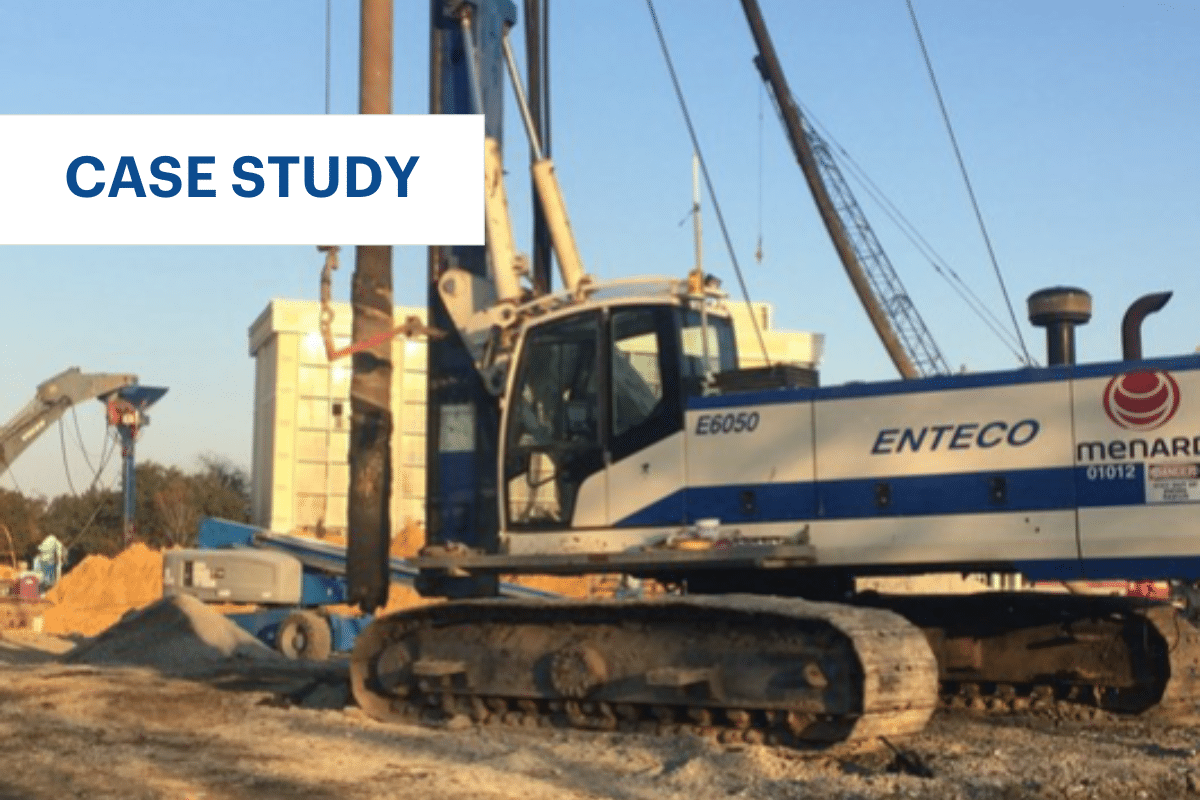

WestEdge Infrastructure

WestEdge Infrastructure

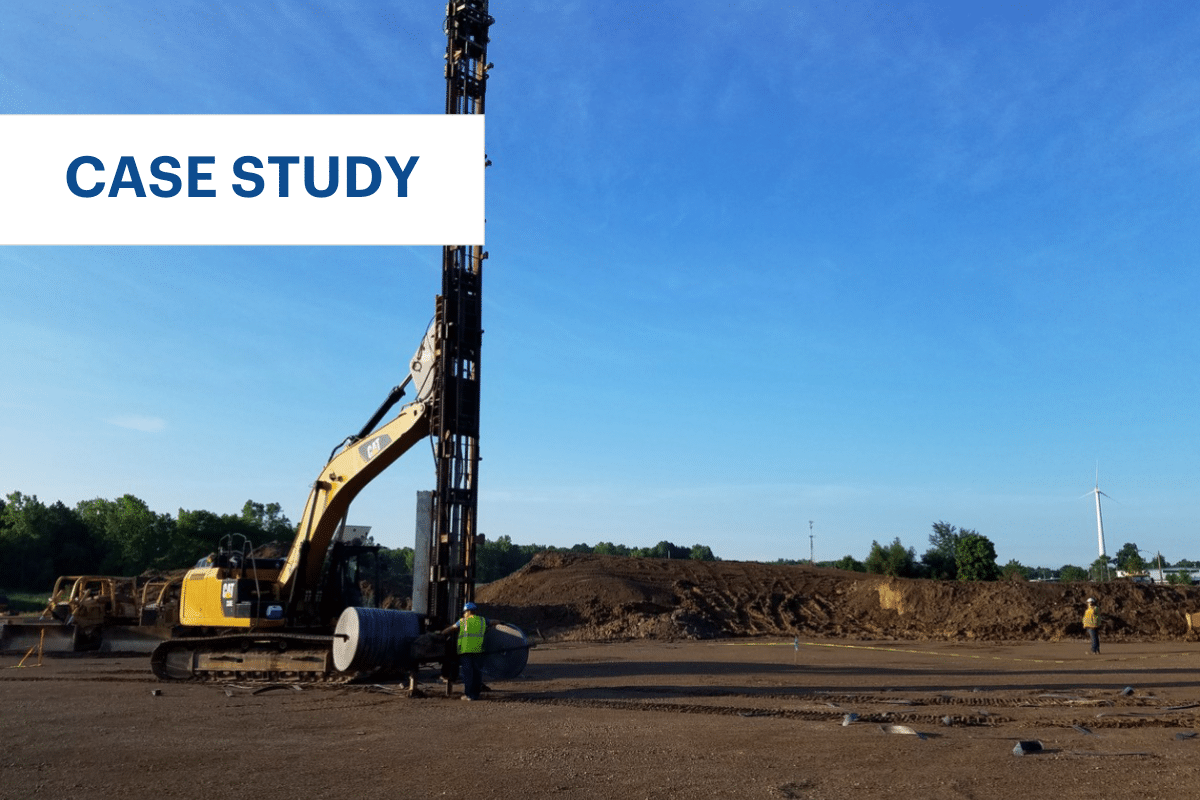

Project Details:

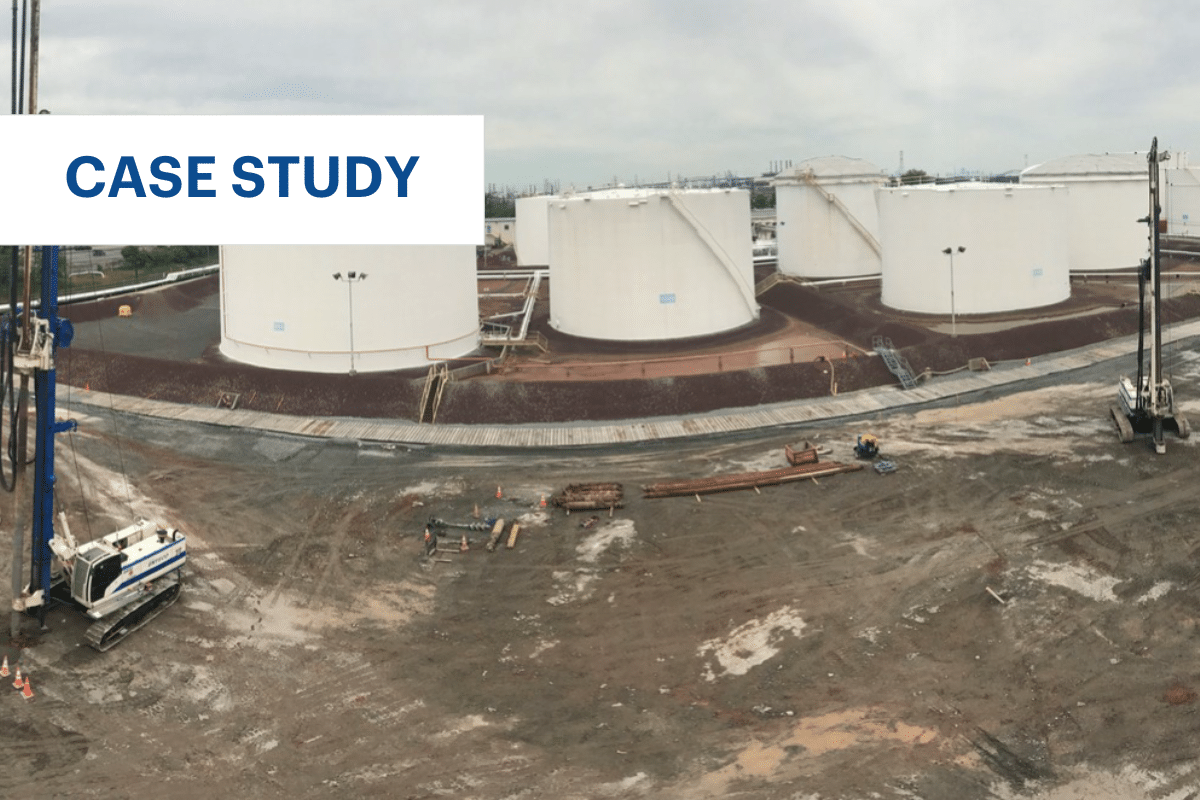

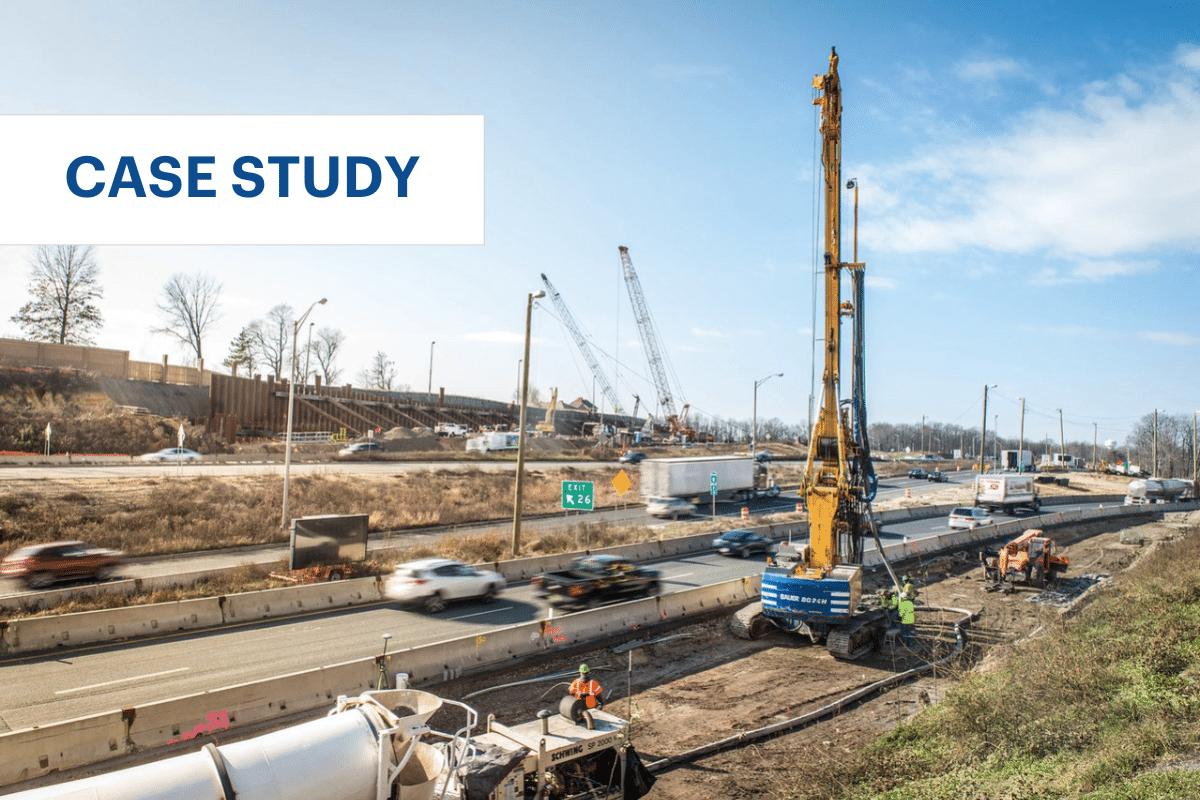

Owner: City of Charleston

General Contractor: Trident Construction

Date of Work: July 2016 - February 2017

Engineer: S&ME Inc.

Approximate Key Quantities: Controlled Modulus Columns (CMC) - 1500 EA and Bi-modulus columns (BMC)® - 600 EA

Description:

Ground Conditions:

Solution:

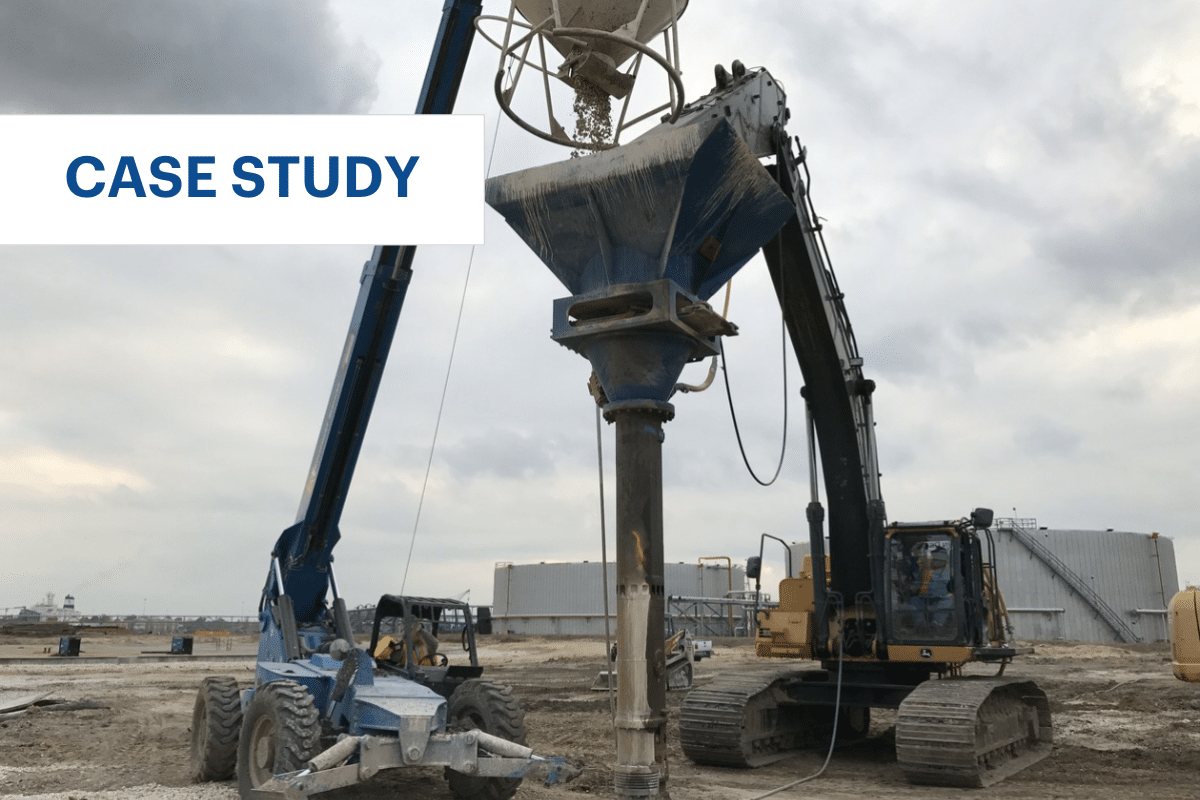

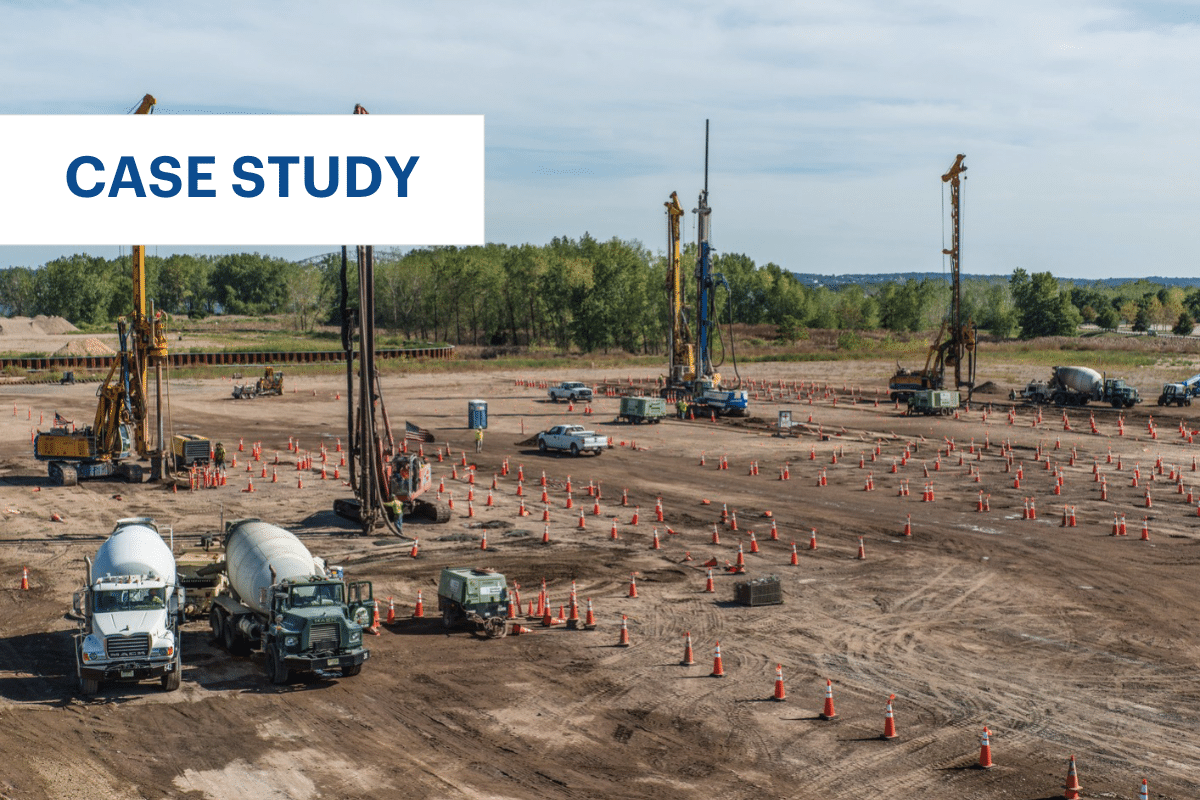

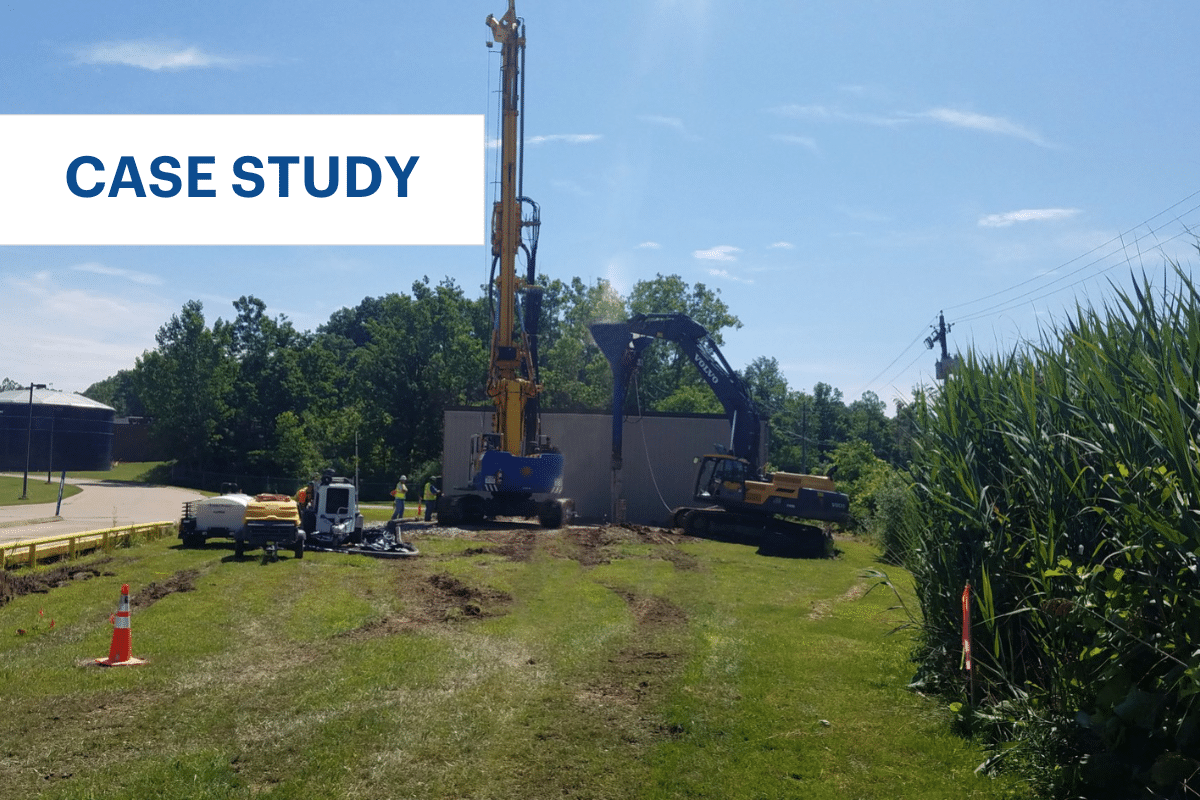

During project development, USW teamed with Trident Construction to provide a design-build solution to the potential settlement issues resulting from construction of the new embankments. USW also supported a large box culvert, several other utilities, and multiple retaining walls as part of the ground improvement scope.

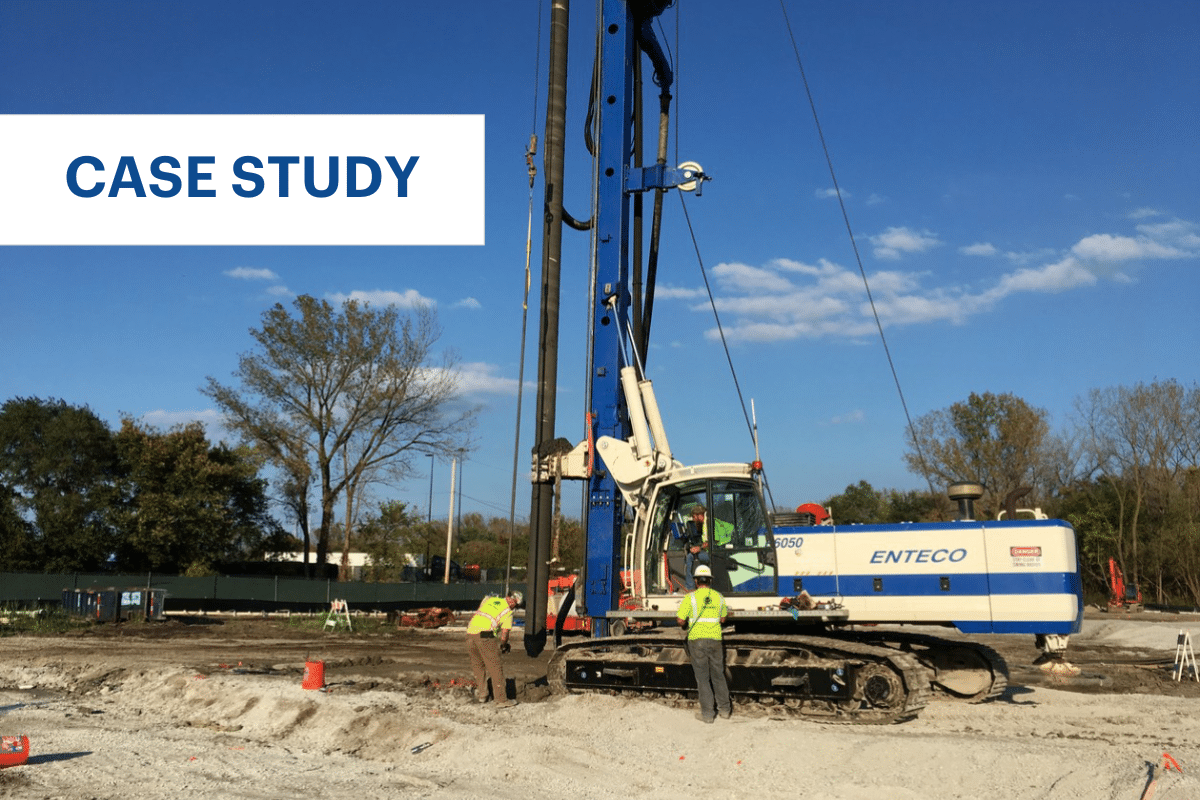

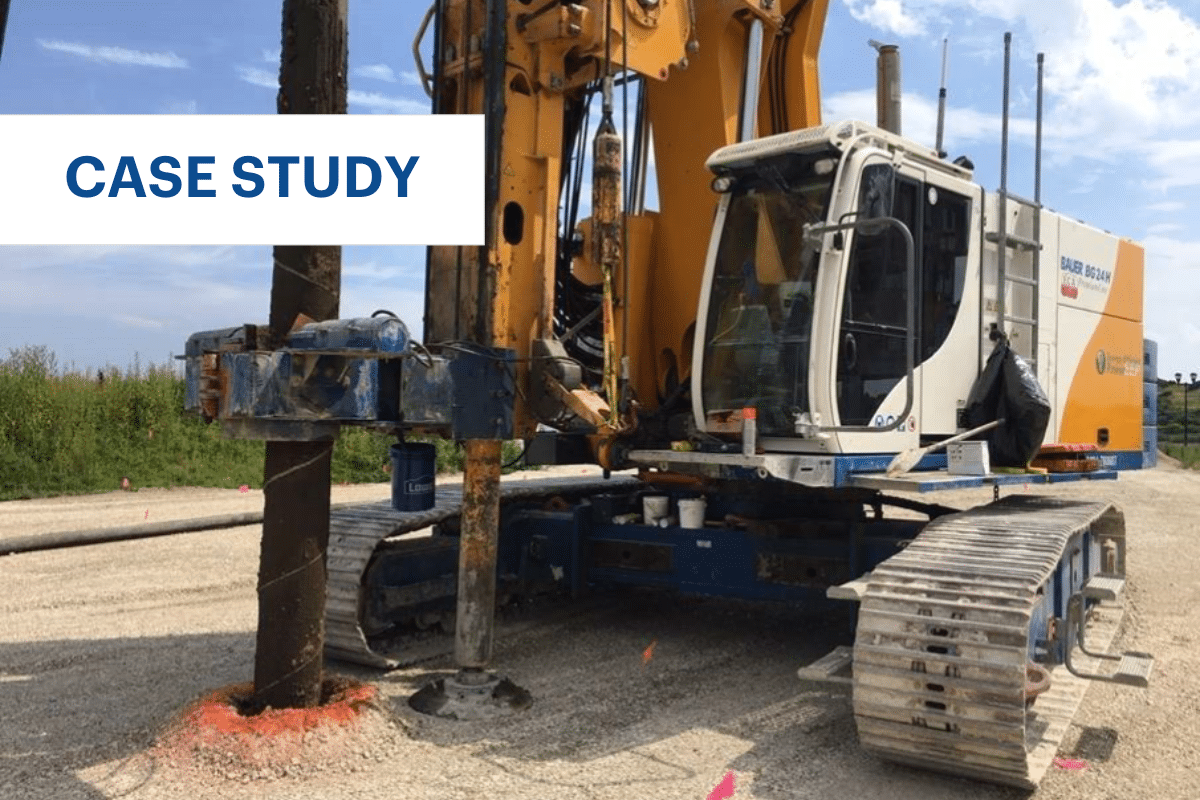

For the majority of the site where the new roadway fill exceeded five ft, CMC Rigid Inclusions were installed in a grid pattern to transmit loads below the compressible soil and into the competent Cooper Marl bearing layer. For the locations where the new roads sloped down to meet the existing street level, USW installed BMCs instead.

The BMCs consisted of a CMC rigid inclusion base extended through the very soft marsh soil with a vibro stone column cap on top, which prevented hard points from developing below the pavement. This tailored approach limited differential settlement and reduced the required thickness of Load Transfer Platform at the

base of the embankment.

The ground improvement solution allowed the embankments to be constructed immediately following CMC and BMC installation, without a waiting period or surcharging.

Print this resource