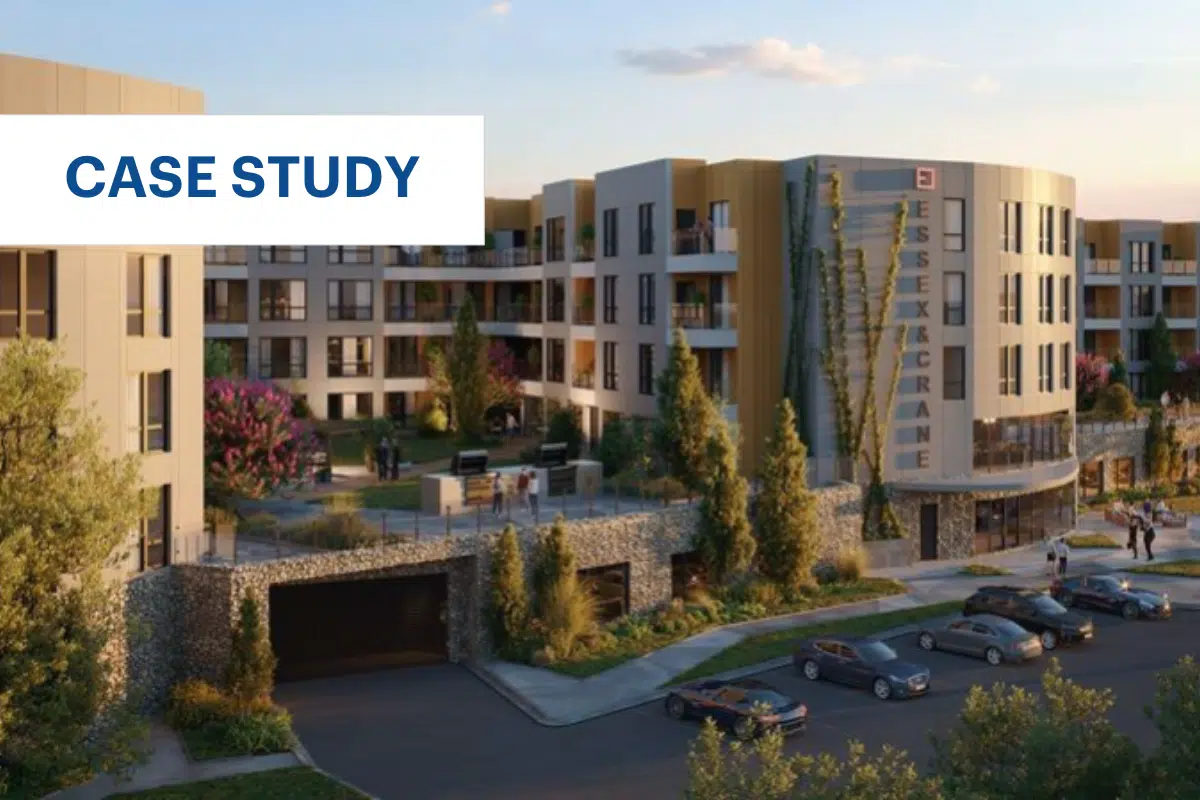

Walnut Lane Golf Club

Walnut Lane Golf Club

Project Details:

Owner: PJ Dick

General Contractor: PJ Dick

Date of Work: April 2024

Engineer: Reuther + Brown

Approximate Key Quantities: Stone Columns - 34 EA.

Description:

As part of a $2.5 million project to expand the First Tee program in the greater Philadelphia area, focusing on enhancing the facilities at Walnut Lane Golf Club; aggregate piers were installed to help address unique existing soil conditions to support the expanding development. The expansion added a golf simulation room and a food service area to the south and west sides of the existing First Tee building, providing new amenities for participants and visitors.

Ground Conditions:

Beneath the fill lies schist bedrock from the Wissahickon Oligoclase Mica Schist formation. The original First Tee building at Walnut Lane Golf Club was constructed on a caisson foundation system. For the new addition, the project team opted for a different approach, choosing to design and install aggregate piers rather than extending the deep foundation system.

Solution:

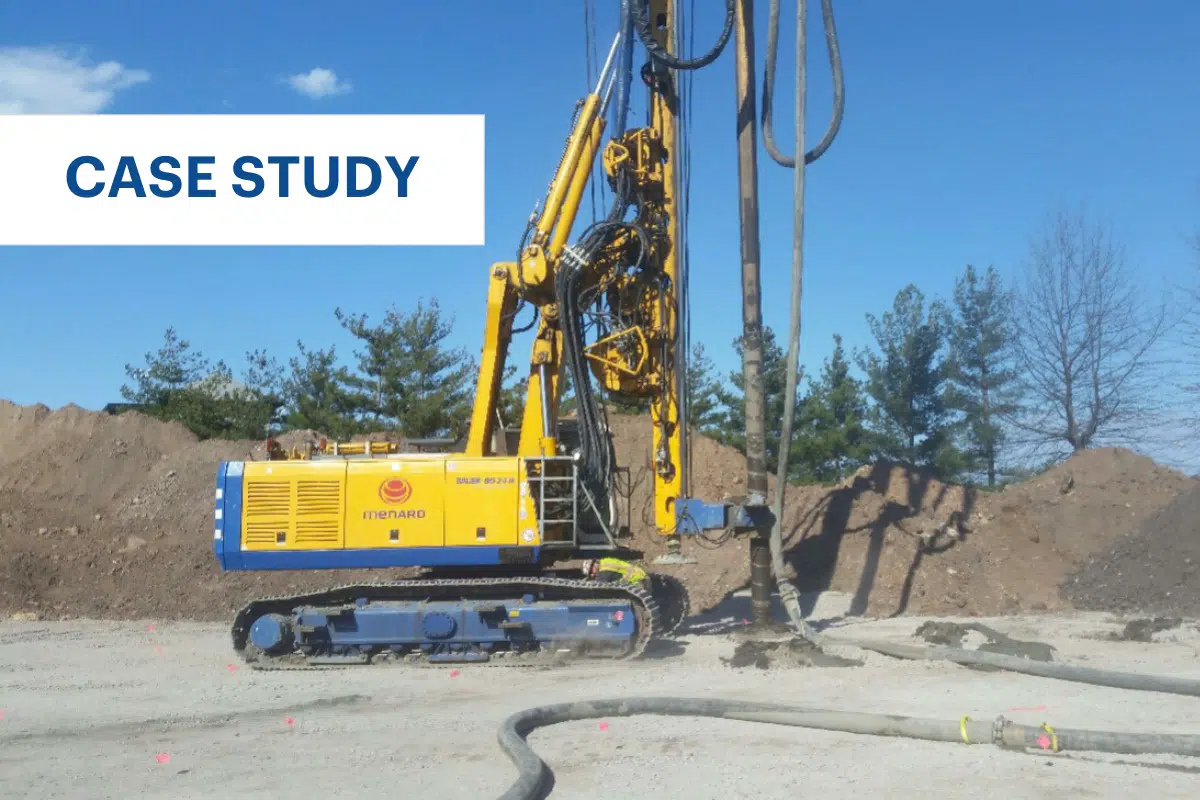

Given the variable and inconsistent fill conditions, the existing soil was deemed unsuitable for supporting the new expansion. To address this, Menard was contracted to design and install 34, 18-inch-diameter aggregate piers to support the spread and strip footings of the new building. The aggregate piers were engineered to extend into or beyond the fill, effectively preventing differential settlement that could result from the inconsistent ground conditions.

Due to the presence of rock and boulders within the fill, each aggregate pier location was predrilled to a depth of ~12 feet using an 18-inch dia. continuous flight auger (CFA). Once predrilling was complete, an aggregate pier rig installed the aggregate piers using a standard compaction lift pattern, ensuring stability and uniform support. Thanks to efficient planning and execution, Menard completed the work in just two days. The first day was dedicated to mobilizing equipment and predrilling all designated aggregate pier locations. On the second day, all 34 aggregate piers were installed, marking a swift and successful completion of the project.

Print this resource