Unilever Ice Cream Freezer Warehouse

Project Details:

Owner: Unilever

General Contractor: The Whiting-Turner Contractor Company

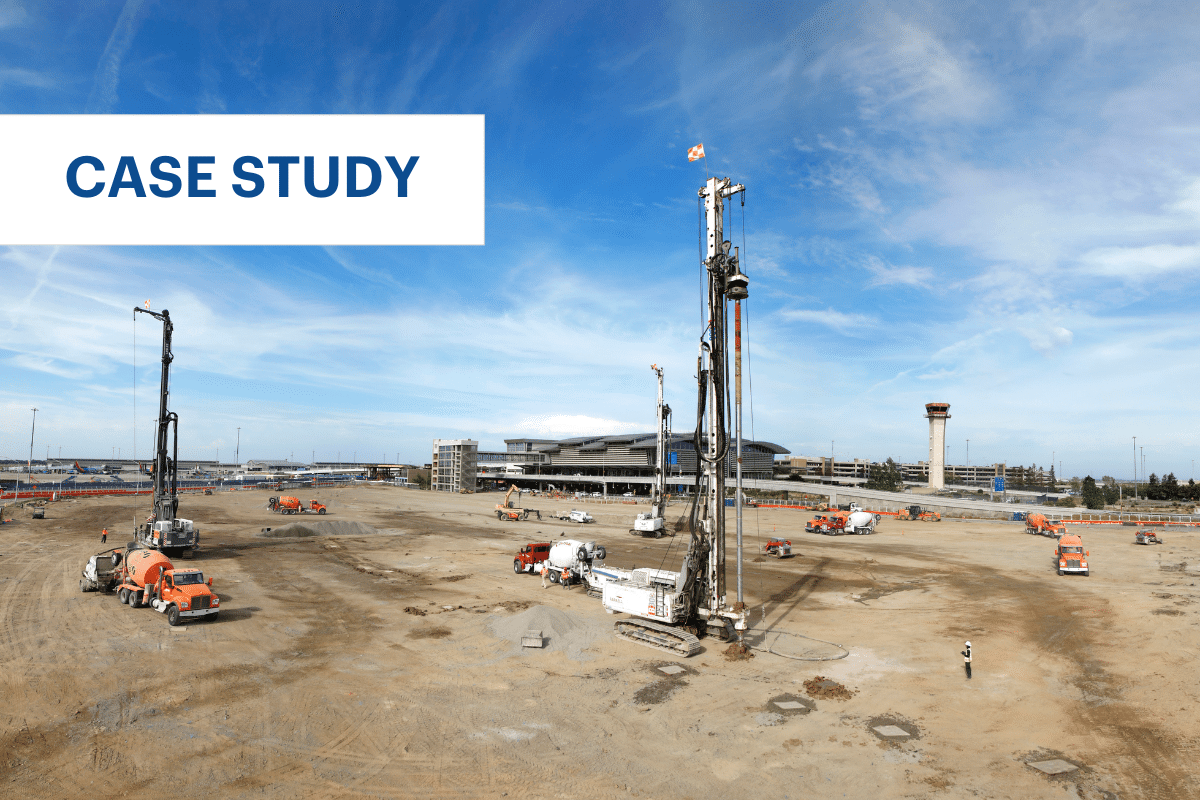

Duration of Work: 5 weeks

Subsurface Conditions: Alluvial deposits of clay and silt over sand

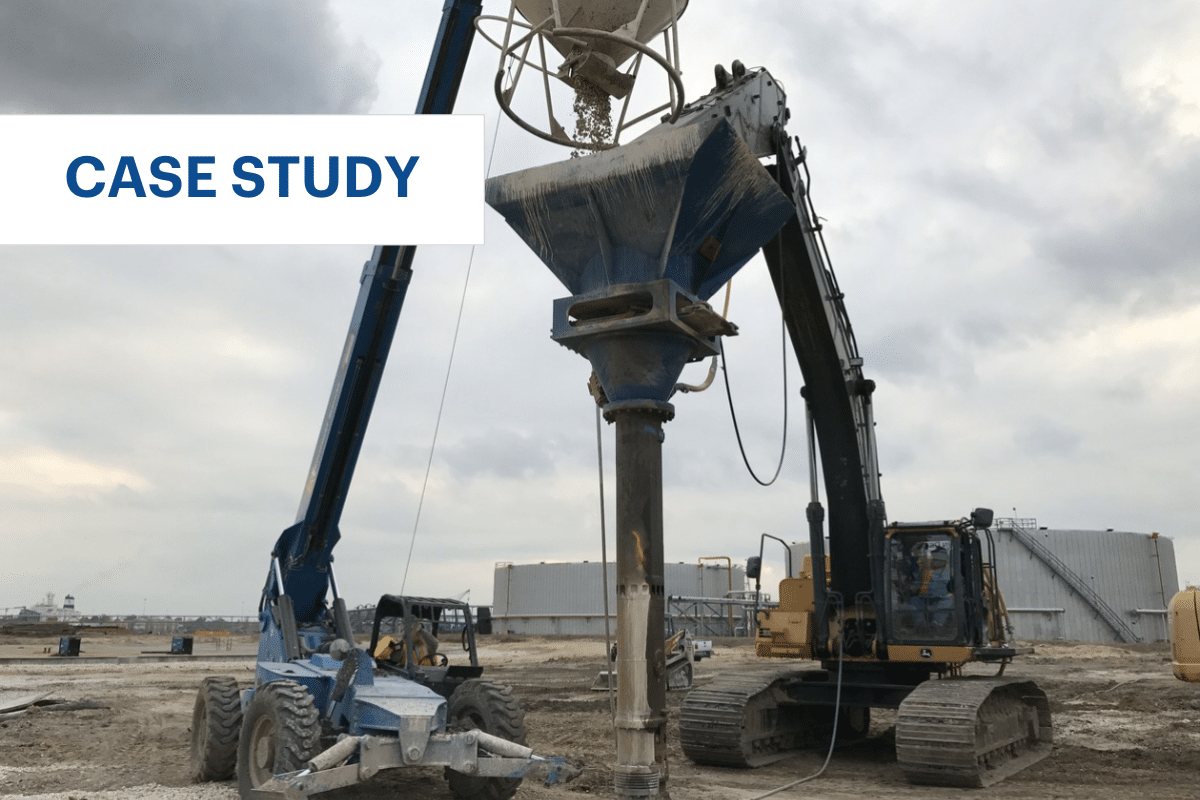

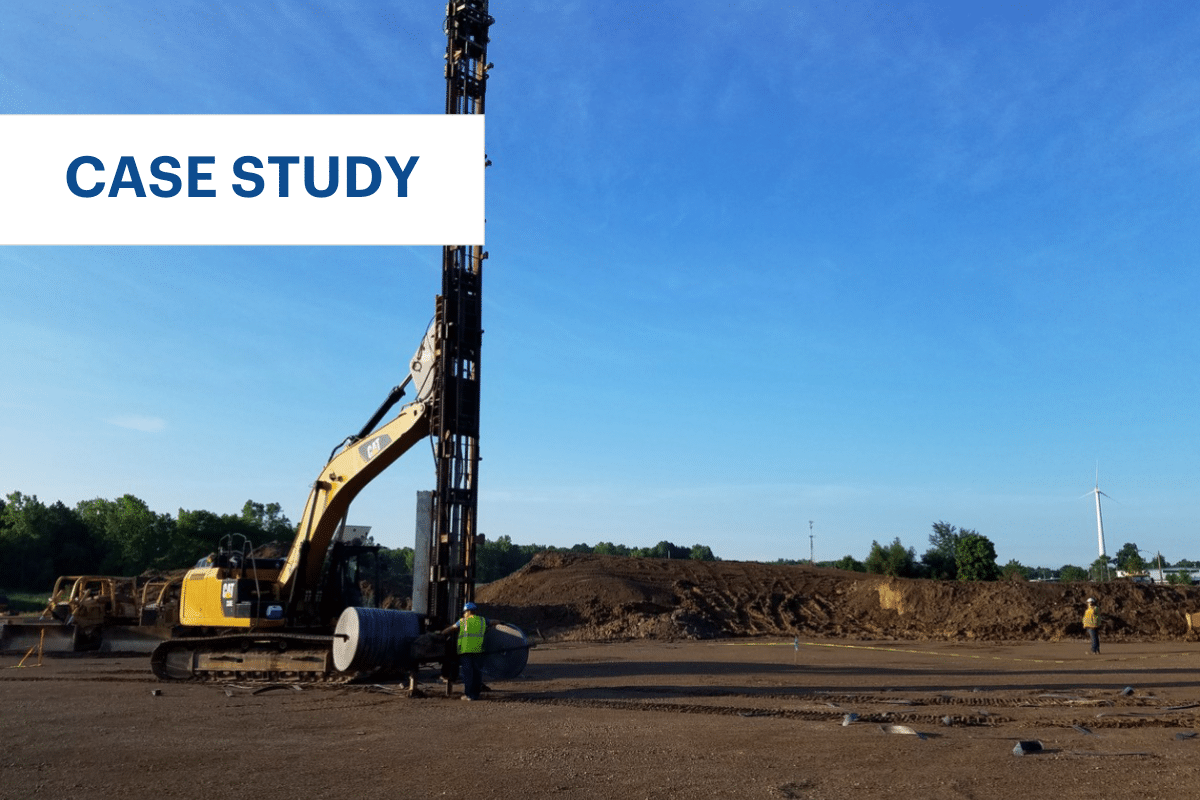

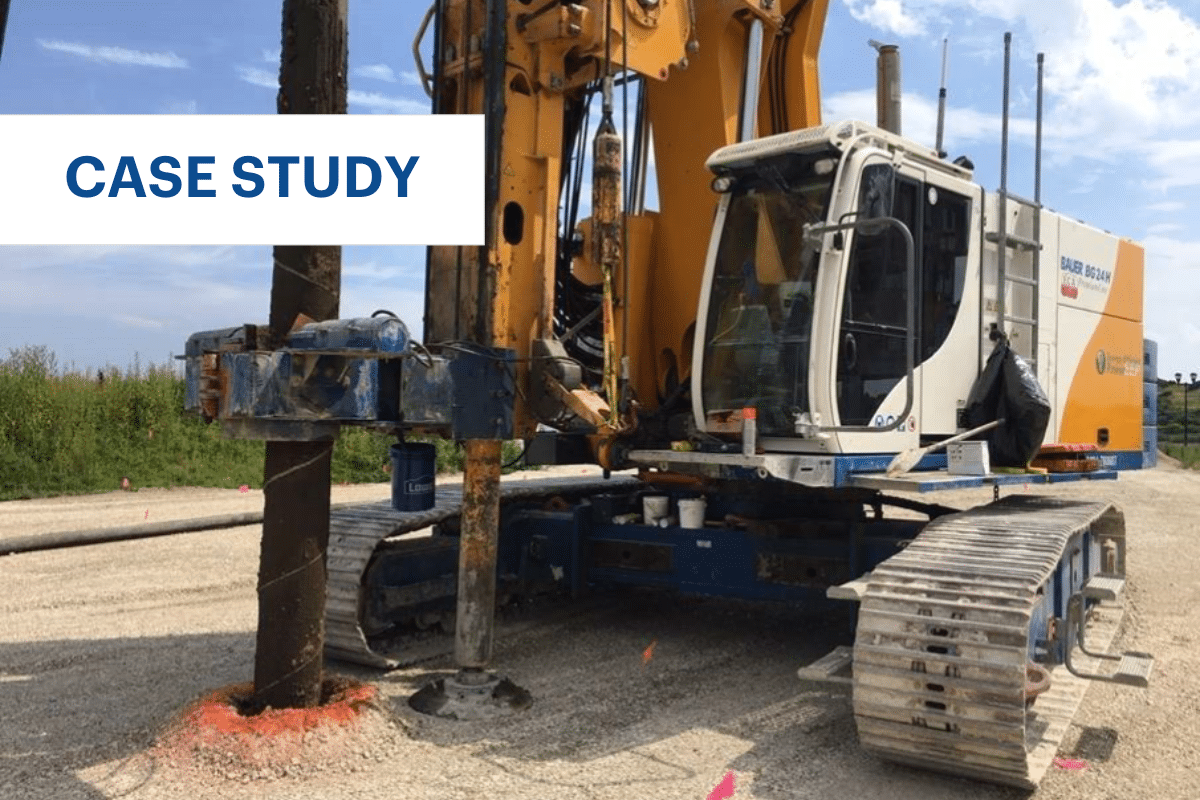

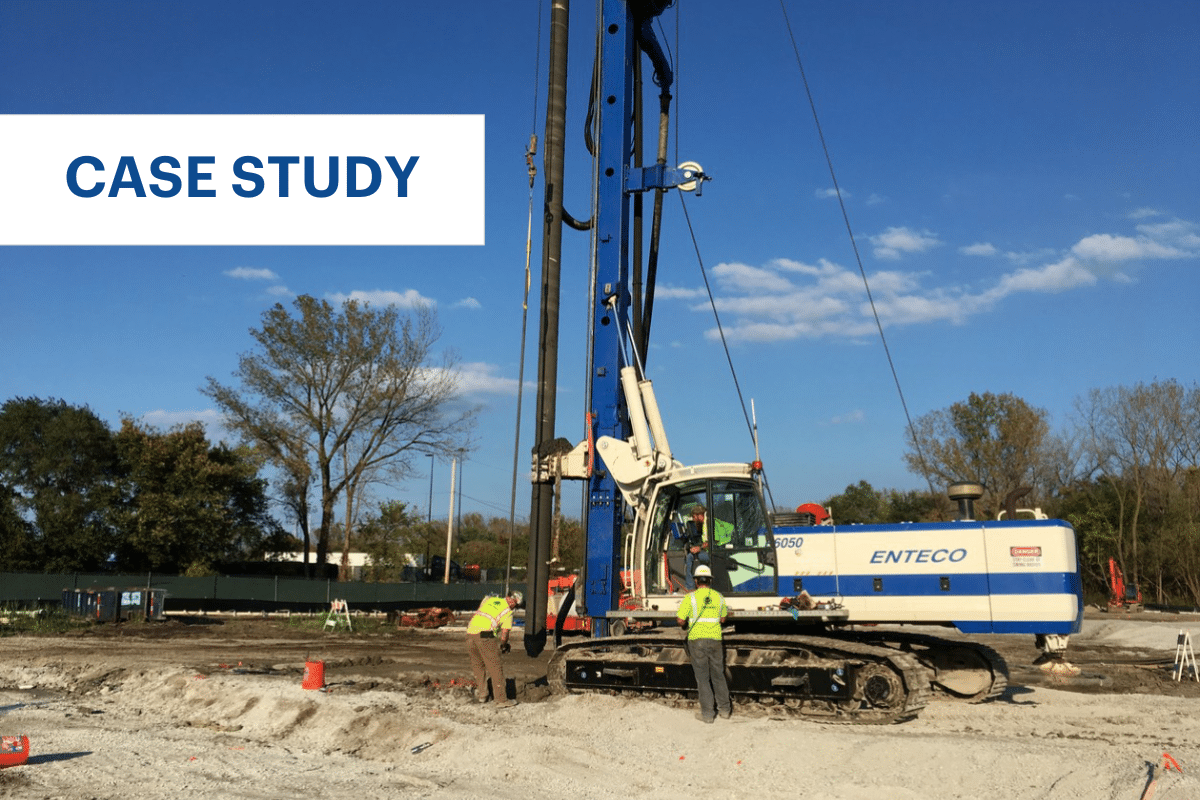

Approximate Key Quantities: 375 Controlled Modulus Column (CMC)® rigid inclusions

Project Overview:

Ground Conditions:

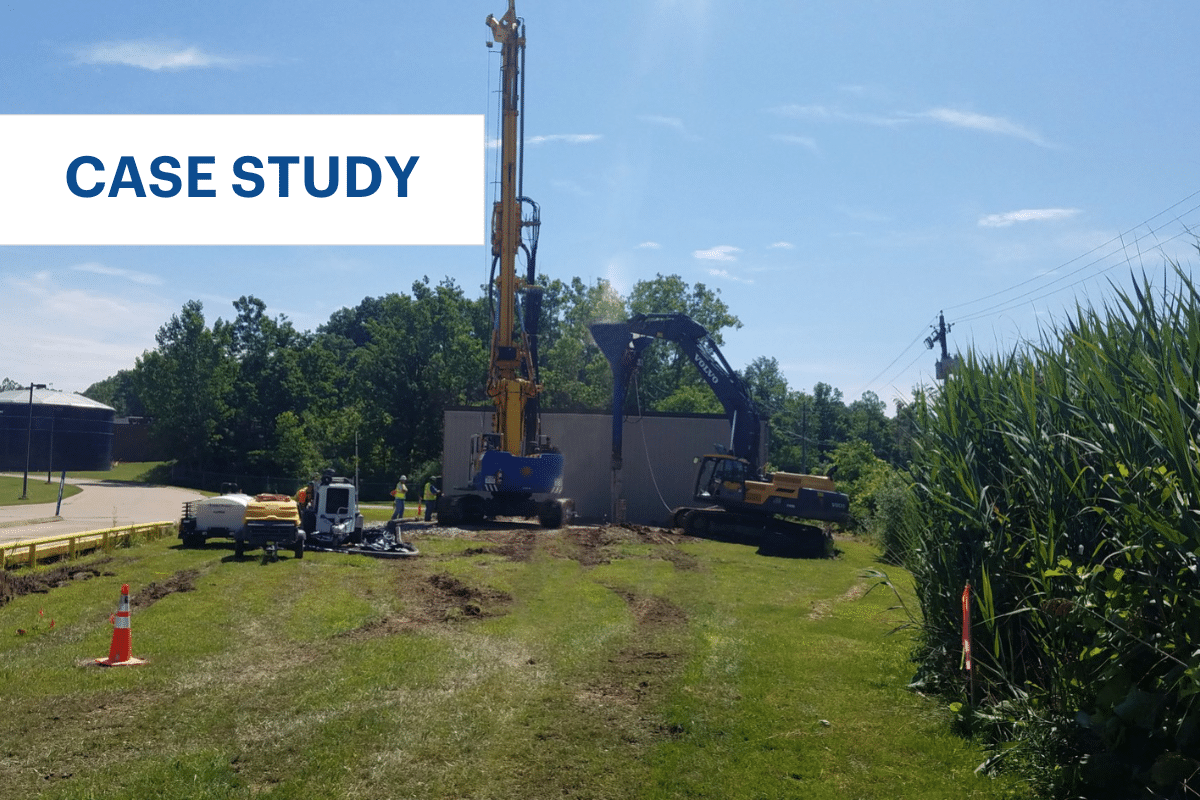

Solution:

Since Controlled Modulus Column (CMC)® Rigid Inclusion designs use a highly compacted mat of dense granular fill (Load Transfer Platform – LTP) to support large flat areas, this concept proved highly effective to replace the structural concrete mat under the insulation. The heated stone layer, the insulation board, and a concrete mat floor were placed above the LTP to support the racking. The economy of the CMC Rigid Inclusion system, and the heat break afforded by the LTP, made both a better performing foundation and an improved design regarding long-term thermal isolation of the ground.

Print this resource