SONO Development

SONO Development

Project Details:

Owner: Callahan Ward

General Contractor: Callahan Ward

Date of Work: August 2019

Engineer: Whitestone Associates, Inc.

Approximate Key Quantities: Stone columns - 298 EA.

Description:

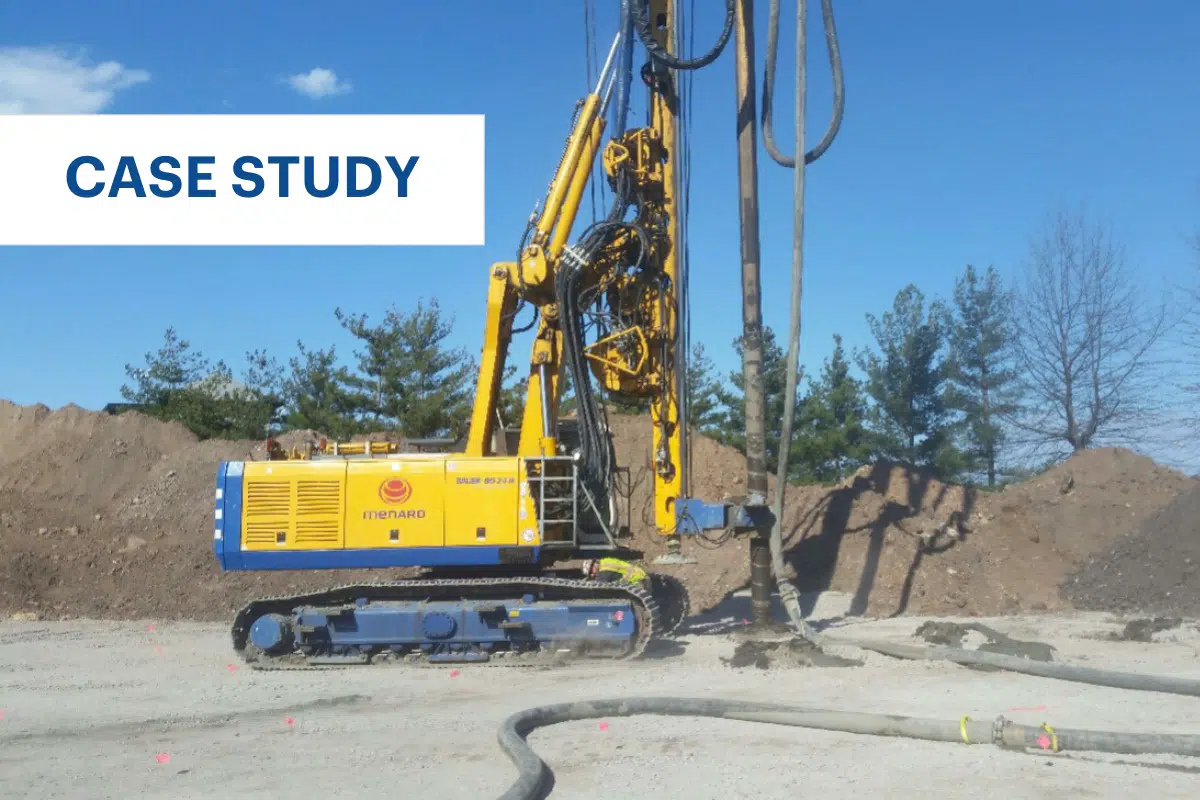

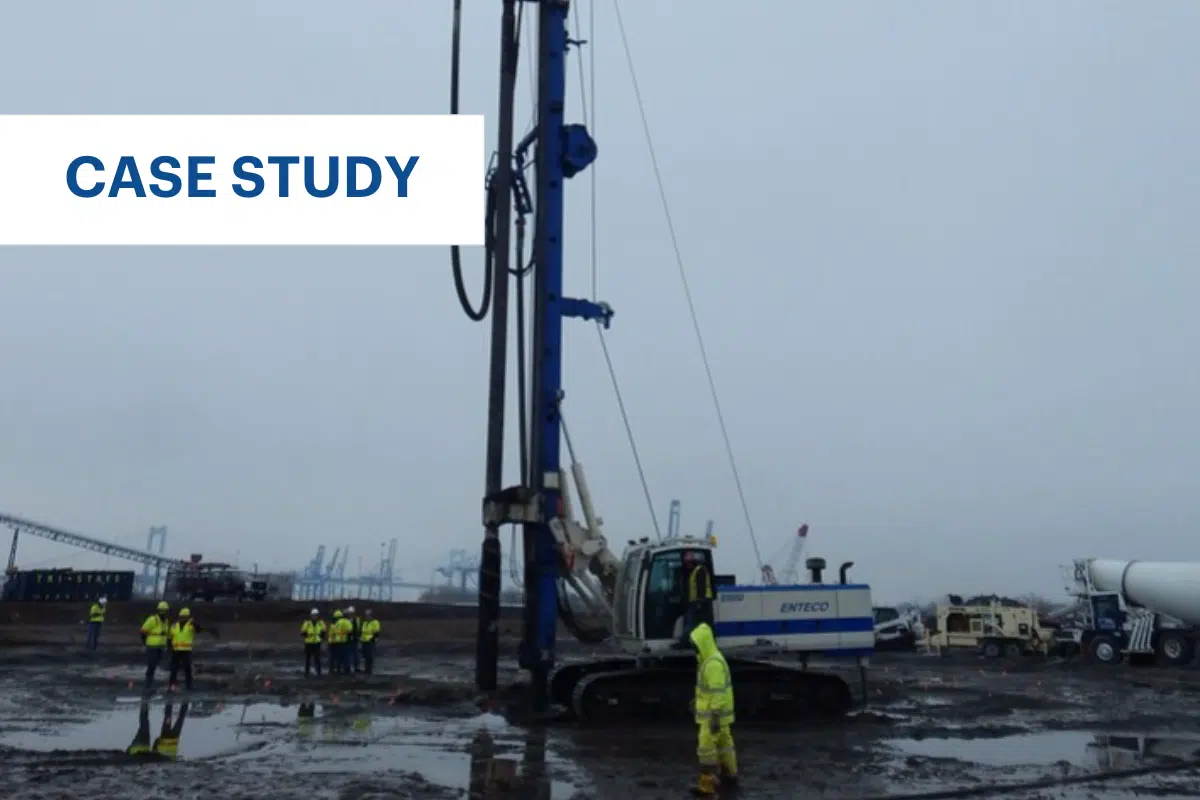

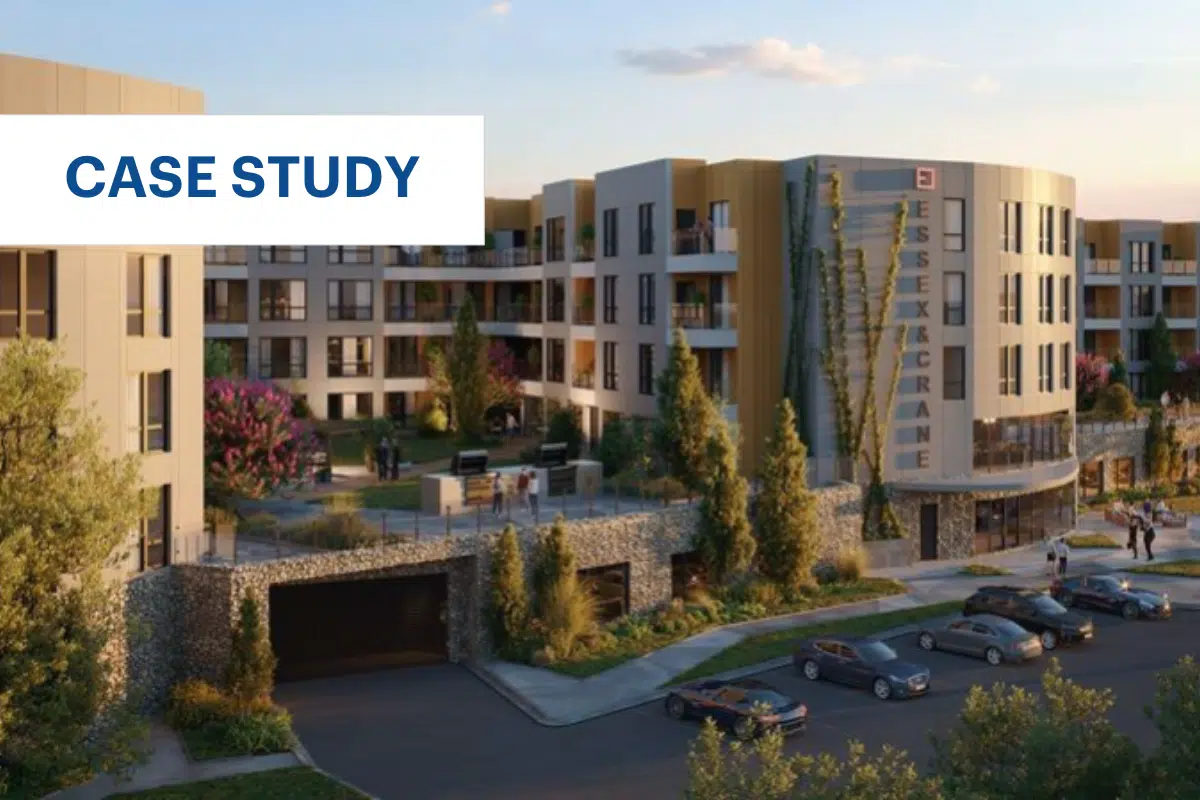

A $60 million project called SoNo – “South of North Liberties” – was proposed for the areas between Northern Liberties and Old City in Philadelphia. Described as cutting edge, the massive undertaking would include 260,000 square-ft horizontal creative office space with amenities aimed at attracting a mix of large, medium and small companies working in a creative and collaborative office community environment. Among the proposed amenities is a cafeteria offering healthy food choices to workers, 75 bike parking spots, onsite parking, exercise rooms, a rooftop amenity deck, which would include “club areas” for private meetings and events, and stadium seating for presentations and gathering. The goal is to create a destination rather than an office -- a place to go to work, to think, to collaborate and to create. Formerly a parking lot within the Philadelphia city limits, the site would feature two four-story, 10,000-square- ft buildings replete with commercial shops on the ground floors and residential dwellings above. Due to the highly variable composition and the presence of voids in the fill, Menard Group USA was contracted to provide ground improvement to support the new buildings – the selected technique was Vibro Stone Columns (VSC).

Ground Conditions:

The site consisted of existing pavement and gravel at the surface, underlain by highly variable fill between 6 to 17 ft deep. Beneath the fill materials were alluvial sands, silts and gravels underlain by dense residual silty sands. Weathered rock was encountered below the silty sand. The layer requiring treatment was the existing fill since it presented highly variable densities and consistencies, debris and voids that would cause excessive total and differential settlement.

Solution:

The geotechnical engineer initially recommended Controlled Modulus Column (CMC) Rigid Inclusions due to the large amount of debris in the existing fill layer below the ground surface. In such instances, CMCs provide effective, long-term support. Menard’s team of experts, however, determined, through test pits, that the fill was not as extensive as originally believed, reducing the concern for voids and obstructions. A more cost-effective solution was the use of VSCs. A total of 298 VSCs – 167 in Building 1; 131 in Building 2 – were installed to a maximum depth of 30 ft. Building column loads ranged from 20 to 256 kips, while bearing capacity up to 4 ksf was required for spread footings. The VSC design provided a maximum of 1 in of post-construction settlement with ½-in differential settlement, meeting the performance criteria for the new buildings. Menard advocated for over-excavation in lieu of VCSs for slab support to provide the client with overall savings on foundation costs. Additionally, Menard provided savings in schedule by virtue of efficient mobilization and high production rates. Several challenges were presented during the two-week project. Among them: The site was adjacent to multiple power lines and other overhead obstructions, as well as active urban roadways and sidewalks; the working pad was uneven and required regrading; access to the site was limited and posed a challenge when moving equipment in and out; the Menard operations team shared the confined site area with the earthworks contractor, who was excavating a 10-ft basement adjacent to the VSC locations; some voids were encountered in the fill material during installation. True to its core belief, Menard prioritized safety for its crew, nearby pedestrians, vehicles and on-site subcontractors while installing VSCs adjacent to the basement excavation, overhead obstructions and perimeter fencing. Menard’s tactful rig maneuvering overcame the uneven working pad issues, while open communication with the owner/General Contractor and other subcontractors allowed for effective work in the confined area. Voids that were encountered in the existing fill were filled with aggregate to provide adequate stabilization.

To support the construction of two four-story, 10,000 square-ft buildings as part of a major renovation project in Philadelphia, Menard Group USA installed 298 VSCs. The use of VSCs in lieu of the originally-proposed Rigid Inclusions brought significant time and cost savings to the project.

Print this resource