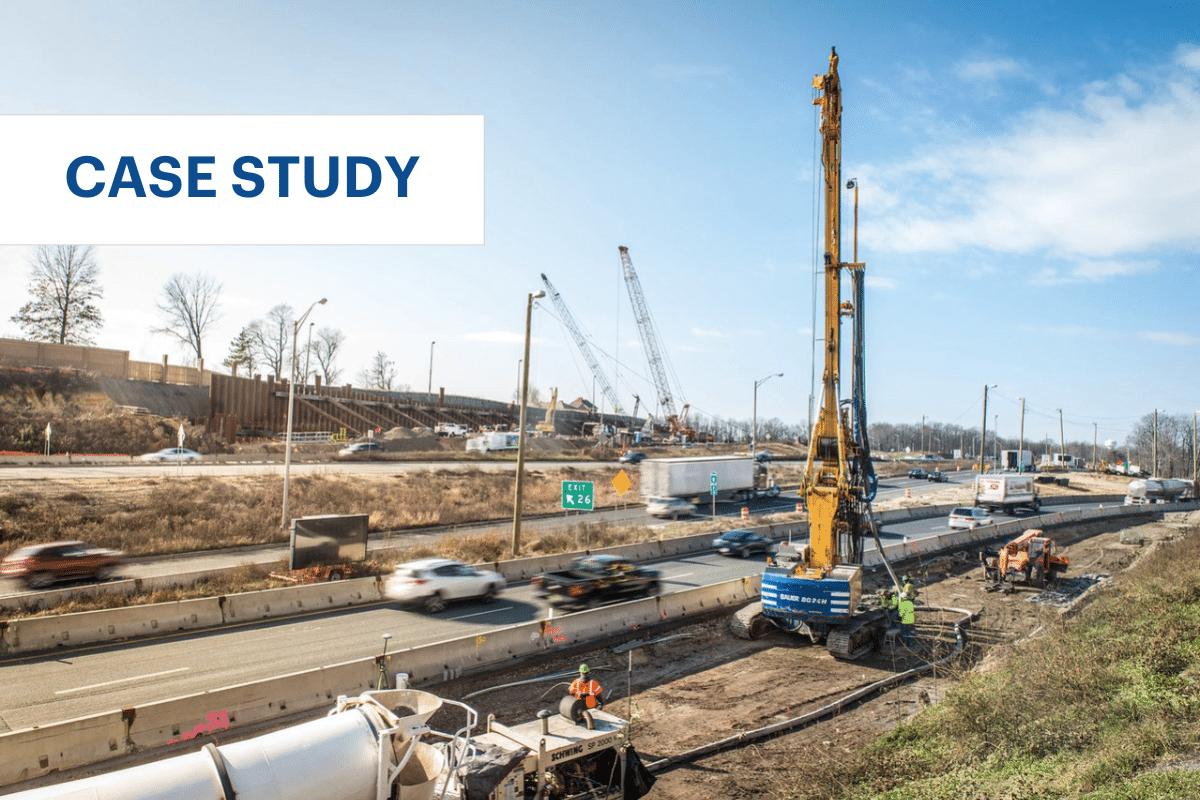

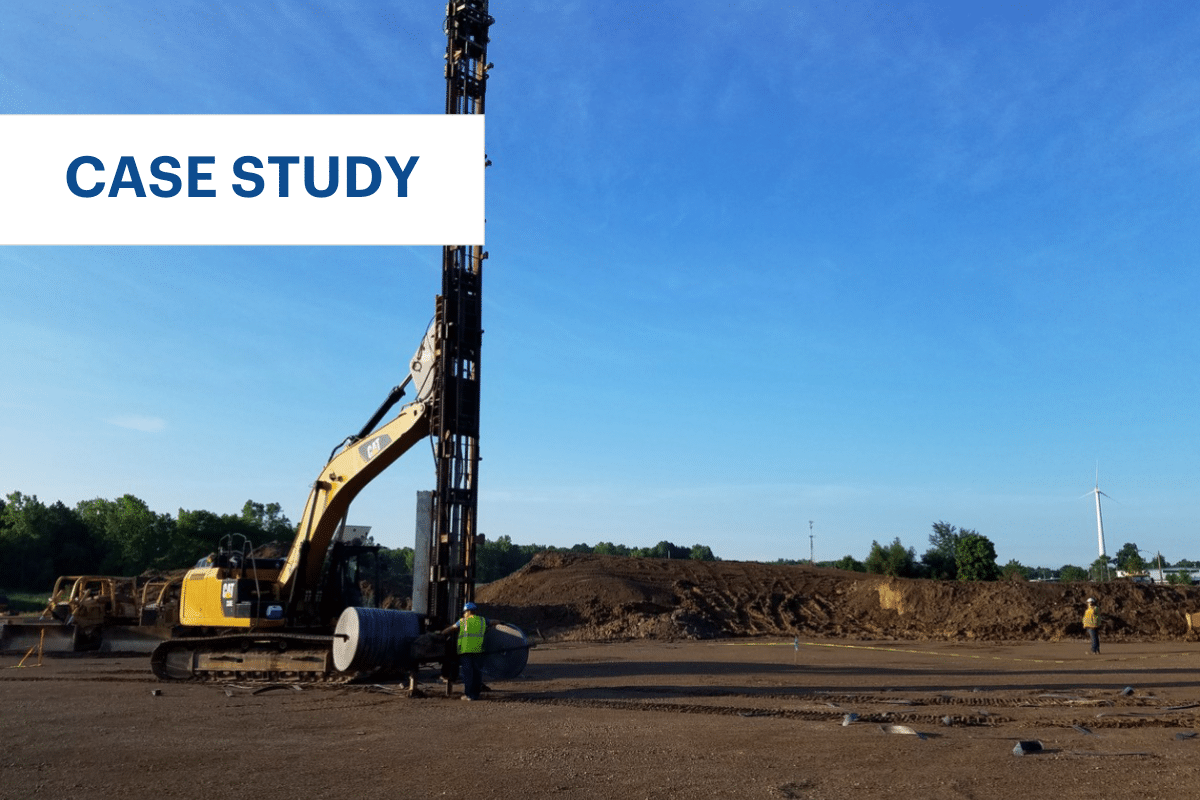

Menard crews first installed wick drains across the entire site. Each wick drain was given an additional 3 ft of ‘stick up’ above the ground surface so it could be attached to strip drains running along every other row. Strip drains are useful for directing water away from the job site as it is conveyed to the surface by the wick drains. The water was then deposited into a nearby wetland.

Seven months was allocated between wick drain installation and CMC rigid inclusion installation to allow for desired settlement. The wick drain-improved soil in proximity to the wetland experienced the most settlement of approximately 3 to 5 ft. The site was then regraded to the initial working pad elevation for the upcoming CMC rigid inclusion installation.

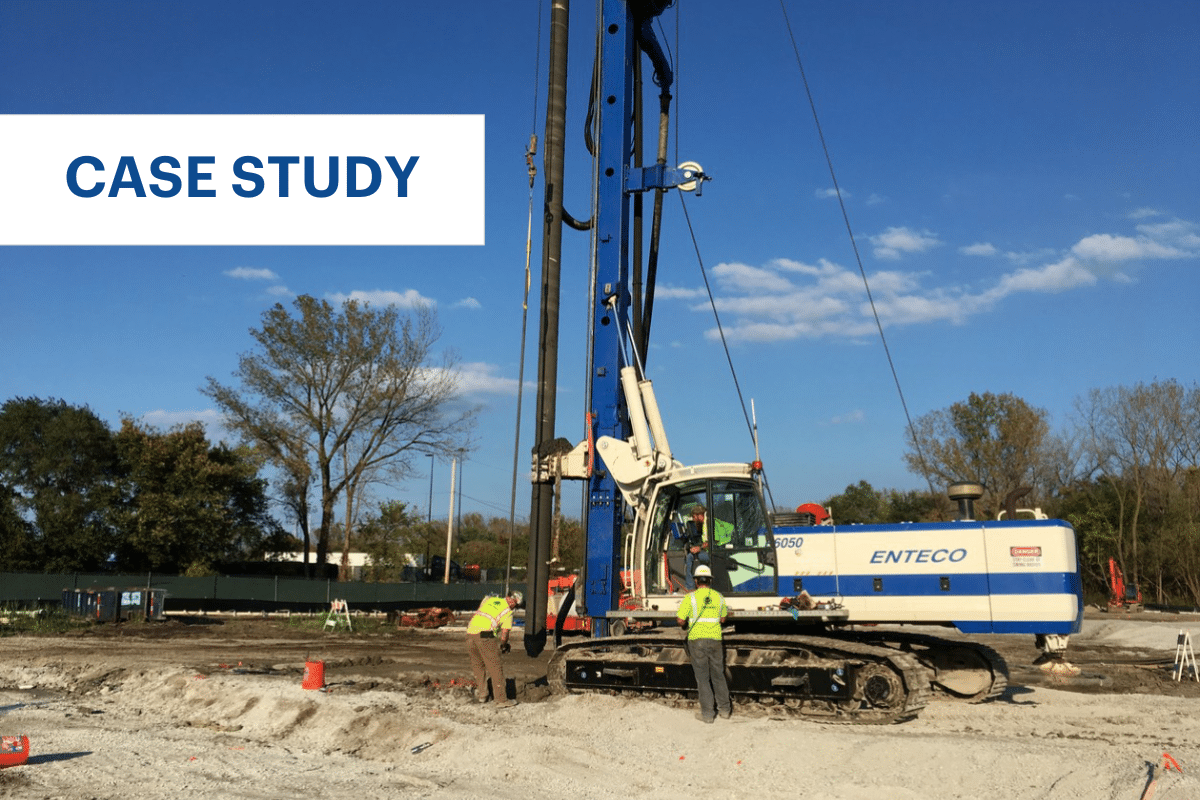

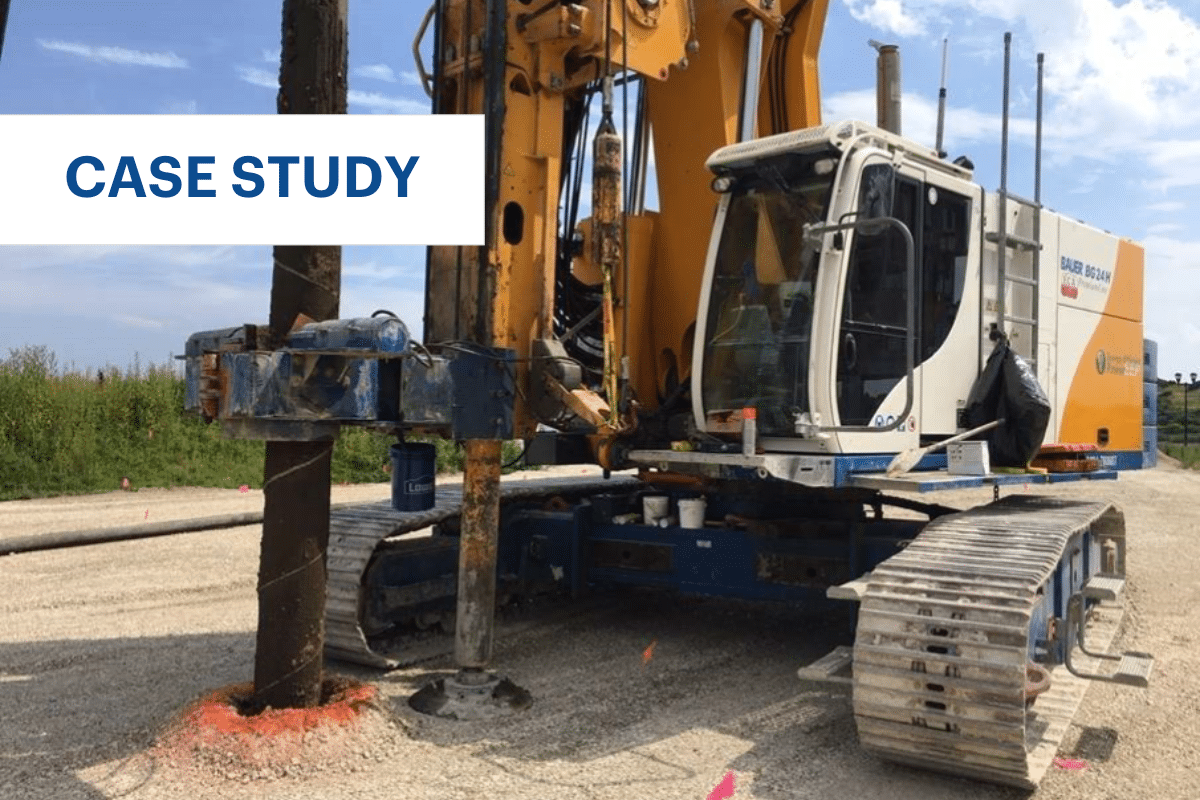

CMC rigid inclusions were installed on the site of the future hotel structure, an approximately 90,000 sq-ft area, to support the foundation and footings. Installation of these elements went smoothly and quickly.

A total of 212,000 LF of wick drains were installed to maximum depths of approximately 48 ft, and a total of 340 CMC rigid inclusions were installed to maximum depths of 45 ft.

Print this resource