Wild Plains Wind Farm

Wild Plains Wind Farm

Project Details:

Owner: NextEra Energy Resources

General Contractor: Mortenson

Date of Work: July 2024

Engineer: Barr Engineering

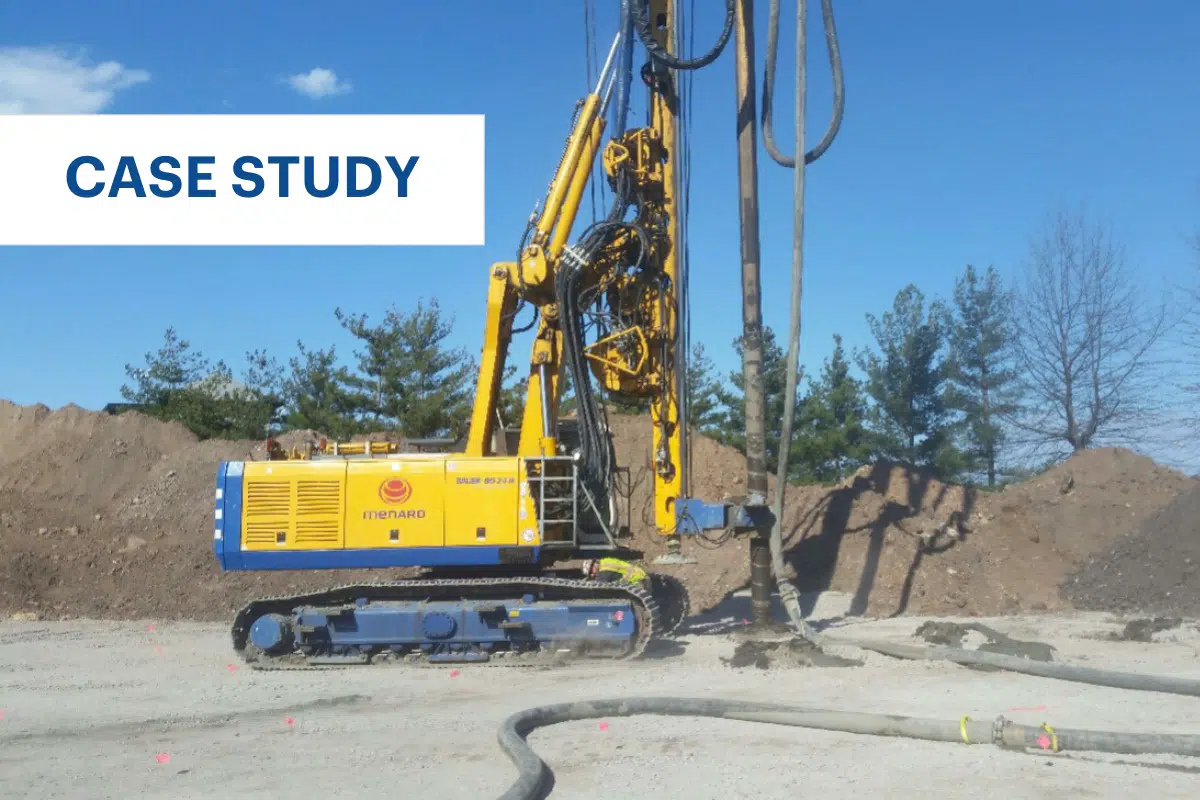

Approximate Key Quantities: Controlled Modulus Column (CMC)® rigid inclusions - 477 EA.

Description:

As part of its expanding presence in the renewable energy sector, NextEra Energy proposed the construction of 109 wind turbines spanning approximately 25,000 acres across Sumner County, Kansas. The project was divided across US Highway 160, with 66 turbines located to the north of the highway and 43 to the south. This facility will generate 307 megawatts of clean energy, contributing millions in additional tax revenue. The generated power will feed into the Southwest Power Pool, which serves electricity across 14 states.

The massive turbines produce significant dynamic forces, which exert eccentric loads on the concrete foundations, depending on the wind direction. To ensure proper foundation support, at least one soil boring or cone penetration test was conducted at each turbine location. Due to the vast area covered by the project, soil conditions varied significantly across the site. While most of the turbine sites had adequate soil bearing capacity, four sites encountered soft to very soft clay layers, posing challenges for foundation design. Additionally, the clay exhibited potentially “sensitive” characteristics, meaning the soil strength could be compromised if disturbed. Aggregate piers are typically used to improve soft clay beneath wind turbines, but the sensitivity of the clayvlayers raised concerns about whether proper compaction could be achieved. Several turbine locations also featured karstic voids within the bedrock. Given the large influence zone of the turbine foundations, these voids created a risk for differential settlement.

Ground Conditions:

The site was primarily composed of alluvial deposits over shale bedrock. The alluvium mainly consisted of leanto fat clay, with the softer deposits exhibiting high plasticity and potential sensitivity. In some locations, the water table was as shallow as 15 feet below grade, meaning it was only 3 feet below the bottom of the foundation due to the substantial thickness of the supporting mat. Additionally, some areas of the rock contained shallow evaporite rock (gypsum), which raised concerns about the presence of karstic voids.

Solution:

To address the challenges of soft clay and the potential loss of strength, Menard developed and designed a Controlled Modulus Column (CMC)® rigid inclusion solution for the four turbines with the most problematic soil conditions. Unlike aggregate piers, CMCs do not rely on the surrounding soil for capacity, which allowed them to effectively transfer the turbine loads to the underlying bedrock, even if the sensitive clay lost its capacity when disturbed. Menard designed and installed 477 CMCs for the four turbine foundations, with depths varying depending on the depth of the underlying bedrock. Menard used on-board Automated Monitoring Equipment (AME) to track the installation of each CMC and ensure proper embedment into the bearing layer. Additionally, Menard performed an instrumented static load test at the most challenging turbine location to verify the capacity and tip movement of the elements. The primary on-site challenge was the 13-foot excavation required to create a working platform for Menard’s equipment. This meant working at a lower elevation than the surrounding grade, necessitating dewatering, subgrade preparation, and ongoing coordination. Menard worked closely with the project general contractor to ensure a safe and stable platform at each site. Despite the challenges, Menard successfully completed all four turbines—including three trucked equipment moves between sites—within one month. Finally, Menard’s sister company, Nicholson Construction, performed successful rock grouting for the sites with karstic remediation. This helped mitigate the risk of differential settlement due to potential voids within the gypsum layer.

Print this resource